CNC machining services in Westminster , England

Our rapid prototyping service, in Westminster , England makes quality components for your needs.

Our rapid prototyping service, in Westminster , England makes quality components for your needs.

Welcome to RuiYi, your premier rapid prototyping service provider in Westminster. With expertise in CNC machining prototyping, sheet metal prototyping, and more, we are dedicated to helping you bring your ideas to life quickly and efficiently. Our team of skilled technicians and engineers is committed to delivering high-quality prototypes that meet your specifications and exceed your expectations. Whether you need a single prototype or a large batch production, we have the capabilities and the experience to handle any project. Contact us today to learn more about how RuiYi can help you with all your rapid prototyping needs in Westminster.

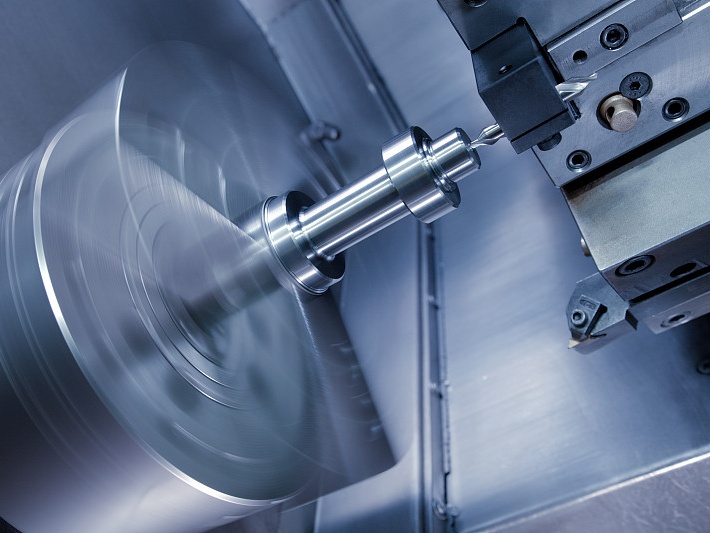

CNC milling utilizes multi-axis capabilities, including 3, 4, and 5-axis machining, to achieve precise and intricate shapes from metal or plastic blocks, efficiently crafting intricate components with unparalleled accuracy.

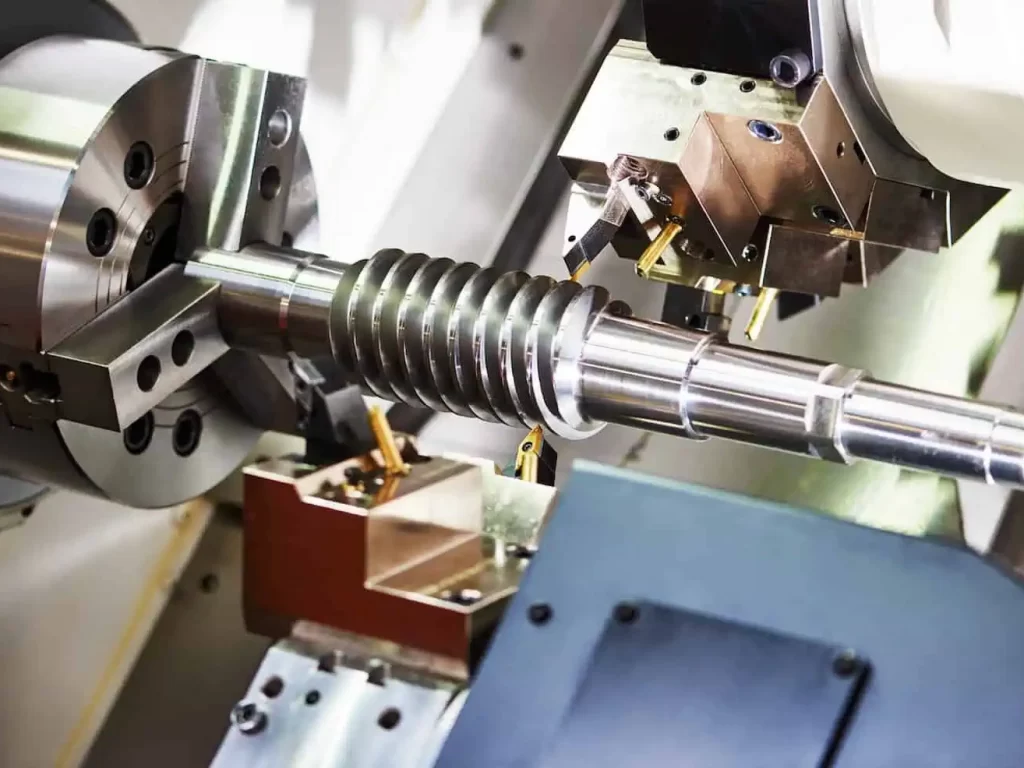

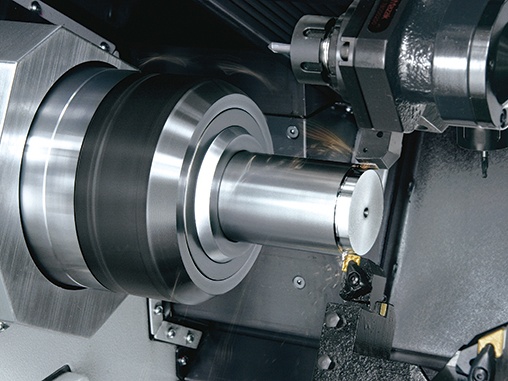

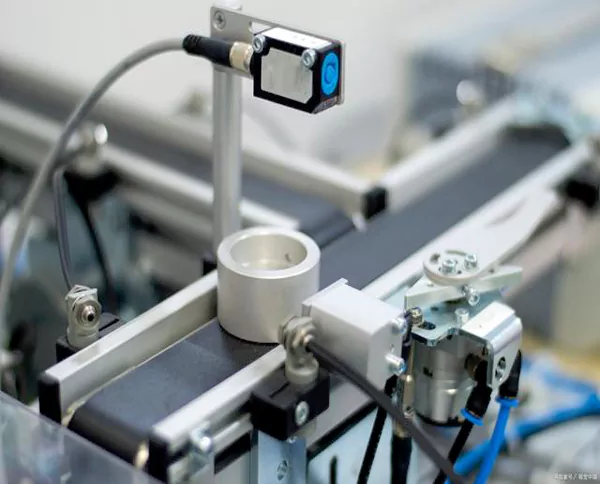

CNC turning uses CNC lathes and turning centers to shape metal rob stock, focusing primarily on cylindrical turned parts. Ensure components achieve consistent dimensions and smooth finishes.

A single-point cutting tool is advanced linearly, moving in a straight path alongside the rotational axis, within the confines of the preexisting hole's inner diameter.

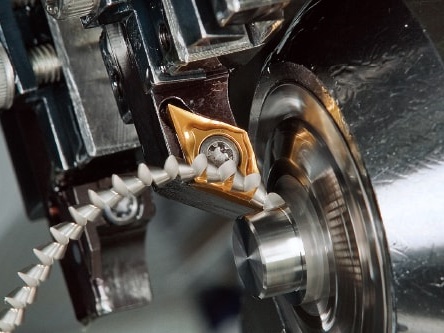

Grooving, a form of CNC turning operation, entails the creation of a slender recess within the workpiece through the application of a specifically designed tool.

Parting is a manufacturing process that requires the use of a gouging technique to completely separate a section from the original workpiece.

This specific CNC turning method simplifies the process of forming grooves in workpieces, allowing for effortless screwing into other components.

This procedure involves intricately shaping the workpiece into a serrated design, aimed at improving the gripping ability of materials that necessitate heightened traction.

Taper turning is a machining process where a cylindrical workpiece is shaped by gradually reducing its diameter along its length, creating a tapered form.

Through programmed means, a form is sculpted around a fixed axis, steadily reducing the diameter to create a perfect spherical shape.

The machining process ensures uniform diameter reduction, preserving consistency throughout to prevent any deviations.

Are you considering using CNC machining services in Westminster, England but have some questions? Here are 10 common Q&A to help guide you through the process:

A: CNC machining is a manufacturing process where pre-programmed computer software dictates the movement of machinery and tools. It can produce a wide range of customized parts and products with high precision.

A: Some benefits of CNC machining services include increased efficiency, higher accuracy, quicker turnaround times, and the ability to work with a variety of materials.

A: You can start by researching local companies, reading reviews, asking for recommendations, and evaluating their experience and capabilities.

A: CNC machining can work with a wide range of materials, including metals, plastics, wood, and composites.

A: The cost of CNC machining services can vary depending on factors such as material, complexity of the design, quantity, and turnaround time.

A: The turnaround time for CNC machining services can vary depending on the complexity of the project and the workload of the machining shop.

A: Yes, CNC machining services are well-equipped to handle custom or complex designs with high precision and accuracy.

A: Yes, many CNC machining services in Westminster, England offer prototyping services to help clients test and refine their designs before full-scale production.

A: You can ensure quality control by working closely with the machining shop, providing detailed specifications, conducting regular inspections, and requesting test samples.

A: Industries such as aerospace, automotive, medical, electronics, and telecommunications can benefit greatly from the precision and versatility of CNC machining services.

By familiarizing yourself with these common Q&A about CNC machining services in Westminster, England, you can make informed decisions when choosing a machining shop for your projects. Remember to consider factors such as experience, capabilities, quality control measures, and turnaround times to ensure a successful partnership.