Manufacturing for Medical Equipment

We leverage our extensive manufacturing experience to deliver custom prototyping and parts manufacturing across industries, including the Medical field.

Our streamlined processes and competitive prices ensure a fast and cost-effective product development experience.

- Tolerances down to ±0.0004″ (0.01mm)

- Instant pricing & free DFM feedback

- ISO 9001:2015 certiified

Why do Communication Equipment Supplier Choose us?

From rapid prototyping to custom production, we streamline the manufacturing of communication devices at competitive prices.

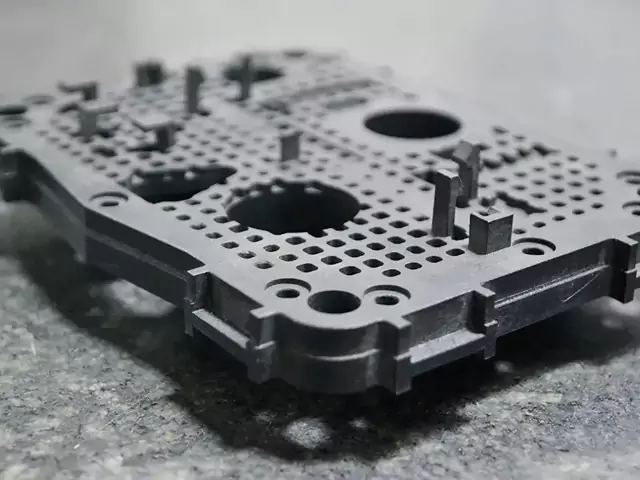

Precision Machining

Manufacturing precision parts demands sophisticated equipment, skilled operators, precise inspection tools, and more. Our capabilities enable us to produce parts with tolerances as tight as +/- 0.0004” (0.01mm). Our goal is to deliver products that meet our customers' highest expectations.

ISO Certified

As an ISO9001 certified manufacturing company, we ensure you receive high-quality automotive parts, no matter the design complexity. We guarantee that our product development adheres to internationally recognized best practices and meets all required standards.

Customizable

This is the era of personalization, so we believe that customizing products can enhance the uniqueness of your products and bring you a competitive advantage in the market. We have provided successful cases for thousands of customers. Belive us, contact us!

Fast Response

Leveraging our advanced manufacturing technology, and skilled professionals, RuiYi ensures the rapid production and delivery of your automotive parts. Faster delivery provides you with greater flexibility to improve or iterate your products, helping you stay ahead of competitors.

Quick Deliver

We can provide you with one-stop service. No matter where you are, we can deliver your products to the destination quickly, with safty and on time. We create the greatest value and satisfy for customers, think about what customers need, and serve customers wholeheartedly.

Prototyping & Production Solutions

The journey from prototype manufacturing to finished product production typically involves several key processes. In actual product development, these processes may overlap or occur concurrently, with the specific steps and sequence varying based on the product’s type and complexity.

- Conformance testing

- Thermal testing

- Power measurement testing

- Signal quality testing

- Electromagnetic interference testing

Efficiently iterate based on performance, ensuring rapid adjustments to meet standard requirements while maintaining prototype functionality.

Manufacturing Capabilities

CNC Machining for Plastic

- Geometric Tolerances: +0.1mm/100mm

- Largest Size:3000*1200*850mm

- Material: ABS, PMMA, PC, PA, and etc.

- Finsh treatmeant: Remove burrs, break sharp edges,polish, plating, brush, and etc.

CNC Machining for Metal

- Geometric Tolerances: +0.01mm/100mm

- Largest Size:3000*1200*850mm

- Material: Al alloy, brass, stainless steel, and etc.

- Finish treament: Remove burrs, and etc.

Vacuum Casting

- Geometric Tolerances: +0.2mm/100mm

- Material: ABS(DPI8150,PX5118,PX200,PX600); ABS8150,Rubber, PC, PMMA5210, PP, Silicone,and etc.

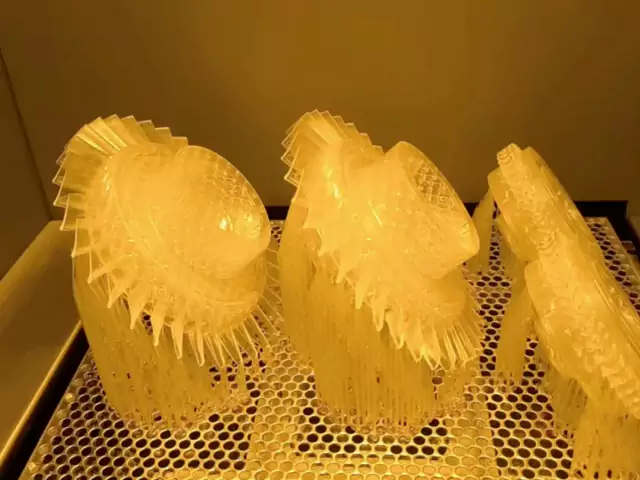

3D Printing

- SLA Geometric Tol: +0.1mm/100mm

- SLS Geometric Tol: +0.2mm/100mm

- SLA Material: ABS8000,9400,8228,ZR40, and etc

- SLS Material: PA12,PA+GF

- Size: SLA 3000*1200*850mm, SLS 580*300*300mm

Custom Prototypes and Parts

FAQ

What types of manufacturing services do you provide for the medical industry?

We offer CNC machining, sheet metal fabrication, mold making, and vacuum casting services to produce high-quality components for medical applications.

What medical components can you manufacture?

We can manufacture parts such as surgical instruments, medical device housings, diagnostic equipment components, and custom fixtures.

What materials do you use for medical manufacturing?

We work with biocompatible materials such as stainless steel, titanium, aluminum, PEEK, ABS, and other medical-grade plastics and metals.

Can you ensure the precision required for medical applications?

Yes, our advanced CNC machining and quality control processes ensure precision tolerances, typically within ±0.005mm, meeting stringent medical standards.

Do you comply with medical industry standards and certifications?

Yes, we follow industry-specific standards, such as ISO 13485 for medical device manufacturing, and ensure compliance with regulatory requirements.

What is the lead time for medical manufacturing projects?

The lead time typically ranges from 7 to 15 business days, depending on the complexity and volume of the order.

Can you produce prototypes for medical devices?

Yes, we specialize in rapid prototyping using CNC machining, vacuum casting, and other technologies to help validate medical device designs.

How do you ensure the quality of medical components?

We implement rigorous quality assurance practices, including inspections, material certifications, and testing, to meet medical-grade quality standards.

Do you offer surface finishes suitable for medical applications?

Yes, we provide surface finishes such as polishing, anodizing, passivation, and coatings to meet the functional and aesthetic needs of medical parts.

Do you handle low-volume and custom production for the medical industry?

Yes, we specialize in low-volume production and custom manufacturing to accommodate the unique needs of medical device manufacturers.