Vibration cannot be avoided in the mechanical cutting process. Processing vibration results from the interaction between the cutting tool and the workpiece during metal cutting.

Its origin and development are intrinsically linked to the dynamic characteristics of the cutting process and the nature of metal cutting itself.

Consequences of Tool Vibration on the Machined Surface

The tool’s vibration against the workpiece’s machined surface can cause vibration on the machined surface itself. This vibration seriously impacts both the machining accuracy and surface quality.

Additionally, it can lead to severe wear on the cutting insert, which may ultimately make continued cutting impossible.

Health and Safety Impacts of High-Frequency Vibrations

High-frequency fluctuations that occur during the cutting process can result in noise pollution.

This noise not only disrupts the working environment but can also adversely affect operators’ physical and mental health.

One type of vibration—forced vibration—is caused by disturbance forces within the machine.

Forced Vibration and Its Causes in Cutting

In cutting operations, forced vibration refers to unavoidable interruptions.

This is because the constant size and direction of the tool-to-workpiece contact influences the radial thickness of the slice.

As a result, the forced vibration process is always present in cutting operations.

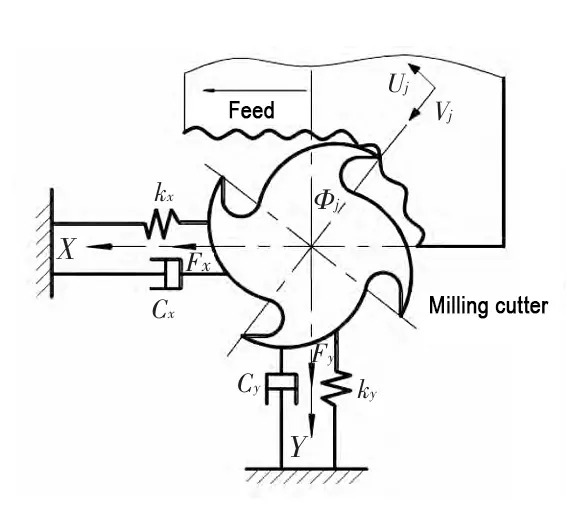

Compared to turning, milling involves a more complex vibration mechanism, and its stability analysis requires consideration of more influencing factors..

Self-Excited Vibrations: Regenerative Chatter

Self-excited vibrations, or chatter, are usually due to “regenerative feedback” within the system.

This vibration can often be replicated and amplified, which is very harmful.

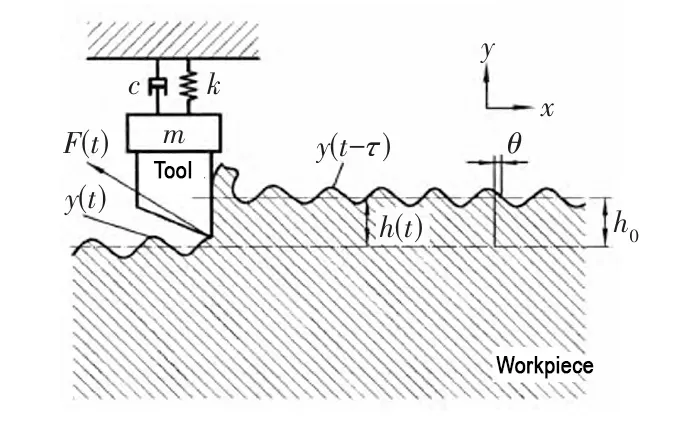

Figure 1 shows the mechanism of regenerative chatter. The vibration triggered by the regenerative effect of vibration patterns is called regenerative cutting chatter or self-excited vibration.

How Regenerative Chatter Forms

Specifically, processing produces an uneven surface. The cutting thickness becomes inconsistent and irregular when the tool performs a second or subsequent pass on this surface.

As a result, the cutting thickness varies, causing sudden changes in cutting force. This uneven cutting action between the tool and the workpiece leads to vibration.

The vibration creates a pattern on the processed surface known as a vibration pattern. If this effect continues to grow, it results in the formation of chatter.

Historical and Theoretical Insights into Chatter

Taylor introduced the concept of chatter in 1901, and scholars from various countries have conducted in-depth studies on the formation of its mechanism and stability.

The book “Machine Tool Vibration” provides a detailed description of the regeneration chatter model.

It proposes that the main factor causing the periodic changes in instantaneous cutting thickness is “regenerative vibration.”

Fig. 1 Dither mechanism

Cutting stability analysis

(1) Cutting processing is a vital production role.

In mechanical engineering programs, machine production mainly focuses on key product parts.

Generally, the production of machine parts uses technologies such as casting, forging, stamping, and welding.

These methods are typically applied to produce blanks and semi-finished products. This initial stage plays a vital role in the overall parts production process.

Advancements in Manufacturing and Material Efficiency

As the manufacturing industry advances, technology and processes progress and improve.

Metal cutting and processing increasingly produce parts closer to the final desired size, significantly reducing the need to remove excess material during metal processing.

Technologies such as casting and forging can be used to create products that require minimal machining.

This approach significantly improves part production efficiency and helps reduce processing and production costs.

Rapid Prototyping in Machine Building

In addition, the rapid production of prototypes in machine building is also a technical method, usually used to make mold parts, usually in combination with other production measures employed in machine building.

Effect of Tooth Count on Chatter

According to machining production experience, increasing the number of teeth makes the cutting system more prone to chatter.

Having more teeth that are closer together can improve production efficiency and enhance the quality of the machined surface.

However, dense teeth can also cause difficulties in chip discharge. The cutting tool is the main factor influencing chatter stability, which changes the frequency response at the tool tip during the cutting process.

Tool Rigidity and Chatter Control

At the same time, the tool’s rigidity also affects the chatter. Increasing the milling cutter diameter can improve the tool’s rigidity. Choosing a large-diameter milling cutter is beneficial for improving cutting chatter.

With the increase of tool overhang length, the dynamic stiffness of the tool tip position decreases, and the unstable region of the cutting system increases.

Milling Cutter Adjustment to Avoid Vibration

When milling metal, adjust the length of the cutter’s deep card spring according to the cutting depth.

Shorten this length as much as possible to enhance the rigidity of the milling cutter during milling. Avoid overextending the cutter to prevent vibration.

The larger the milling helix angle, the greater the axial force on the system, and the greater the cutting resistance.

Workpiece Material and Cutting Stability

The material’s influence on cutting stability is mainly reflected in the consistency of the dynamic cutting force on the workpiece.

Specifically, it depends on whether the dynamic cutting force that excites chatter remains constant and unchanging.

In general, during metal machining, a greater dynamic cutting force indicates higher material hardness.

This also suggests that the material has poorer plasticity. As a result, the cutting becomes more difficult, and the material is harder to process.

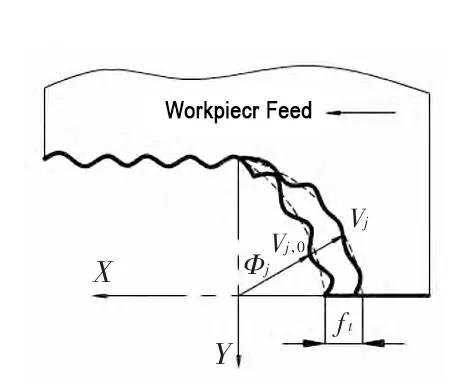

Milling Modes and Their Impact on Stability

The impact of metal milling processing modes on cutting stability is mainly reflected in the selection of different tool travel methods.

When processing the same metal raw materials, the two approaches—climb milling and conventional milling—will result in different actual cutting force coefficients.

These differences lead to slight variations in the cutting stability prediction between the two methods.

Since static milling does not generate cutting force, it does not affect cutting stability. As a result, static milling does not produce chatter. This is illustrated in Fig. 2 and Fig. 3.

(2) cutting tools.

The application of cutting tools in the cutting process of machine tool products is crucial for improving the technical level and quality of those products.

It also plays a key role in enhancing production efficiency. The tool’s main performance usually significantly impacts the cutting and processing stages.

This directly affects product quality, production efficiency, and production costs. Therefore, tool performance has a substantial influence on the manufacturing process.

Purpose and Principle of Machine Cutting

In machine manufacturing, cutting is a production method that uses practical cutting tools to cut excess metal material from the parts produced to obtain the desired size, style, and appearance quality of the metal product.

In machine cutting production, the key is to use the cutting position of the tool to perform cutting on metal parts.

This creates the effect of completing the cutting and manufacturing process. The effectiveness depends on the tool’s cutting action and impact reduction during cutting.

These two aspects—tool performance and minimized impact—influence cutting efficiency. Under these effects, machine cutting enables the production of metal products.

Factors Influencing Milling Tool Selection

Metal milling machining involves cutting tools, according to the processing object material, the number of batches of products, the production cycle, and several other factors.

Continuous Improvement in Tool Performance

The critical role of the tool in production and processing is clear and widely recognized by the machining industry.

As technology continues to advance, tool production technology is also being upgraded. Improvements are being made in several key aspects of tool performance, including material, rigidity, wear resistance, and heat resistance.

These enhancements aim to optimize tools and improve their overall quality.

Tool Innovation Driven by Market Demands

At the same time, tool manufacturers are increasing their R&D efforts in response to changing market demands.

This has led to a shorter performance transformation cycle for tools, allowing them to adapt more quickly.

Manufacturers now adjust tool design based on product batch sizes and production timelines.

As a result, tool performance is improving continuously, with better cutting capabilities to meet the requirements of modern machining and manufacturing.

(3) Chattering in processing.

During the production process, machine and equipment movement can have a very negative impact on manufacturing operations.

This movement causes operator fatigue and reduces production speed and product quality.

Equipment Vibration and Workpiece Damage

In addition, it poses a significant threat to the safety of the production process and equipment.

In addition, during the manufacturing process, the equipment’s dynamic behavior may damage both the equipment and the workpiece to some degree.

This damage reduces the vibratory cutting machine’s working time. During processing, the workpiece may generate a vibration-induced dynamic cyclic force.

This force can sustain a non-damped vibration phenomenon. Such situations often occur during machining processes.

This persistent vibration is not conducive to maintaining product quality and lowers overall production efficiency.

Chatter in Dynamic Cutting Operations

Usually, during the cutting process, chatter occurs in dynamic metal cutting operations.

This affects the cutting process’s thickness and the workpiece’s surface quality.

Chatter can be caused by guideway vibration and may lead to a crawling phenomenon.

At the same time, it impacts the spindle’s radial rotary accuracy. Cutting chatter seriously affects the tool and machine tool’s lifespan.

Strategies to Control Chatter and Vibration

In the cutting process, when significant chatter occurs, you should immediately observe the processing situation.

Check both the tool blade and the workpiece carefully. If no problems are found after inspection, reduce the feed rate, cutting thickness, and cutting depth to control the vibration.

This helps avoid rapid tool wear and excessive noise. At the same time, it ensures processing quality, prolongs the service life of both the tool and the machine tool, and reduces noise pollution.

This also protects the physical and mental health of operators and nearby personnel.

Vibration in milling is a phenomenon unfavorable to production for the following reasons:

- Related to the workholding fixtures associated with workpiece machining.

Chattering during machining affects the position of the fixture and the position and surface quality of the workpiece.

Vibration of the surface produces vibration marks on the surface, which seriously affects the performance of the machine parts.

- Vibration causes the tool to move relative to the workpiece, regularly affecting the cutting part, cutting angle, and cutting force.

Each component of the process system experiences dynamic load effects. As a result, the tool wears easily and, in severe cases, the blade may collapse.

The machine tool’s connecting parts can become damaged. In extreme situations, this damage can prevent the processing from continuing.

- High-frequency vibration in the milling process, sometimes accompanied by ear-piercing screams, results in noise pollution, endangering the operator’s physical and mental health.

- It is sometimes necessary to reduce the amount of cutting to avoid or reduce vibration.

However, this prevents the machine tool’s working performance from being fully utilized, restricting the improvement of processing efficiency.

Stabilization measures

According to the milling process, analyzing the factors that impact processing vibration is essential.

> Understand the principles

First of all, you must understand the principles of vibration.

Summarize the various factors causing vibration based on the actual milling process.

Combine this understanding with the principles of vibration during cutting. Then, find practical solutions to develop the milling machining process and take appropriate measures.

> Regenerative Vibration Theory

Regenerative vibration theory explains that during two different machining processes, a phase difference and vibration displacement occur.

These factors cause the cutting thickness to become inconsistent, which leads to vibration.

> Modal Coupling Vibration Theory

In addition, the principal phenomenon of cutting chatter in the machining process without regenerative chatter conditions is called modal coupling vibration theory.

Taking cutting thread processing as an example, the vibration occurs because the two cutting actions before and after do not overlap.

The phenomenon of modal coupling vibration causes this vibration. In short, controlling the cutting process is essential based on the reasons for cutting and chatter theory.

> Key Parameters for Controlling Vibration

You can adjust factors such as the machine tool’s spindle speed, cutting speed, cutting width, tool diameter, and material appropriately.

These adjustments help meet processing requirements and avoid vibration problems during cutting.

Adjusting the spindle speed of the cutting machine tool has the most obvious effect on controlling cutting chatter.

> Benefits of Vibration Control

Using this technology to control chattering can significantly reduce the various adverse effects caused by vibration.

By studying cutting vibration, using scientific and reasonable cutting tools and fixtures, and developing efficient machining process programs, enterprises can reduce production costs and improve economic efficiency.

This can be considered from the following aspects:

(1) cutting tools.

A larger arc radius of the tip and a smaller side angle of the polished edge can reduce the remaining area.

Within the limits of the process requirements, choose a milling cutter with a larger diameter whenever possible.

At the same time, keep the tool shank extension as short as possible. This helps maintain the spindle’s stability in the radial direction.

(2) Processing blank or semi-finished material.

In testing and analyzing various raw material properties, the plasticity of the raw material and the roughness of the surface are two factors that affect the quality of the finished product.

Therefore, they can be analyzed one by one. Heat treatment is carried out before machining for plasticized raw materials, such as alloy steel and mild steel.

This treatment reduces their plasticity, allowing for a smoother finish after cutting.

(3) Reduce residual internal stress.

According to the milling process requirements, analyze and understand their performance before processing the blank and semi-finished materials.

Control the next cut, feed, and retraction processes in designing the processing program to avoid transient impacts.

This helps ensure the tool processes with a uniform feed.

Ensure there is sufficient cutting fluid for cooling, so the temperature of the processed surface and the surface to be processed remains the same.

This prevents the generation of residual internal stresses and reduces vibration during the cutting process.

As a result, the surface roughness of the workpiece decreases, ensuring the surface quality of the workpiece.

Conclusion

To analyze and research the vibration problem in the machine’s production process, relevant and effective technologies can be used for improvement, prevention, and control.

These technologies help reduce the risks that cutting vibrations pose to the manufacturing industry.

They can also be applied to improve machines and equipment, implementing measures to minimize vibration.

This ensures the cutting process’s quality and maximizes the machine tool’s performance.

As a result, it enhances production quality and helps maintain the enterprise’s profit margins.

FAQ:

Vibration in mechanical cutting results from the interaction between the cutting tool and the workpiece. It is influenced by the dynamic characteristics of the machine system, tool rigidity, workpiece material, and cutting conditions. These vibrations are inherent to metal cutting and can never be fully eliminated, only minimized.

Tool vibration creates unwanted patterns on the machined surface, leading to reduced dimensional accuracy and poor surface finish. In severe cases, it accelerates tool wear, damages inserts, and may even make further machining impossible.

High-frequency vibrations generate noise pollution, which negatively impacts the work environment. Prolonged exposure may harm operators’ physical and mental health, increasing fatigue and stress in machining workshops.

Forced vibration is caused by disturbance forces within the machine system during cutting. It occurs because of constant tool-to-workpiece contact and fluctuations in chip thickness. Forced vibration is always present in machining but can be controlled with proper adjustments.

Regenerative chatter, also known as self-excited vibration, occurs when uneven surface patterns from one pass influence the tool’s next cut. This feedback loop amplifies vibration, leading to severe surface damage, rapid tool wear, and unstable machining conditions.

Tool rigidity is critical for minimizing chatter. Using a larger cutter diameter, reducing tool overhang, and shortening clamping length improves stability. Adjusting cutter helix angles and choosing appropriate feed rates also reduces vibration during milling.

The hardness and plasticity of the workpiece material strongly influence vibration. Harder materials generate higher dynamic cutting forces, making machining more difficult and prone to chatter. Proper material selection and heat treatment can enhance cutting stability.

Different milling modes, such as climb milling and conventional milling, affect the cutting force and stability. For example, climb milling often improves surface finish but may increase vibration risk. Selecting the right milling mode is key to balancing efficiency and stability.

Chatter can be controlled by adjusting spindle speed, cutting depth, feed rate, and tool geometry. Using stable fixtures, applying sufficient cutting fluid, and minimizing internal stresses in workpieces also reduce vibration and extend tool life.

Controlling vibration ensures higher machining accuracy, better surface quality, longer tool life, and safer working conditions. It also improves production efficiency, reduces costs, and protects machine tools from premature wear and damage, making it essential for sustainable manufacturing.