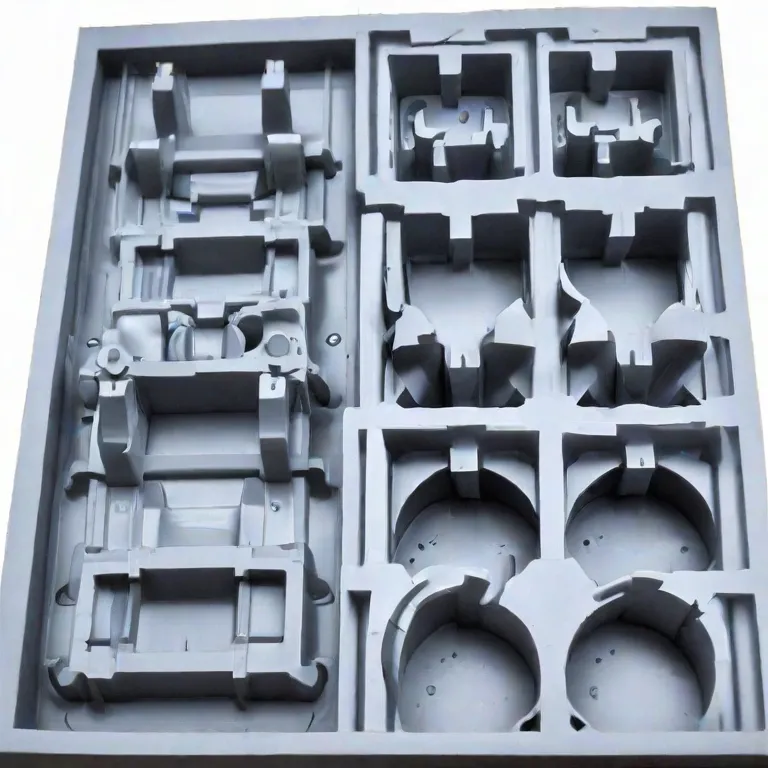

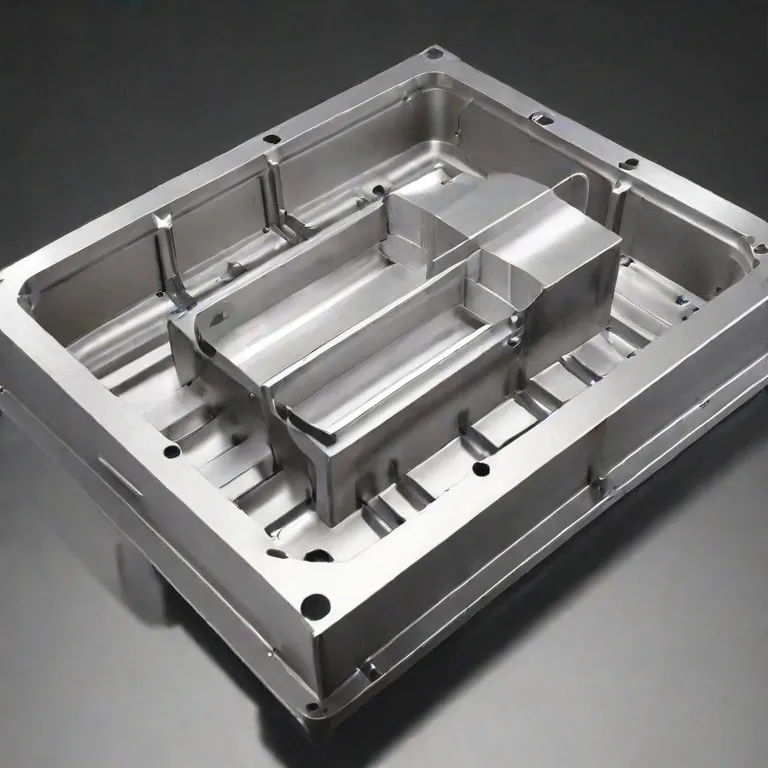

Upon completion of the rapid tooling phase, your product advances to mass production, where our production tooling services prove invaluable. Our services encompass the creation of various molds, including those for injection molding, blow molding, extrusion, die casting, forging, stamping, and other specialized molding techniques.

Ours production tooling service has been cultivated in this industry for many years, representing the level of Chinese industrial manufacturing, and has been widely praised by our customers.