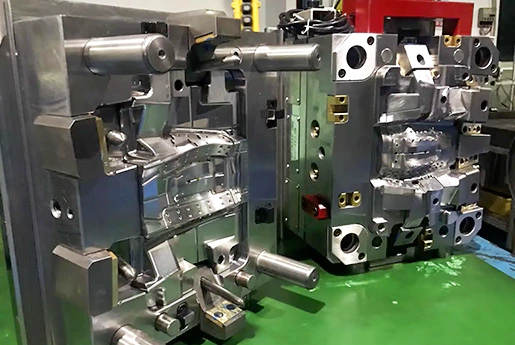

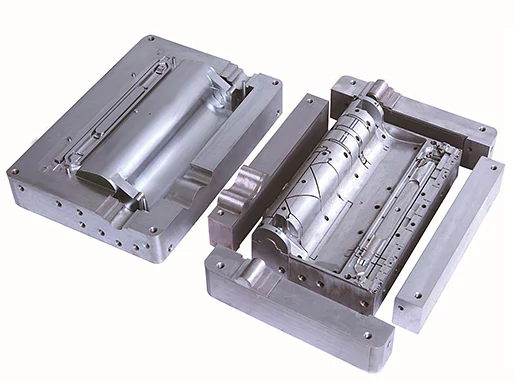

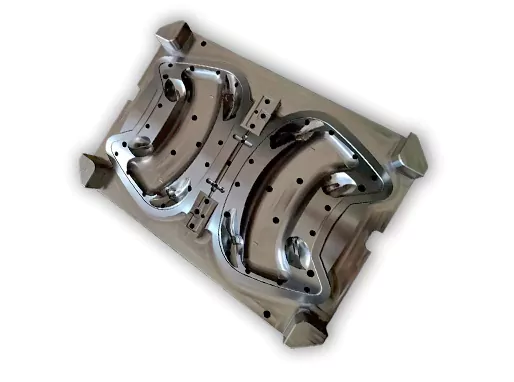

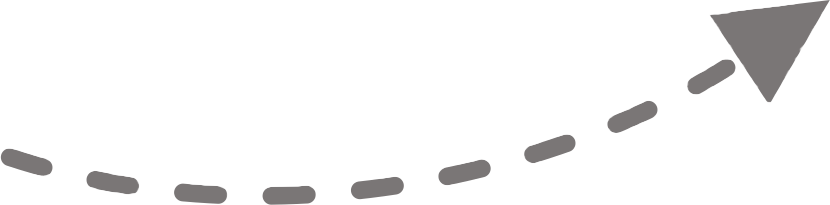

Mold Making Process

Generally speaking, mold production is a complicated process. RY divides mold making into 12 steps.

Drawings Receiving

DFM Check

Materials Preparation

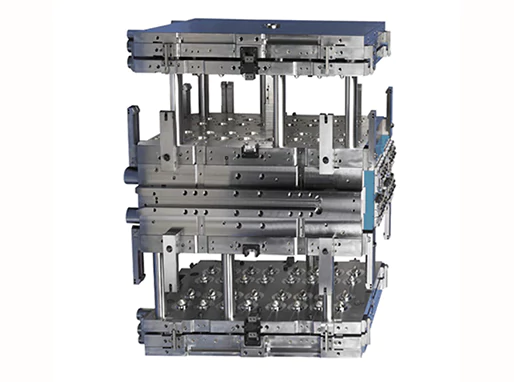

EDM Machining

Wirecut Machining

CNC Machining

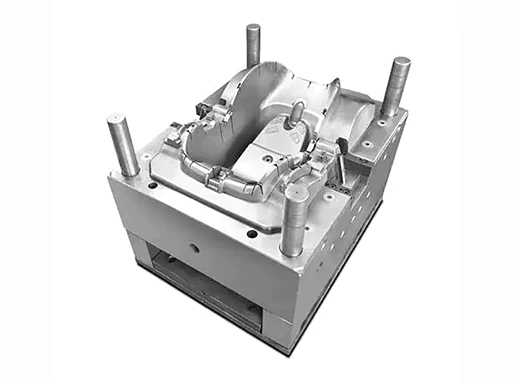

Mold Fitting

Core Fitting

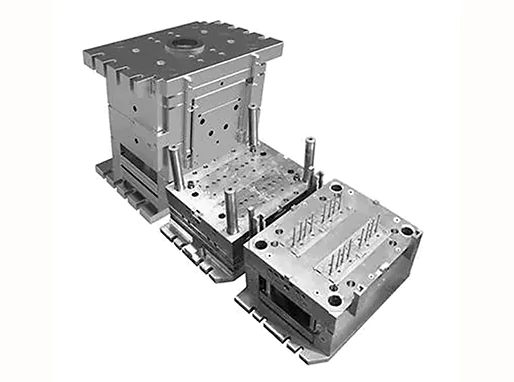

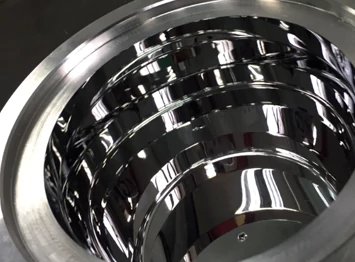

Mold Polishing

Mold Fabrication

Mold Trial

Customer Confirm