Rapid prototyping services in Hesperia , California

Our rapid prototyping service, in Hesperia , California makes quality components for your needs.

Our rapid prototyping service, in Hesperia , California makes quality components for your needs.

Welcome to our Rapid Prototyping Services in Hesperia, California! we specialize in transforming your innovative ideas into reality with precision and speed. Our cutting-edge technology and expert team are dedicated to delivering high-quality prototypes tailored to your specific needs. Whether you require 3D printing, CNC machining, or any other prototyping method, we ensure quick turnaround times and exceptional accuracy. Partner with us to bring your concepts to life and drive your projects forward. Contact us today to get started.

| Standards | CNC Milling | CNC Turning |

| Maximum Part Size | 7500×3400×1200mm / 295×133.8×47 in. | 200×500 mm / 7.9×19.7 in. |

| Minimum Part Size | 3.5×3.5 mm / 0.13×0.13 in. | 2×2 mm 0.079×0.079 in. |

| Standard Tolerances | +/- 0.01 mm +/- 0.0004 in. | +/- 0.01 mm +/- 0.0004 in. |

| Dimension | Metals: ISO 2768-m Plastics: ISO 2768-c | |

| Standards | Description |

| Thickness wall | 1.0 mm |

| Layer height | 50 – 300 μm |

| Max. build size | 250 * 250 * 250 mm (SLA), 420 * 500 * 420 mm (SLS) |

| Tolerance | ± 0.5% |

| Dimension | Tolerance |

| Edge to edge, single surface / Edge to hole, single surface / Hole to hole, single surface | +/- 0.005 inch |

| Bend to edge / hole, single surface | +/- 0.010 inch |

| Edge to feature, multiple surface / Over formed part, multiple surface | +/- 0.030 inch |

| Angle | +/- 1° |

Vacuum casting, also known as silicone vacuum casting or polyurethane vacuum casting, is a rapid prototyping and low-volume manufacturing process used to create high-quality plastic parts.

| Standard | Description |

| Maximum build size | +/- 0.025 mm (+/- 0.001 inch) |

| Standard lead time | Up to 20 parts in 15 days or less |

| Accuracy | ±0.05 mm |

| Layer thickness | 1.5mm – 2.5mm |

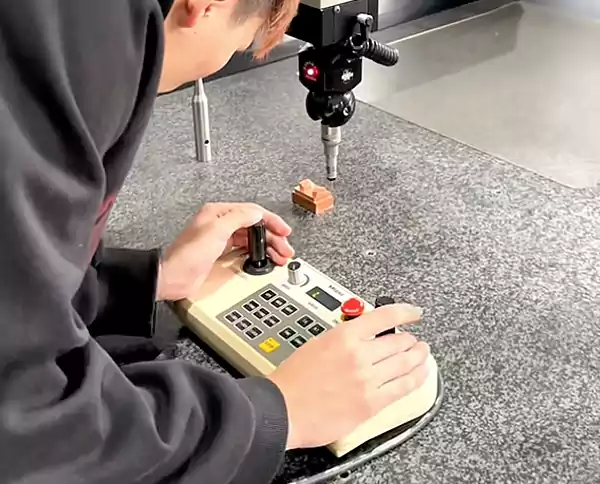

Upload your design to our quoting platform to receive instant, automated quotes along with a complimentary design analysis for your prototypes and production parts.

A design for manufacturability analysis will be completed for you within a few hours.

Once you place your order, we initiate the manufacturing process. Additionally, our digital platform provides real-time updates on the production stage.

After passing quality inspections, the parts are carefully packed for delivery. You can rest assured with our 30-day quality guarantee.

Allows manufacturers to create physical models of a product design to validate its form, fit, and function.

Enables quick iterations and modifications of a product design based on feedback and testing.

Creates prototypes that can be tested under real-world conditions to evaluate performance, durability, and functionality.

Facilitates the creation of custom and complex parts that might be difficult or impossible to using traditional manufacturing methods.

Creates prototypes of tools, jigs, and fixtures that are used in the manufacturing process to produce and assemble products.

Produces prototypes that can be used for market testing, customer feedback, and pre-production marketing.

Rapid prototyping is a process used to quickly create scale models of a physical part or assembly using three-dimensional computer-aided design (CAD) data. It is an essential step in the product development cycle.

We offer a range of services including 3D printing, CNC machining, injection molding, and vacuum casting. Each method is chosen based on the specific needs of your project.

The turnaround time can vary depending on the complexity and size of the prototype. Typically, our rapid prototyping services can deliver results within a few days to a week.

We work with a variety of materials including plastics, metals, and composites. Our team will help you choose the best material for your specific application.

Yes, we can create both visual and functional prototypes. Functional prototypes are designed to closely mimic the final product in terms of performance and functionality.

We serve a wide range of industries including automotive, aerospace, medical, consumer goods, and electronics, among others.

Our prototypes are highly accurate, with tolerances typically within ±0.1mm, depending on the process and material used. We ensure high precision to meet your exact specifications.

Absolutely. Our experienced team can provide support throughout the design and development process, from initial concept to final product, ensuring your prototype meets all your requirements.

The cost varies based on factors such as the complexity of the design, the materials used, and the chosen prototyping method. Contact us for a detailed quote tailored to your project.

Getting started is easy. Simply contact us through our website or call our Hesperia office to discuss your project needs. We’ll guide you through the process and provide you with a comprehensive plan to bring your ideas to life.