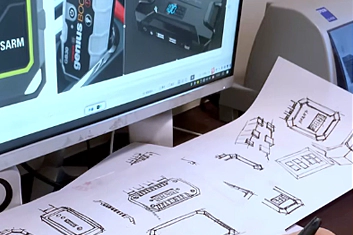

Any time designers, engineers plus businesses take application into consideration, several of them notice prototyping and size production as typically the primary goal blogposts. But there are usually times when low-volume manufacturing is typically the optimal choice for individuals who need modest amounts of finished elements, ranging between a few hundred to hundreds of hundreds.

By utilizing a expert prototyping and production service like Ruiyi model, our customers gain the ability to be able to find the actual sum of parts they desire, whatever the ultimate count might end up being.

At Ruiyi model, we all will be right now there to help you along all the way, from the first product design overview and quotation to quality inspection of your respective newly created elements. In addition to be able to specialising in prototyping and mass creation, we are likewise consultant when it comes to low-volume manufacturing. Contact our own expert team today to get a new free project overview and initial estimate.

If you desire a prototype to verify your design 1st, please review our own rapid prototyping solutions.

What is low volume manufacturing?

Depending on the processes, tools, and materials employed, low-volume manufacturing can range from producing as few as 50 units to as many as 100,000 units. This approach serves as a crucial bridge between rapid prototyping and mass production. It allows companies to test products and markets efficiently through small-batch production methods.

By utilizing low-volume manufacturing, businesses can bring their products to market quickly, respond promptly to design changes, and significantly shorten the manufacturing cycle. This strategy not only enhances flexibility but also reduces time-to-market, enabling companies to stay competitive and agile in a rapidly changing marketplace.

| Low volume production | Bridge Production | Massive Production | |

|---|---|---|---|

| Prefered Machines | Smaller Tool Stock, More Axis | Bigger Tool Stock, More Axis | More Tool Stock, Less Axis |

| Fixtures | Mostly Standard Fixtures | Some Custom Made Fixtures | Custom Made Fixtures |

| Reachable Tolerance | High Precise with large Variance | Precise with some Variance | High Precise with small Variance |

| Price | Very High / Unit | High/Unit | Low/Unit |

| Other Things | Manual work might be needed like hand grinding, polishing, etc. | More Processes can be considered, forging, grinding, lasering, welding, brazing etc. |

Why Choose Small Batches Production?

Cost-effectiveness

Small batch production can reduce initial investment and production costs, especially when companies are testing new products or entering new markets, small batch production can reduce inventory pressure and the risk of overproduction.

Reduce financial pressure

Small batch production can reduce the capital pressure of enterprises. It does not require a large amount of capital to be invested in large-scale production, which helps enterprises manage capital flow more flexibly.

Flexible market response

Small batch production enables companies to respond quickly to market demands and changes. Through small batch production, companies can adjust product designs and features more quickly to adapt to changes in consumer demand.

Product Quality Control

Small batch production makes it easier to conduct quality control and product testing. Problems that arise during the production process can be quickly discovered and corrected to ensure the high quality of the final product.

Reduced waste

Since small batch production involves fewer materials and resources, waste and environmental burden are reduced. Companies can control the production process more precisely and avoid unnecessary material waste.

Customized production

Small batch production is very suitable for the production of customized products. Customers can make specific requirements according to their needs, and enterprises can carry out small batch customized production according to these needs and provide personalized services.

Technology Verification

Small batch production can be used as a means of verifying new technologies and processes. Before large-scale production, companies can test the feasibility and effectiveness of new technologies through small batch production to reduce the risk of large-scale production.

Quick time to market

Small batch production helps new products to be quickly launched. Companies can quickly launch new products through small batch production, seize market opportunities and gain competitive advantages.

Advantages for LVM

Cost-effective

This production method reduces total production lead time and minimizes tooling costs. More importantly, it saves you from unnecessary expenses when design changes are needed.

Design Flexibility and Iterations.

Without expensive tooling or reorganizing complex production techniques. Low-volume production allows for easy validation, engineering, and assessment of the manufacturability of design ideas.

Reduced Errors/Defects

Mass production frequently reveals complexities not detected during the prototyping phase. Low-volume production detects issues early, preventing costly problems in high-volume tooling.

Low Inventory

Low-volume production is ideally suited for just-in-time (JIT) management systems. Unlike mass production, it eliminates the need to maintain extensive inventories of sub-components or replacement parts.

Faster Marketing

Low-volume production methods are an ideal and reliable way to expedite getting your products to market. Additionally, low-volume manufacturing optimizes the supply chain, ensuring that parts are ready for launch within days or weeks rather than months.

Smooth Bridge Production

This production technique provides a progressive pathway to scale up to mass production. It simplifies best practices to ensure cost-efficiency while enhancing product quality as volume gradually increases.

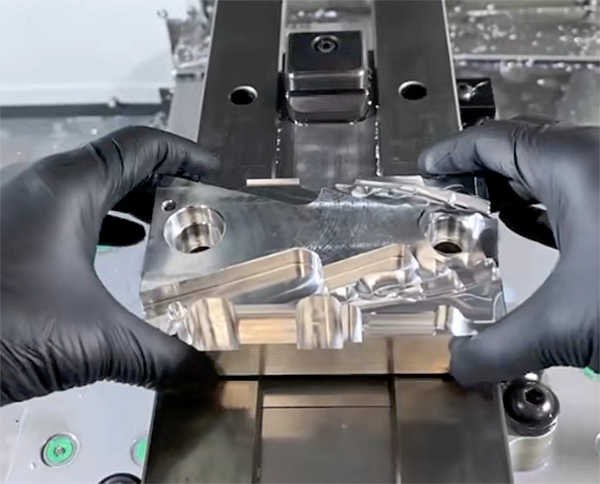

Different Types of Small Batch Processing

Low-volume machining is an important subset of CNC machining services, covering a range of processes, each tailored to meet specific manufacturing needs. Characterized by their precision and adaptability, these methods are fundamental to the manufacture of high-quality components in small batches.

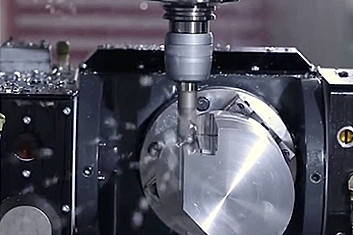

CNC Turning

CNC turning is a basic process in low-volume CNC machining that involves the workpiece rotating while a stationary cutting tool shapes it. This operation is typically performed on a CNC lathe and is essential for the precise manufacture of cylindrical parts. In low-volume production, turning plays a key role due to its efficiency and accuracy.

Custom Components: Suitable for producing custom parts with specific dimensions.

Material Versatility: Effectively processes a wide range of materials, including metals such as aluminum and brass.

Precision Manufacturing: Provides high accuracy for components that require tight tolerances.

Surface Finish: Achieve a superior surface finish, which is essential for both functionality and aesthetics.

CNC Milling

The CNC milling process is a versatile and widely used operation for low-volume machining that involves the removal of material using a rotating cutting tool. CNC milling machines are characterized by their ability to move along multiple axes, enabling the creation of complex shapes and features. This machining process is essential in low-volume machining due to its precision and flexibility.

Complex Geometries: Capable of producing complex shapes and detailed features.

Rapid Prototyping: Ideal for quickly creating prototypes to test designs.

Highly Customizable: Easily adaptable to unique design requirements.

Efficient Production: Saves time, especially for low-volume production.

CNC Drilling

In low-volume machining, CNC drilling involves drilling holes or creating cavities in a workpiece. The process is performed using a CNC drilling machine and is essential for adding functional features such as screw holes or routing channels. The precision and speed of drilling make it a valuable process in low-volume CNC machining.

Accurate Hole Location: Ensures precise positioning of holes, which is essential for the functionality of a component.

Depth Control: Allows for precise depth specification, which is critical for a variety of applications.

Material Compatibility: Effectively processes a range of materials from plastics to hardened metals.

Custom Flexibility: Accommodates different hole sizes and patterns, essential for custom projects.

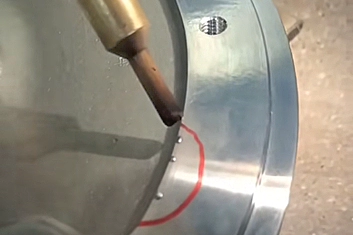

Surface Grinding

Surface grinding is an essential process for achieving fine surface finishes and precise flatness, and is another key component of low-volume CNC machining. This operation uses a rotating grinding wheel to smooth the surface of the workpiece. Precision surface grinders are used to ensure uniformity and accuracy in the final product.

Superior Surface Finish: Essential for projects where surface smoothness is critical.

Achieve Tight Tolerances: Achieve high precision in flatness and thickness.

Material Versatility: Works with a wide range of materials from metals to plastics.

Custom Tools and Fixtures: Allows for the creation of specialized tools and fixtures with precise surface requirements.

Multi-Axis Machining

Multi-axis machining, which includes 3-, 4-, and 5-axis machining, represents the pinnacle of versatility and precision in low-volume CNC machining. These machines are able to move the tool or workpiece in multiple directions simultaneously, enabling the creation of complex geometries with high precision.

Complex 3D Geometries: Ideal for parts with intricate designs and contours that require multi-dimensional machining.

Reduced Setup Time: Multi-axis capabilities minimize the need for multiple setups, increasing efficiency.

High Precision and Consistency: Ensure consistent quality for low-volume batches, which is critical in industries such as aerospace and medical devices.

Optimized Material Utilization: Efficiently utilize materials, reduce waste, and lower unit costs.

Electrical Discharge Machining

Electrical Discharge Machining (EDM), which includes both EDM and Wire EDM, is a process designed for low-volume production. EDM uses electrical sparks to erode materials and is ideal for machining hard metals and intricate designs. The process requires a machine with an electrode (EDM) or fine wire (Wire EDM) to achieve precise cuts and shapes.

Complex Shapes and Fine Details: Ideal for producing complex designs that are challenging with traditional machining methods.

Hard Material Machining: Efficiently processes materials that are difficult for other machining processes, such as titanium and hardened steel.

Minimal Surface Impact: Maintains the integrity of the workpiece, ensuring an excellent surface finish.

Precision Slots and Pockets: Ideal for creating precise slots, pockets, and complex 3D shapes.

Common Processing Used In LVM

CNC machining, which removes material by rotating a tool and a fixed part (milling) or a rotating part with a fixed tool (lathe). CNC mills and lathes can have multiple axes, which allows them to manage more complex designs.

CNC machining can mold parts in plastics, soft metals, hard metals (industrial machines), wood, acrylic, stone, glass and composites. They are well suited for producing custom or low-volume end-use parts, structural parts, and molds for a wide range of industries.

CNC tools are more complex to set up and operate than additive manufacturing tools, and certain materials and designs may require special tooling, handling, positioning and machining. This makes one-off parts more costly and more suited to small batch production than additive processes.

Machining is well suited for low volume manufacturing applications that require tight tolerances and difficult to mold geometries. cnc machining has low to moderate setup costs and can produce high quality parts in a wide range of materials with short lead times.

Advantages of CNC machining for low-volume production include:

High Precision: CNC machining offers exceptional precision and accuracy, allowing for the production of complex geometries and tight tolerances, crucial for creating high-quality parts.

Versatility: It can work with a wide range of materials, including metals, plastics, wood, and composites, making it suitable for a variety of applications and industries.

Scalability: CNC machining is scalable, meaning it can easily adjust production quantities based on demand, making it suitable for both low and high-volume production runs.

Complexity: It can produce parts with complex geometries, intricate features, and fine details, allowing for the creation of highly customized and specialized components.

Quality Control: CNC machining offers consistent and repeatable results, ensuring high-quality parts with minimal variation, which is essential for maintaining product quality standards.

In recent years, 3D printing has become very mature in prototyping and product development. Now, this mature technology is being widely used in the manufacturing industry.

During the product development process, we can use the flexibility of 3D printing for our customers to print a variety of products, tools, such as prototypes, jigs, fixtures and other manufacturing aids, and even rapid molds, such as molds for injection molding or thermoforming.

The most common processes for producing plastic parts being: selective laser sintering (SLS), stereolithography (SLA), and fused deposition modeling (FDM).

Advantages of 3D printing include:

Complex Geometry: It can create intricate and complex shapes that are difficult or impossible to achieve with traditional manufacturing methods, enabling innovative designs and lightweight structures.

Reduced Waste: Unlike subtractive manufacturing methods, which generate significant waste, 3D printing is an additive process that only uses the material needed to build the part, minimizing waste.

Design Freedom: 3D printing offers unparalleled design freedom, allowing designers to create complex geometries, internal structures, and lightweight components without the constraints of traditional manufacturing methods.

Accessibility: The increasing availability and affordability of 3D printing technology have made it more accessible to individuals, small businesses, and industries alike, democratizing manufacturing processes.

Sustainability: 3D printing can contribute to sustainability efforts by reducing material waste, energy consumption, and carbon emissions compared to traditional manufacturing methods.

Sheet metal fabrication entails shaping metal sheets or alloys using processes like cutting, blending, punching, stamping, and finishing. While high-volume production initially incurs significant installation costs and cycle times, low-volume sheet metal fabrication minimizes setup time, allowing for quicker job changeovers.

Advantages of low-volume production include:

Flexibility: Low-volume production allows for greater flexibility in responding to market demand fluctuations, customization requests, and design changes.

Rapid Prototyping: It enables rapid prototyping and iteration, facilitating quick testing of new product designs and features before committing to large-scale production.

Customization: It offers the ability to produce customized or niche products that may not have sufficient demand for mass production, catering to specific customer needs.

Risk Mitigation: By avoiding the commitment to large-scale production, low-volume production mitigates the risk of overproduction and unsold inventory, ensuring better financial stability.

Vacuum casting, also known as silicone vacuum casting or polyurethane vacuum casting, is a rapid prototyping and low-volume manufacturing process used to create high-quality plastic parts. Here are its advantages:

Advantages:

High-Quality Parts: Vacuum casting produces parts with excellent surface finish and fine details, making them suitable for visual prototypes, functional testing, and even low-volume production.

Wide Material Selection: It offers a wide range of material options, including various polyurethanes, silicones, and other resins, allowing for flexibility in meeting different requirements such as flexibility, transparency, or heat resistance.

Cost-Effective for Low Volumes: Vacuum casting is more cost-effective than traditional injection molding for low to medium volumes of parts (typically ranging from a few dozen to a few hundred), as it requires less expensive tooling and setup.

Short Lead Times: The process is relatively fast, with lead times ranging from a few days to a couple of weeks, depending on the complexity of the parts and the workload of the service provider.

Partially manufactured products