Rapid prototyping services in Concord , California

Our rapid prototyping service, in Concord , California makes quality components for your needs.

Our rapid prototyping service, in Concord , California makes quality components for your needs.

We proudly offer Rapid Prototyping Services in Concord, California. Utilizing cutting-edge CAD software and state-of-the-art 3D printing technology, we transform your innovative designs into tangible prototypes with remarkable precision and speed. Our services enable quick design validation and functional testing, helping you to accelerate product development and reduce time-to-market. Whether you’re a startup or an established manufacturer, our expertise ensures high-quality prototypes that meet your specific needs and drive your projects forward. Partner with us in Concord to experience the future of manufacturing today.

| Standards | CNC Milling | CNC Turning |

| Maximum Part Size | 7500×3400×1200mm / 295×133.8×47 in. | 200×500 mm / 7.9×19.7 in. |

| Minimum Part Size | 3.5×3.5 mm / 0.13×0.13 in. | 2×2 mm 0.079×0.079 in. |

| Standard Tolerances | +/- 0.01 mm +/- 0.0004 in. | +/- 0.01 mm +/- 0.0004 in. |

| Dimension | Metals: ISO 2768-m Plastics: ISO 2768-c | |

| Standards | Description |

| Thickness wall | 1.0 mm |

| Layer height | 50 – 300 μm |

| Max. build size | 250 * 250 * 250 mm (SLA), 420 * 500 * 420 mm (SLS) |

| Tolerance | ± 0.5% |

| Dimension | Tolerance |

| Edge to edge, single surface / Edge to hole, single surface / Hole to hole, single surface | +/- 0.005 inch |

| Bend to edge / hole, single surface | +/- 0.010 inch |

| Edge to feature, multiple surface / Over formed part, multiple surface | +/- 0.030 inch |

| Angle | +/- 1° |

Vacuum casting, also known as silicone vacuum casting or polyurethane vacuum casting, is a rapid prototyping and low-volume manufacturing process used to create high-quality plastic parts.

| Standard | Description |

| Maximum build size | +/- 0.025 mm (+/- 0.001 inch) |

| Standard lead time | Up to 20 parts in 15 days or less |

| Accuracy | ±0.05 mm |

| Layer thickness | 1.5mm – 2.5mm |

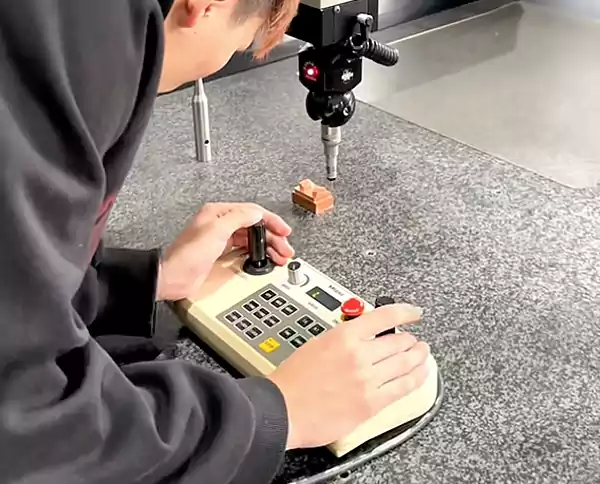

Upload your design to our quoting platform to receive instant, automated quotes along with a complimentary design analysis for your prototypes and production parts.

A design for manufacturability analysis will be completed for you within a few hours.

Once you place your order, we initiate the manufacturing process. Additionally, our digital platform provides real-time updates on the production stage.

After passing quality inspections, the parts are carefully packed for delivery. You can rest assured with our 30-day quality guarantee.

Allows manufacturers to create physical models of a product design to validate its form, fit, and function.

Enables quick iterations and modifications of a product design based on feedback and testing.

Creates prototypes that can be tested under real-world conditions to evaluate performance, durability, and functionality.

Facilitates the creation of custom and complex parts that might be difficult or impossible to using traditional manufacturing methods.

Creates prototypes of tools, jigs, and fixtures that are used in the manufacturing process to produce and assemble products.

Produces prototypes that can be used for market testing, customer feedback, and pre-production marketing.

Rapid prototyping is a process that quickly creates physical models from digital designs using 3D printing and other advanced manufacturing technologies.

We offer a variety of materials, including plastics, metals, and composites, to suit different project requirements and performance needs.

Depending on the complexity and size of the design, prototypes can be delivered within a few days to a week.

We accept a wide range of file formats, including STL, OBJ, STEP, and IGES, ensuring compatibility with most CAD software.

Yes, our team can assist with design adjustments to optimize your prototype for better performance and manufacturability.

Our equipment can handle prototypes up to [insert dimensions], allowing us to accommodate a variety of project sizes.

We offer both functional and visual prototypes, depending on your needs. Functional prototypes can be used for testing and validation, while visual models are ideal for presentations and demonstrations.

We employ rigorous quality control measures, including precise calibration of our 3D printers and thorough inspection of each prototype.

Yes, we provide a range of post-processing services, such as sanding, painting, and assembly, to enhance the final appearance and functionality of your prototype.

Simply contact us with your project details and design files, and our team will guide you through the process from start to finish, ensuring a smooth and efficient prototyping experience.