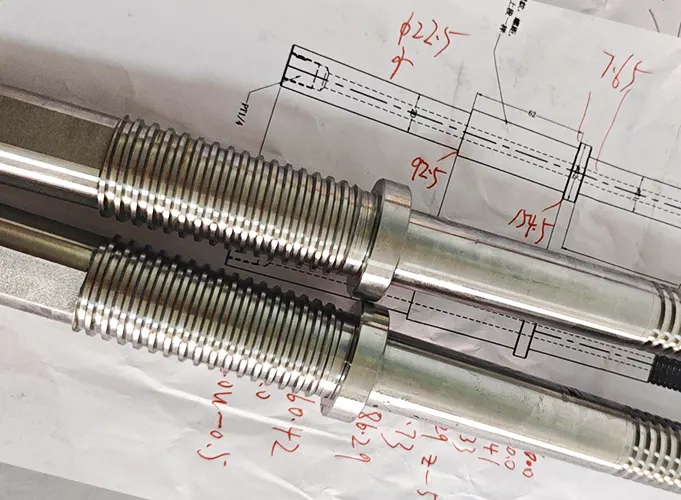

Threaded connection and screw drive in the engineering machinery is widely used, due to the different types of threads, the use of different occasions, so the processing of threads is directly related to the use of good and bad results.

The correct selection of suitable threads and the processing of qualified threads provide a guarantee for the production and use.

Types of threads

A thread is a spiral linear rib made on a machine, also called a screw buckle. According to the shape of its parent body, threads are divided into cylindrical threads and conical threads.

Based on their location, they are classified as internal threads and external threads. According to the direction of the helix, threads are divided into left-handed threads and right-handed threads. Right-handed threads are usually used.

Generally, right-hand thread is often used; according to the number of helical threads, it is divided into single thread, double thread and multi-thread, but generally not more than 4 threads;

Generally, single thread is used for connection, and double thread or multi-thread is used for transmission;

Classification according to the cross-section shape of the thread

According to the shape of the cross-section, threads—or tooth types—are divided into triangular threads, rectangular threads, trapezoidal threads, serrated threads, and other specially shaped threads.

Among these, the triangular thread is mainly used for coupling.

Among them, triangular threads are mainly used for coupling, rectangular threads, trapezoidal threads, serrated threads are mainly used for transmission;

According to the size of the teeth are divided into coarse threads and fine threads;

According to the use of the occasion can be divided into fastening threads, pipe threads, transmission threads, special threads.

Imperial threads and metric threads

China’s threads are divided into imperial threads and metric threads.

In addition to pipe threads, which are imperial, the rest of the threads are metric. Metric threads are also known as metric system threads.

The biggest difference between metric threads and imperial threads is that the pitch is measured in millimeters.

Metric threads include common threads, trapezoidal threads, rectangular threads, serrated threads and square threads.

Common threads include common threads, tapered pipe threads, pipe threads, trapezoidal threads, rectangular threads, and serrated threads.

The first three are mainly used for threaded couplings and the last three are mainly used for screw drives.

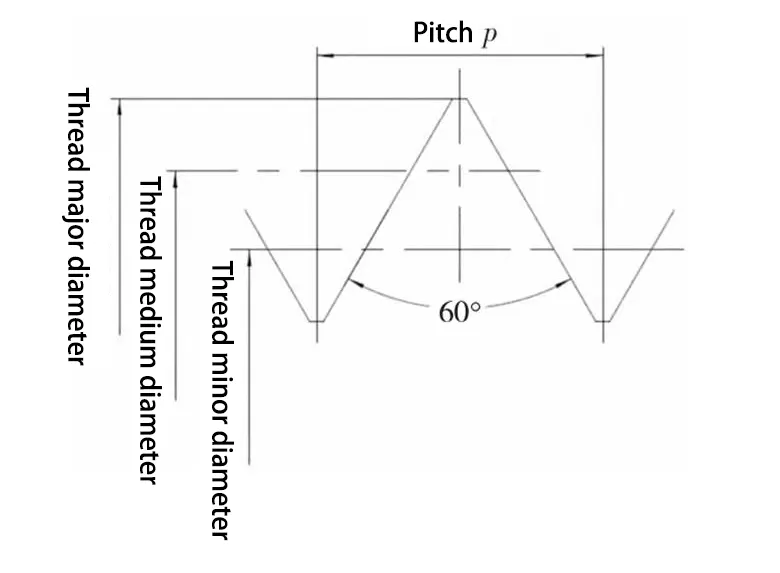

Ordinary thread

Ordinary thread refers to the tooth angle of 60 ° triangular thread, labeled with the letter M, is divided into coarse teeth and fine teeth of two kinds.

The diameter and pitch of coarse thread are moderate, good strength, and most widely used;

The fine thread has a large diameter and a small rise angle. As a result, it offers good self-locking performance and high strength. However, it is prone to slipping and is not wear-resistant.

Fine threads are suitable for thin-walled parts, dynamic load linkages, and fine-tuning mechanism adjustments. They are also used for connecting threads in hydraulic systems, but must be used with a sealing ring.

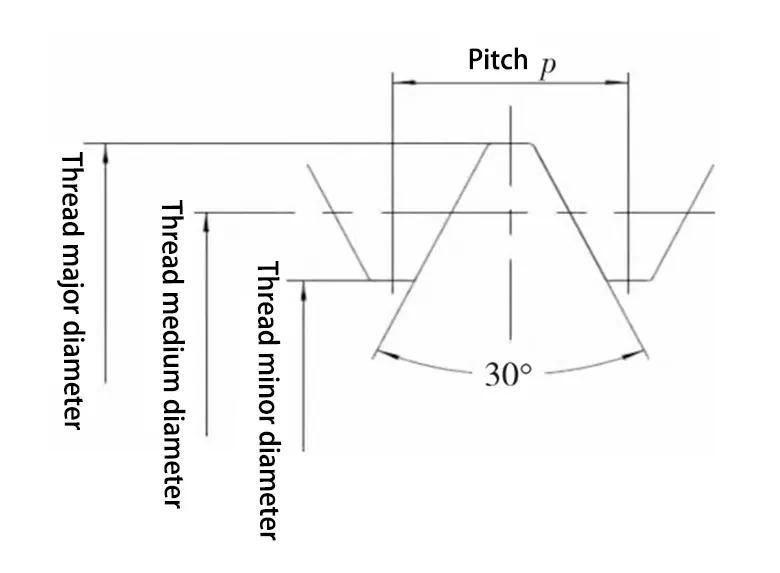

Ordinary threads are mainly used for fastening connections, and their thread profiles are shown in Figure 1.

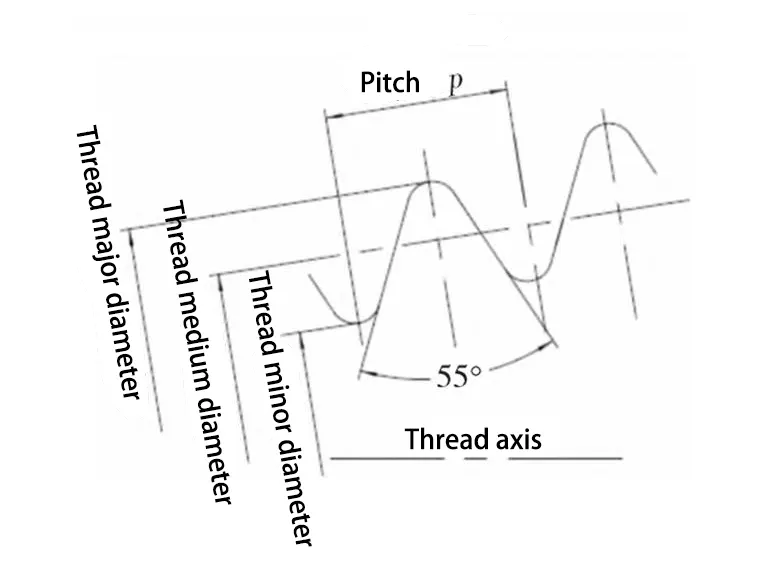

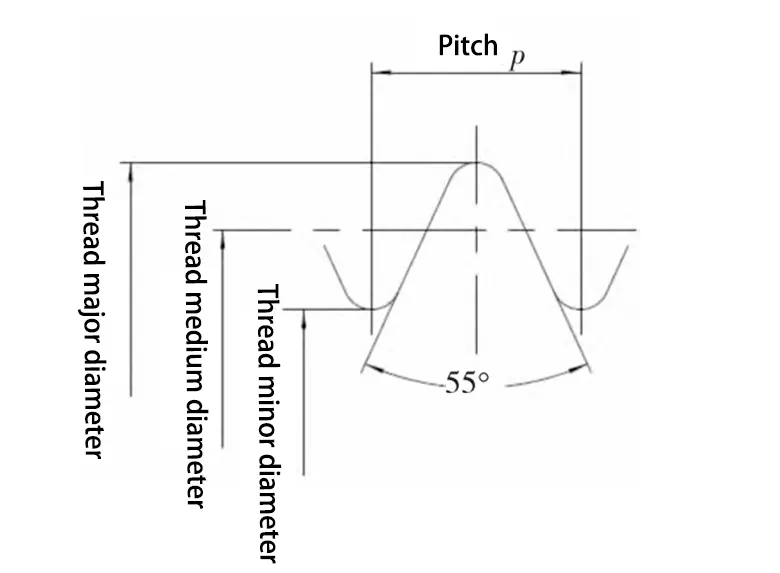

Pipe threads

Pipe threads are located on the pipe wall for coupling threads, mainly used for pipe coupling, so that the internal and external threads are closely matched, there are two kinds of straight and tapered pipe.

Metric pipe threads are generally divided into 55° sealed pipe threads and 55° non-sealed pipe threads.

(1) 55°sealed pipe thread.

It means that the angle of the thread is 55° and has a taper of 1:16.

Usually in the engineering drawings marked as R, Rc (R said with the cylindrical internal thread matching cone external thread; Rc: said cone internal thread) of the thread, as shown in Figure 2.

As the thread is screwed together, the deformation of its own thread can ensure the sealing of the thread.

Therefore, this kind of thread can be sealed, but the required pressure is not more than 16MPa. usually the conical male thread can be connected with the conical female thread and the cylindrical female thread.

2) 55° non-sealing pipe thread.

It is a thread usually labeled as G, as shown in Fig. 3. The thread itself does not have sealing, and must be fitted with a sealing washer when applied.

Usually used in hydraulic, lubrication system and other occasions of high pressure.

Tapered Pipe Threads

Tapered pipe threads, also known as NPT threads (National Pipe Thread), are a 60° tapered pipe thread derived from the American Standard.

The thread has a tooth angle of 60° and a taper of 1:16, and this thread has a certain degree of self-sealing. This thread is not commonly used domestically.

Trapezoidal thread

The trapezoidal thread has an angle of 30°, and its tooth shape is an isosceles trapezoid. Because the internal and external threads fit on a tapered surface, the connection is not easy to loosen.

As a result, trapezoidal thread couplings are widely used in mechanical transmission and fastening applications, such as lathe screws and drive screws.

Trapezoidal threads have high strength and good alignment, and are the most commonly used transmission threads.

Labeling usually with the letter “Tr” and nominal diameter × lead (pitch), as shown in Figure 4.

Rectangular threads

Rectangular thread tooth type is square, thread thickness is half of the pitch.

The transmission efficiency is high, but the centering accuracy is low, and the root strength is weak.

Currently only used for transmission efficiency has high requirements of the transmission system.

Because of its thread precision manufacturing is more difficult, spiral vice wear is difficult to repair and compensation, the use has been replaced by trapezoidal thread.

Serrated thread

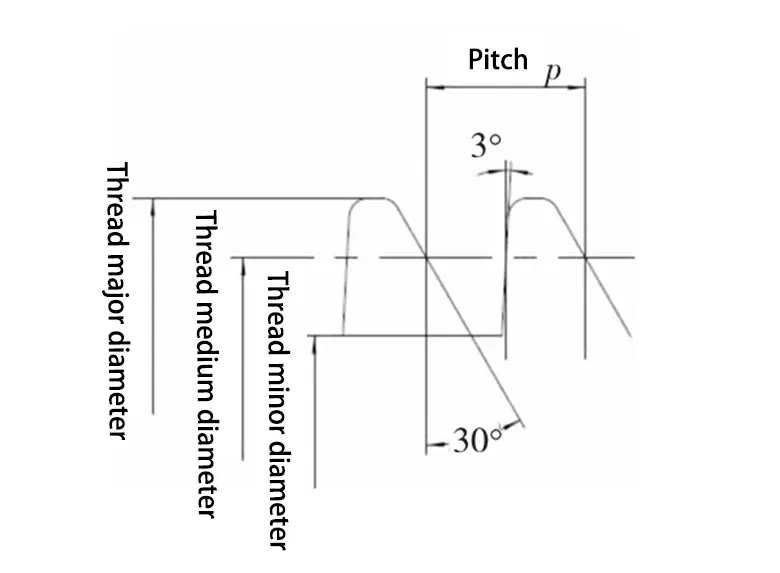

Serrated thread tooth type is not isosceles trapezoid, generally 33 ° and 45 ° serrated thread.

As shown in Fig. 5, 3° and 30° are in the plane through the thread axis and refer to the angle between the thread tooth side and the perpendicular to the thread axis.

A serrated thread with a 33° tooth angle has asymmetric teeth, 30° on one side and 3° on the other.

Its transmission efficiency is high, the root of the teeth is also strong, can withstand greater unidirectional pressure.

Mostly used in lifting machinery or pressure machinery, such as rolling equipment under the device. Labeling is usually indicated by the letter B.

Analysis of common defects in thread processing

In the daily actual production, often because of the thread processing defects and rework, rework, thus affecting the use of thread and production efficiency.

The common thread production methods are turning, rolling and grinding, and different processing defects are also different due to the choice of processing methods.

Turning thread

Turning threads, commonly referred to as picking threads, is usually performed on a lathe. During this process, the workpiece rotates one turn while the tool moves along the axis of the workpiece in a guided manner.

The movement of the tool’s blade creates a track that forms the thread surface on the workpiece.

Threads are formed by machine tool processing, and this form of processing is highly efficient and accurate.

Its common defects are as follows:

(1) The tooth parting line does not coincide with the axis.

The formation of this defect is generally caused by incorrect installation of the turning tool.

Often caused by carelessness or inexperience of the turner, as long as the position of the tool can be carefully calibrated to avoid.

(2) tooth angle is large or small.

This is generally caused by the knife blade grinding is not correct, the need for turners to check and regrind the knife edge.

3) Individual pitches are overshooting or have different pitch sizes.

This is due to the lathe screw and nut with a gap or screw runners or lathe claw jump caused by the need to check and adjust the screw vice, try to make the claw does not loosen can be.

(4) pitch cumulative error exceeded.

This is the lathe screw wear makes the transmission imprecision caused by the need to repair the screw, and then accurately calculate the transmission ratio, re-match the hanging wheel of the machine tool.

(5) Thread roughness is too poor or corrugated.

This is usually due to the lathe tool blade wear or blade with sticky chips caused by the need to sharpen the lathe tool or replace the lathe tool.

Rolling thread processing

Forming rolling molds are used to produce plastic deformation of the workpiece in order to obtain the thread.

This processing method is often referred to as thread rolling. It is generally carried out on a rolling machine or a thread rolling machine.

The product is better than turning precision, high production efficiency, suitable for mass production of standard fasteners and other threaded joints of the external thread.

Common thread defects are as follows:

(1) There are concave spots on the tooth side with poor roughness.

The reason may be that the workpiece material is not uniform, there are soft spots; the coolant is not clean with impurities; the roller tooth surface is not smooth due to.

It is necessary to check the material of the workpiece, replace or essence of the coolant or replace the roller according to the actual situation.

(2) Threaded tooth surface with heavy skin.

The reason may be the pallet or workpiece installation is not correct or not stable;

The shape of the workpiece is not good, there is a taper or ellipse; the roller has eccentricity or jumping, the two rollers overlap is not good.

This requires adjusting the pallet or pallet to make it mounted correctly. Or control the shape of the blank.

(3) The shape of the thread center diameter is not good.

This is due to improper installation of rollers or workpiece size is wrong or workpiece rigidity is poor.

Need to control the size of the workpiece, or adjust the roller rolling amount, rolling time, rolling speed.

(4) thread “messy buckle”.

The reason may be that the workpiece is not firmly installed, rolling in the tampering. Need to adjust the workpiece so that it is firmly installed.

(5) thread large and small diameter can not be qualified at the same time.

This is because the workpiece blank size is small. Need to strictly control the blank size.

Thread grinding

This is generally carried out on specialized thread grinding machines. Thread defects produced are as follows:

(1) The tooth side is not flat, shiny or straight.

This is usually due to the grinding wheel not grinding properly. There may be vibration in the grinding wheel, or the cutting dosage may be inappropriate.

It may also be caused by uneven movement of the diamond pen during wheel dressing, resulting in inconsistency.

Need to trim the grinding wheel, adjust the grinding head and clean the oil pool; ensure that the diamond pen and pen clip clearance is appropriate, screw fastening sufficient.

(2) The pitch is too poor.

Usually lies in the machine tool transmission system or screw wear; may also be the screw pitch and workpiece pitch ratio is not an integer multiple.

Need to repair the machine or replace the qualified screw;

Or the workpiece and the screw are rotating, lift the open and close the nut, wait for the screw to turn a revolution in the re-open and close the nut.

(3) tooth type is not correct, the bottom of the tooth radius is too large.

This is mainly because the grinding wheel dressing is not correct or grinding wheel hardness is not appropriate or grinding wheel wear.

Need to replace or adjust the grinding wheel.

Conclusion

Through the above introduction and analysis, recognize the commonly used thread type, according to the actual application of different needs to choose the thread that can meet.

At the same time, good products also need to ensure the manufacturing process.

Only to understand the causes of thread processing defects, in order to find and take timely measures to improve the actual production to improve.