CNC machining is a key method for achieving high-precision processing.

However, even when using high-precision CNC equipment, the skill level of the machinist still limits the final processing accuracy.

Machinist operations include clamping, tool alignment, and parameter setup; deviations in any stage affect final quality.

During workpiece clamping and positioning, the machinist must consider factors such as workpiece deformation control, reference point selection, and clamping force;

during tool alignment, the machinist must address issues such as reference surface selection, tool alignment system choice, and compensation strategies.

process parameter settings require comprehensive consideration of material properties, tool performance, and machining requirements.

This article studies machinist impact on accuracy, sets standards, and explores methods to improve CNC machining quality.

Analysis of the Mechanism by Which Machinist Operations Affect CNC Machining Precision

As a key step in CNC machining, machinist operations directly affect machining accuracy.

During workpiece clamping, fixture deformation significantly affects machining precision.

Excessive or insufficient clamping causes deformation or vibration, leading to poor surface roughness.

The workpiece alignment and positioning process involves multiple factors such as the selection of reference surfaces and alignment methods.

Any deviation in alignment will affect the precision of all subsequent machined surfaces.

Tool setting is crucial; traditional methods risk subjective errors, while digital systems face probe wear issues.

Tool wear during machining also affects machining accuracy, and cutting parameters control the tool wear rate.

Therefore, it is necessary to balance feed rate and spindle speed while ensuring efficiency.

Uneven material hardness and internal stress distribution in the workpiece can cause machining deformation, particularly in large-sized thin-walled parts.

Temperature changes and vibrations harm machining accuracy, requiring protective measures to stabilize the environment.

These factors interact and influence each other, forming a complex system.

A thorough analysis of these influencing mechanisms can lay the foundation for the subsequent development of precision control measures.

Precision Control Techniques for Machinist Operations

Workpiece Clamping and Positioning Control Techniques

Workpiece clamping and positioning accuracy directly affects CNC machining quality.

Develop corresponding clamping schemes for workpieces of different shapes.

Square workpieces should use the three-sided positioning method, while cylindrical workpieces should use V-block positioning.

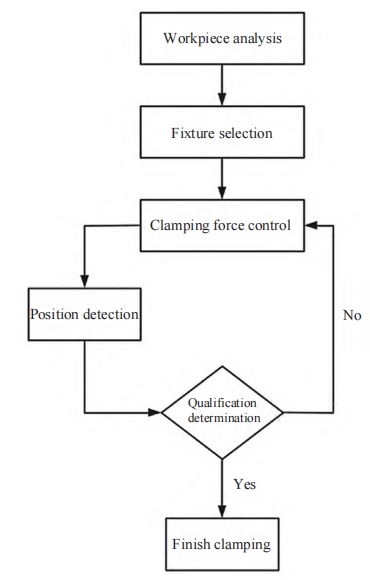

Figure 1 shows the workpiece clamping and positioning control process.

Clamping force control must consider the material properties of the workpiece.

Cast iron workpieces can withstand higher forces, so operators can appropriately increase the clamping force;

aluminum alloy workpieces are sensitive to deformation, so operators should use a smaller clamping force.

Select appropriate fixtures based on the workpiece’s dimensional characteristics.

Precision vise clamps are suitable for small workpieces, while hydraulic fixtures provide greater stability for large workpieces.

Operators should adopt a multi-point support method for thin-walled parts to reduce deformation risks.

The clamping surface must have high flatness and low surface roughness; grinding treatment of the clamping surface may be necessary.

The selection of locating benchmarks follows the principle of the maximum process benchmark to ensure locating accuracy.

Manufacturers make locating elements from high-precision tungsten carbide material to minimize wear during use.

Operators use a torque wrench during actual clamping to precisely control the tightening torque, avoiding uneven clamping force caused by human factors.

Engineers optimize custom fixtures for special parts via finite element analysis to ensure sufficient stiffness.

Operators use a dial indicator after clamping to check the runout of the part and ensure that the clamping accuracy meets the requirements.

Tool Presetting and Tool Alignment Precision Control Technology

Tool presetting plays a decisive role in ensuring machining precision.

Operators perform offline presetting using a tool presetter to measure the tool length dimension compensation value.

During presetting, ensure that the measurement reference surface is clean and free of debris, and maintain a constant measurement force on the probe.

Tool installation uses a thermal expansion tool holder to improve tool runout precision.

Operators perform tool alignment using a laser tool aligner to eliminate contact-based alignment errors.

Using a dial indicator, spindle end face alignment ensures that end face runout stays within the micrometer range.

Operators achieve tool wear compensation through online measurement to obtain real-time tool wear data.

Engineers establish pre-adjustment standards for different tool types.

For milling tools, radial runout is the primary measurement focus, while for drilling tools, length dimensions are prioritized.

Technicians control the pre-adjustment environmental temperature within a constant temperature range to minimize thermal deformation effects.

The system directly transmits measurement data to the CNC system via a network to avoid manual input errors.

Tool installation and removal processes use pneumatic wrenches to ensure stable installation torque.

Operators keep tool shank taper surfaces clean and regularly inspect taper accuracy.

Manufacturers use ceramic tool shanks for precision machining to reduce thermal expansion effects.

Engineers establish a tool life warning mechanism to remind users to replace tools based on processing hours.

Process Parameter Optimization Control Technology

Optimizing processing parameters is crucial for improving precision control effectiveness.

Engineers establish a cutting parameter library for different materials, creating a relationship model between feed rate, spindle speed, and cutting depth.

The cutting speed calculation formula in CNC machining is

v=πdn/1 000 (1)

where: v is the cutting speed,m · min-1; d is the workpiece diameter, mm;n is the spindle speed,r · min-1. The formula for calculating the cutting force generated during material cutting is:

F = Kc × ap × f (2)

where: F is the cutting force, N; Kc is the specific cutting force, N/mm²;ap is the cutting depth, mm; f is the feed rate per revolution, mm·r⁻¹ The cutting power formula is:

P = F × (v/60000) (3)Where: P is the cutting power, kW.

Operators control cutting parameters to prevent heat buildup in high-speed machining zones.

Operators adopt a layered cutting strategy in the low-speed finishing stage to ensure uniform machining allowance.

Select appropriate cutting speeds based on tool material properties;

carbide tools are suitable for high-speed cutting, while ceramic tools require impact control.

Technicians use micro-lubrication as cutting fluid to improve cooling and lubrication effects.

Monitor spindle load during the machining process and adjust parameters promptly upon detecting abnormalities.

Use large feed rates in the rough machining stage to improve efficiency, and reduce feed rates in the finishing stage to ensure surface quality.

Engineers determine optimal cutting parameter combinations through trial cuts and establish a process database.

Operators employ adaptive feed control during machining to adjust feed rates in real time.

Manufacturers use variable-speed cutting technology for complex curved surface machining to ensure stable cutting forces.

Engineers establish a cutting parameter optimization model to achieve a balance between machining efficiency and precision.

Technicians use specialized process parameters for machining special materials to ensure compliance with quality standards.

Implementation and Assurance of Precision Control Systems for Machinist Operations

System Integration for Precision Control of Machinist Operations

CNC precision control requires integrating process management, quality monitoring, and technical support.

Process management forms the foundation by establishing standards and procedures for precision control.

A process parameter database collects data by processing type to support optimization.

A library of process solutions summarizes successes for reference in similar workpieces.

The quality monitoring system uses real-time detection and early warnings at key points to quickly identify and fix issues.

Additionally, introduce intelligent analysis methods to deeply analyze collected data and identify key factors affecting precision.

Technical support ensures fixtures, gauges, and tools are well-managed and kept in optimal condition.

These three systems work together to form a closed-loop precision control system, ensuring improved processing quality.

Information sharing mechanisms should be established between systems to achieve data interoperability and improve overall operational efficiency.

Standardized Implementation of Precision Control

Standardization is a key means of achieving precision control.

Detailed work instructions define requirements and quality standards for key processes like clamping, tool alignment, and parameter settings.

Standard procedures must consider part characteristics and design specific, practical workflows.

Standardize operations to minimize human error, focusing on key control and quality monitoring points.

Establish evaluation and inspection systems with incentives to ensure strict standard adherence.

At the management level, standardize process document management, establish comprehensive quality inspection standards, formulate equipment maintenance and repair systems, and form a systematic management standard system.

Utilize information technology to achieve electronic management of process documents, enhancing traceability and operational efficiency.

At the training level, establish a position-specific skill training system and conduct regular operational skill training to enhance the skill levels of operators.

Training content should cover both theoretical knowledge and practical operations, employing diverse methods such as case-based teaching and on-site demonstrations to ensure training effectiveness.

Develop skill assessment standards and conduct theoretical and practical assessments to ensure that operators possess the necessary skills.

Establish a continuous improvement mechanism to promptly summarize lessons learned and continuously optimize and refine standard content.

Through standardization initiatives, precision control efforts are conducted in accordance with established procedures and guidelines.

Additionally, emphasize the dynamic optimization of standards, revising and improving them based on issues identified in production practice to ensure they remain advanced and practical.

Long-term mechanisms for precision assurance

Establishing long-term mechanisms is key to achieving continuous improvement in precision control.

In terms of technological innovation, establish a process technology innovation platform and organize technical research projects to address technical challenges encountered in production.

The innovation platform should integrate internal and external technical resources and establish a research-industry collaboration mechanism to provide a favorable environment for technological innovation.

Establish a mechanism for the conversion of innovation outcomes to promote the application of new technologies and methods in production.

In terms of quality improvement, formulate a quality continuous improvement plan, conduct regular process optimization reviews, and promptly identify and resolve quality issues.

Establish a rapid response mechanism for quality issues and form a professional technical team to tackle complex problems.

Systematically summarize precision control experiences, build technical expertise, and continuously enhance processing precision levels.

In terms of talent development, establish a skilled talent pipeline to cultivate and reserve professional technical personnel for the company.

Develop tiered talent development plans and adopt “mentor-apprentice” approaches to accelerate talent growth.

Create a technical exchange platform to facilitate experience sharing and technical collaboration among technical personnel.

Regularly organize technical seminars and experience-sharing sessions to foster a positive learning environment.

Establish a reasonable incentive and evaluation system to motivate technical personnel and stimulate their creativity.

Set up technical innovation awards and link innovation achievements to performance evaluations.

Through the establishment of long-term mechanisms, ensure that precision control work is continuously improved and enhanced.

Emphasize the implementation and supervision of mechanisms, regularly assess their operational effectiveness, and promptly optimize and improve them to ensure they consistently fulfill their intended functions.

Conclusion

Through a systematic analysis of the mechanisms by which machinist operations affect CNC machining accuracy, control technologies were proposed for critical processes such as clamping and positioning, tool alignment, and process parameter settings.

Based on this, an integrated system solution was developed that encompasses process management, quality monitoring, and technical support, establishing a standardized implementation framework and a sustainable assurance mechanism.

Through the establishment of operational standards, enhancement of personnel capabilities, and optimization of equipment management, a comprehensive precision control technology system has been formed.

The research findings emphasize the integration of theory and practice, addressing technical challenges while providing management solutions, thereby offering new technical approaches and management strategies to enhance the precision level of CNC machining.