Hello, welcome to follow the Ruiyi model. What are the factors that affect the accuracy of CNC machining? What is it? Let us take a look at the following reasons:

Position error refers to the deviation between actual and ideal positions of surfaces, axes, or symmetry planes, such as in perpendicularity and symmetry.

Machine tool error: The machine tool error generally refers to the dead angle error.

Position errors mainly result from transmission clearance, elastic deformation, and friction during machining.

Open-loop systems greatly affect position accuracy, while closed-loop systems rely mainly on displacement detection.

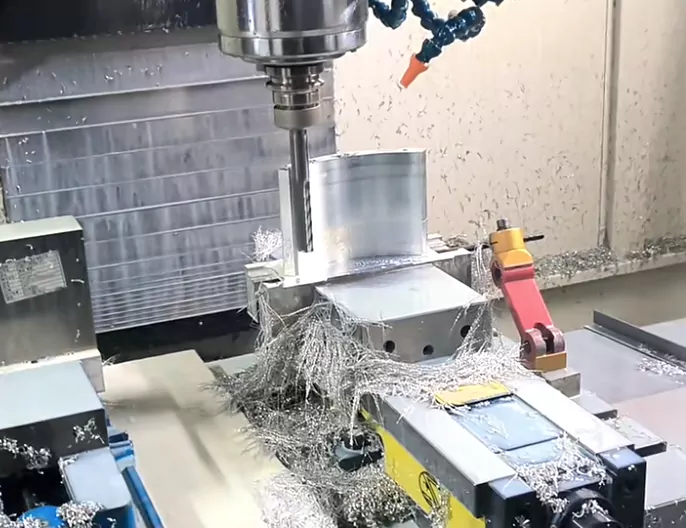

Geometrical errors in CNC machining cause machining accuracy errors.

External forces, heat generated during machining, and other factors affect the geometric accuracy of the machine tool in CNC machining.

Consequently, the geometric deformation of the processed workpiece causes geometric errors in the machine tool.

From a theoretical analysis, the reasons for the geometric errors of CNC machine tools are internal and external factors.

Geometric errors often stem from internal factors like uneven tables, misaligned guide rails, and inaccurate tooling.

External factors mainly refer to the geometric errors caused by the external environment and thermal deformation during processing.

During cutting, thermal expansion, contraction, and deformation of tools or parts affect machining accuracy.

Cumulative error: Long-term data shows machining accuracy errors stem from the positioning of the machine tool.

In CNC machine tools, the position of the machine tool has a great influence on machining accuracy.

In terms of structure, the machining error of CNC machine tools mainly comes from positioning accuracy, and the machine tool feed system is its main link.

CNC machine tool feed system generally consists of two parts: mechanical transmission and electrical control.

In the mechanism design, the positioning accuracy mainly depends on the mechanical transmission system.

In a closed-loop system, the machine tool uses positioning detection to prevent position deviation of key feed components like the ball screw.

Open-loop systems, affected by many factors and complex conditions, cannot be accurately monitored, reducing machining accuracy.

The above explains the factors that affect processing accuracy. I hope this information is helpful to you.

If you’re interested in learning more about this topic, please read the full article.

Contact our company’s CTO Richard

Whatsapp/Skype: +15625110455

FAQ:

Position error refers to the deviation between the actual and ideal positions of a part’s surface, axis, or symmetry plane, such as in perpendicularity or symmetry errors.

Position errors are mainly caused by transmission clearance, elastic deformation, and friction during machining operations.

Machine tool errors, such as dead angle errors or structural inaccuracies, directly influence the precision of the final workpiece.

Open-loop systems lack feedback control, making them more prone to accuracy loss, while closed-loop systems use displacement detection to correct position deviations in real time.

Geometric errors occur when the shape or alignment of machine components—such as guide rails or tables—deviate from ideal geometry, causing machining inaccuracies.

External forces, environmental temperature changes, and heat generated during cutting can cause thermal deformation of the machine or workpiece, reducing geometric accuracy.

Internal factors include uneven machine tables, misaligned guide rails, and inaccuracies in tooling or assembly that impact machining precision.

During cutting, both the tool and workpiece can expand or contract due to heat, leading to dimensional changes and reduced machining precision.

Cumulative error refers to the gradual increase in positioning and alignment inaccuracies over time due to wear, backlash, or repeated thermal effects in the machine tool.

Improving positioning accuracy involves optimizing the mechanical transmission system, maintaining the feed system, and using closed-loop feedback to detect and correct deviations.