Sheet Metal Fabrication in Lansing, Michigan

Our sheet metal fabrication, in Lansing , Michigan, makes quality components for your needs.

Our sheet metal fabrication, in Lansing , Michigan, makes quality components for your needs.

As a leading manufacturing service provider, RuiYi specializes in a wide range of rapid prototyping services to meet the diverse needs of our clients. Our expertise includes sheet metal prototyping, CNC machining prototyping, vacuum casting prototyping, 3D printing prototyping, and more. At RuiYi, we understand the importance of high-quality prototypes in the product development process. Whether you are looking to test the functionality of a new design, validate a concept, or showcase a physical model to potential investors, our team of skilled professionals is dedicated to delivering superior results.

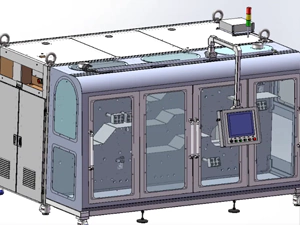

With our sheet metal fabrication capabilities, we are able to produce precise and durable prototypes that accurately reflect your design specifications. Our state-of-the-art equipment and advanced techniques ensure consistent quality and efficient turnaround times. Whether you require a single prototype or a small batch of parts, we are equipped to handle projects of any size and complexity.

At RuiYi, we prioritize customer satisfaction and strive to exceed expectations with every project we undertake. Our commitment to excellence, attention to detail, and dedication to innovation set us apart as a trusted partner for all your rapid prototyping needs. Contact us today to learn more about how RuiYi can help bring your designs to life with our comprehensive range of prototyping services.

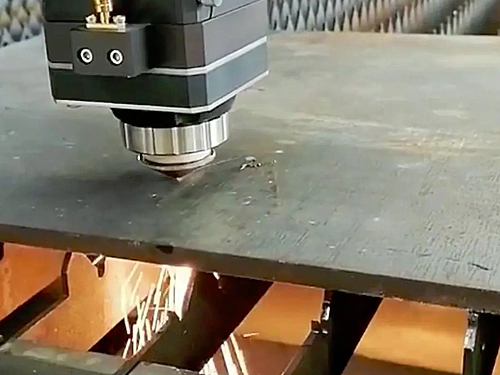

Laser cutting employs a concentrated laser beam to slice, inscribe, or carve materials by either vaporizing or melting them. As a result, it achieves precise edges and designs that align with the designer's requirements.

Sheet metal is a cost-saving option for making panels, boxes, and cases for various products. We create enclosures in all styles with plasma cutting, like rackmounts, "U" & "L" shapes, consoles, and consolets.

The shaping of a thin metal sheet into various forms is accomplished through the application of force during the bending process. Moreover, the metal's thickness can vary, allowing for flexibility in design and functionality.

Design and create a parts drawing for sheet metal components, referred to as a three-dimensional view, which serves the purpose of illustrating the structure of sheet metal parts through drawings.

Key sheet metal cutting methods:

a. Shearing & punching for size & shape.

b. Punch blanking for efficiency.

c. NC blanking with CNC.

d. Laser cutting.

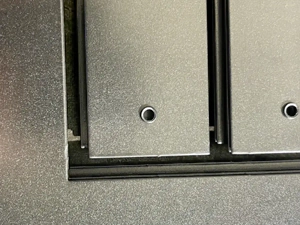

Flanging (not drilling) involves enlarging a small hole and tapping it for strength and anti-slip. It's suitable for thin plates. Thicker plates can be tapped directly without flanging.

Punch processing includes punching, corner cutting, blanking, convex bulging, tearing, and drilling, requiring corresponding molds. Convex bulges need convex molds, and tearing needs tear molds.

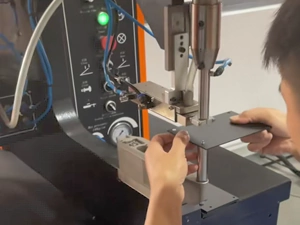

Our factory frequently employs pressure riveting for studs, nuts, screws, etc., utilizing punches or hydraulic machines for secure attachment to sheet metal parts, achieving superior quality and strength.

Bending entails folding 2D parts into 3D using a folding machine and molds, following a sequence. The key is to bend first without blocking subsequent cuts, preventing interference and back-folding.

Surface treatments include phosphate, electroplated zinc, chromate, baking paint, and oxidation. Choices depend on material (cold-rolled, aluminum) and customer needs, enhancing protection and paint adhesion.

Assembly combines parts into a complete item, requiring material protection to avoid scratches that could cause rework, wasting time and raising costs. Special attention to material protection is essential.

Acquire premium sheet metal prototypes in just 3 business days. This swift and budget-friendly service, devoid of any minimum order limits, facilitates efficient design verification and cuts costs, enabling smoother product revisions.

Perfect for transitioning to full-scale production or accommodating small-batch needs, our flexible low-volume sheet metal service adapts to your schedule, guaranteeing timely delivery with outstanding quality consistency.

Our comprehensive, cutting-edge service offers swift and accurate high-volume sheet metal manufacturing, encompassing finishing and assembly, adhering to your specifications while reducing both time and costs for bulk orders.

Lightweight with a metallic white luster, the material is prone to surface scratching. Therefore, a PVC protective film is often applied to protect it. It offers excellent durability and strong corrosion resistance.

Common treatments include sandblasting, wire drawing, or polishing, typically followed by anodic or chromate oxidation for enhanced performance and aesthetics.

Copper: Known for its excellent electrical and thermal conductivity, copper also offers good processability, strong fusion properties, corrosion resistance, and weatherability. With its metallic red luster, it is ideal for use in the electrical and chemical industries.

Brass: Brass is highly ductile and easy to process, making it ideal for plating applications. It is commonly used in manufacturing wiring equipment, instrument panels, bullet casings, and more.

The general tolerance of the material thickness +0, -0.08, that is, the plate thickness of 2.0mm measured may only be 1.92mm.

The measurement of material thickness should be used a micrometer (micrometer), do not use cursor calipers.

In Lansing, Michigan, there are a variety of sheet metal fabrication services available to suit different needs. Some of the common types of sheet metal fabrication that are affordably offered in Lansing include laser cutting, punching, bending, welding, and assembly. Laser cutting is a precise and efficient method that uses a high-powered laser to cut materials with intricate designs. Punching is another method used to create holes or shapes in sheet metal. Bending is essential for creating different angles and shapes in the metal. Welding is a crucial process that involves joining pieces of metal together. Finally, assembly involves putting together the different fabricated pieces to create the final product. These services are provided by skilled professionals in Lansing who have the expertise and equipment to handle a wide range of sheet metal fabrication projects with precision and quality.

The speed at which you will receive the fabricated metal item you ordered in Lansing, Michigan, will depend on a few factors. First, consider the current workload of the fabrication company you ordered from. If they are experiencing a high volume of orders, it may take longer to fulfill yours. Additionally, the complexity of the item you ordered will also play a role in the production time. Simple items may be produced and shipped quicker than more intricate pieces. Finally, the shipping method you chose at checkout will impact the delivery time. Expedited shipping options will obviously arrive faster than standard shipping methods. Overall, most fabrication companies aim to process orders as quickly as possible without sacrificing quality. It is worth contacting the company directly for a more specific estimate on when you can expect to receive your metal item.

Yes, we offer design services for patrons in Lansing, Michigan. Our team of experienced designers can help bring your vision to life by creating customized designs tailored to your specific needs and preferences. Whether you are looking to refresh the look of your home, office, or business, we can provide you with creative solutions that will enhance the aesthetic appeal of your space. From interior design to graphic design, we have the expertise to handle a wide range of projects and deliver high-quality results that exceed your expectations. Our commitment to customer satisfaction ensures that we work closely with you throughout the design process to ensure that your requirements are met and that the final product reflects your personal style and taste. Contact us today to learn more about our design services and how we can help transform your space in Lansing, Michigan.

Yes, high-volume production can certainly be undertaken in Lansing, Michigan. With its strategic location, skilled workforce, and access to various resources, Lansing provides an excellent environment for businesses looking to scale up their production operations. The city’s proximity to major transportation routes, including highways and railways, allows for efficient distribution of goods to markets both within the state and beyond. Additionally, Lansing is home to several universities and technical training centers, which ensure a steady supply of qualified professionals in various fields. Furthermore, the region boasts a diverse industrial base, offering businesses access to a wide range of suppliers and service providers. Overall, Lansing’s business-friendly environment, combined with its supportive infrastructure and skilled labor force, make it a viable location for high-volume production activities.

In our sheet metal fabrication process, quality verification is a critical step to ensure that our products meet the highest standards of precision and durability. Our verification procedure begins with thorough inspections of the raw materials, including sheet metal thickness, dimensions, and surface finish. Throughout the fabrication process, our skilled technicians meticulously monitor each stage to verify compliance with design specifications and quality standards. This includes regular checks for accuracy in cutting, bending, welding, and finishing. Once the fabrication is complete, comprehensive quality control checks are carried out to validate the structural integrity, dimensional accuracy, and surface quality of the final product. We also conduct performance testing to confirm that the product meets the intended functionality and operating requirements. By adhering to a strict quality verification procedure, we can guarantee that our sheet metal fabrication products are of the highest quality, ensuring customer satisfaction and long-lasting reliability.

To initiate with our company’s services in Lansing, Michigan, you can start by visiting our website and exploring the range of services we offer. Once you have identified the specific service that best fits your needs, you can contact our customer service team either through phone or email. Our customer service representatives will be able to provide you with more information about the service, pricing, and any promotional offers that may be available. They will also guide you through the process of setting up an appointment or consultation with our experts in Lansing. Additionally, you can also visit our physical location in Lansing to speak with a representative in person and get a firsthand look at our facilities. We are dedicated to providing top-quality services to our clients and ensuring a smooth and efficient onboarding process.

Thank you for your inquiry about the price of our company’s services in Lansing, Michigan. Our pricing structure is tailored to meet the unique needs of each client, based on the specific services required and the scope of the project. While we cannot provide a one-size-fits-all answer to your question, we can assure you that our rates are competitive and transparent. We believe in providing exceptional value to our clients while maintaining a high standard of quality in our work. Rest assured that our team of experienced professionals will work closely with you to develop a customized solution that fits your budget and exceeds your expectations. For a more detailed quote, we invite you to contact us directly to discuss your project requirements and receive a personalized estimate. Thank you for considering our services, and we look forward to the opportunity to work with you in Lansing, Michigan.