Machining the input shaft in new energy gearboxes is difficult due to strict accuracy, tight tolerances, and a thin-walled structure.

Meanwhile, as the new energy passenger car market grows rapidly, competition in performance and price is intensifying.

We boost competitiveness in new energy shaft parts using advanced technology and double-head CNC turning, improving efficiency, quality, and cost.

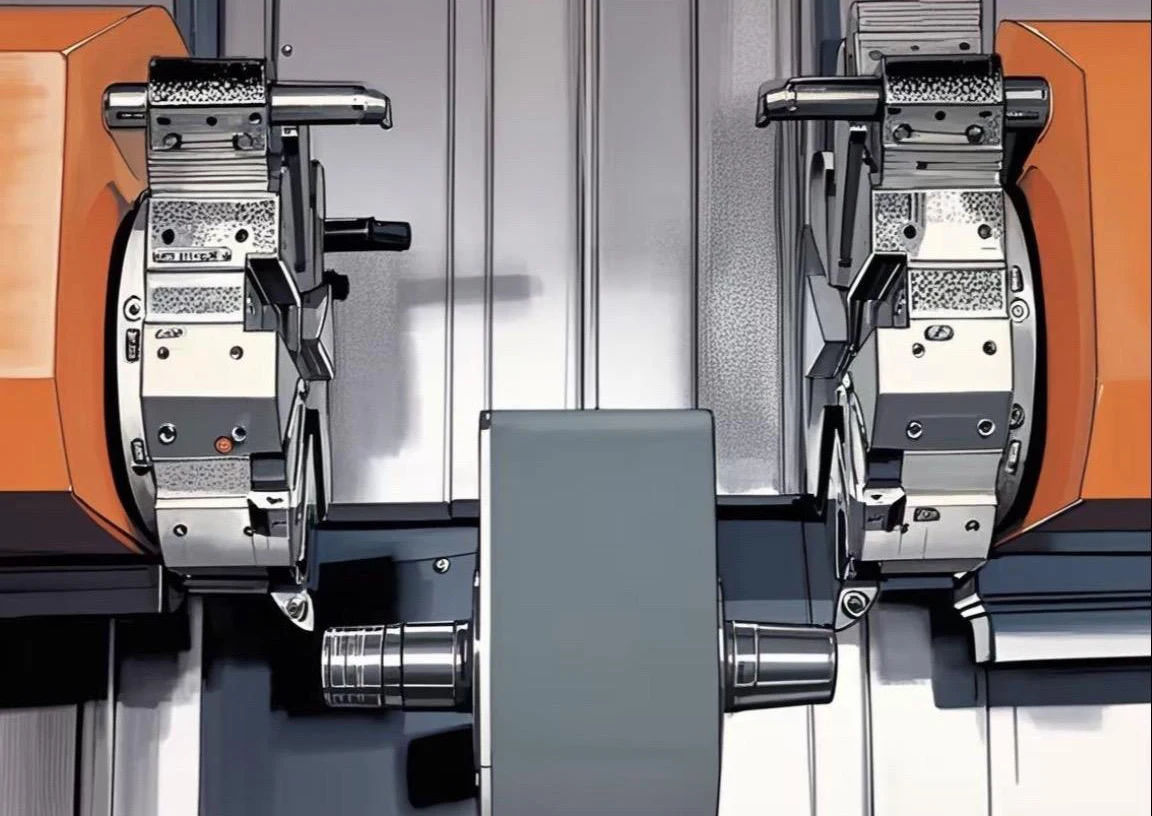

Double-head CNC lathe internal structure shown in Figure 1.

Double-head turning process program

After heat treatment, operators grind the teeth and machine the bearing ends and inner holes; the traditional process includes:

Grinding and turning the input shaft on five machines with multiple clamps risks accuracy, bumps, and rust.

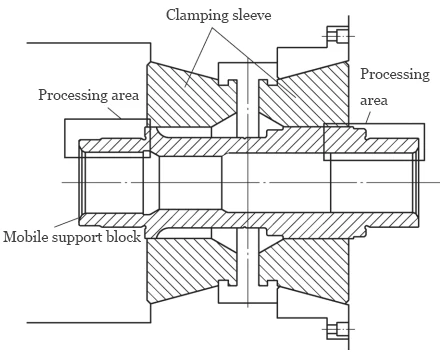

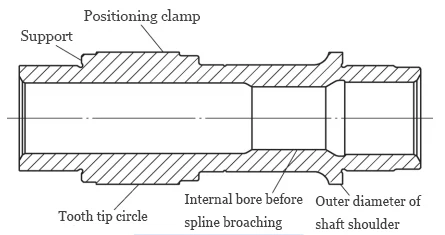

The double-head CNC lathe positions and clamps the shaft shoulder and tooth top using its support block and expansion sleeves.

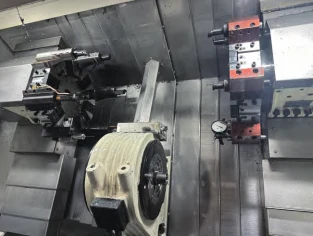

After clamping, the lathe’s dual turrets simultaneously machine the outer circle, end face, and bore (see Figure 2).

The double-head lathe’s multi-station turrets simultaneously machine the outer circle, end face, and inner hole at both ends.

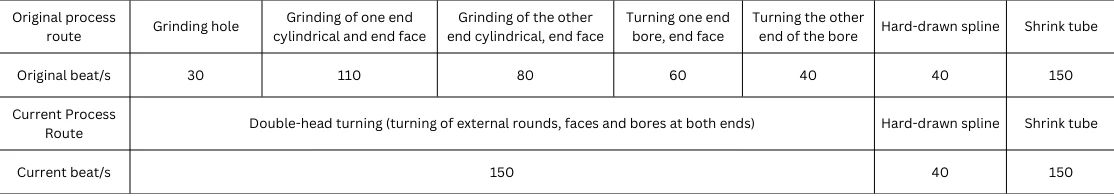

Comparison of machining efficiency

Table 1 shows the first five processes cut from 320s to 150s (+113%), and the whole process from 510s to 340s (+50%).

The double-head turning program improves efficiency, but engineers must verify its stability on the inner spline, outer circle, and bore runout.

Influence on positional tolerance

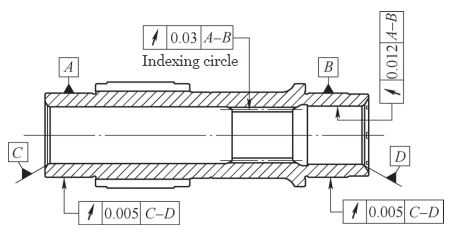

To ensure spline and tooth quality, engineers adopt the double-head turning program and strictly control outer circle runout.

The bearings’ outer circle runout affects tooth inclination, gear life, and NVH, so double-head turning must strictly control it.

Double-head turning process program geometric tolerance control requirements shown in Figure 3.

Influence on radial runout of internal spline

As a key input shaft feature, engineers must fully test the inner spline runout to ensure the machining process is 100% qualified.

In double-head turning, tooth top, shoulder, and bearing outer circles serve as references; poor coaxiality affects internal spline runout.

To ensure inner spline quality, double-head turning must control the blank, including minor diameter, tooth apex, and shoulder outer circle.

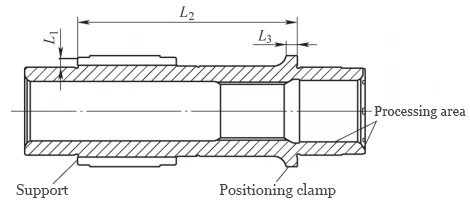

Before heat treatment, operators finish-turn one end and use the tooth end and top circle to support the other end.

Figure 4 shows the finishing turning program, where operators finish the shaft shoulder and spline bore with 10 μm coaxiality.

The spline bore takes the tooth top circle as the positioning reference, and its coaxiality with the tooth top circle is within 15μm.

For thin-walled input shafts, engineers optimize heat treatment to keep spline deformation within 10 μm.

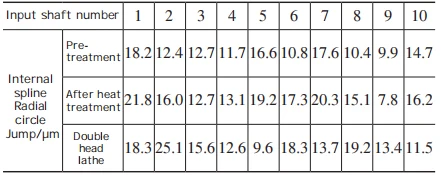

Engineers tracked the radial runout of 10 input shaft inner splines before and after heat treatment and double-head turning (Table 2).

Comparison shows that 8 internal splines have increased runout after heat treatment, with a maximum change of 10 μm.

Comparison shows that after double-head turning, 5 internal splines increased runout by up to 9.1 μm, and 5 decreased by up to 9.6 μm.

Max radial runout of 10 internal splines is 25.1 μm; the rest are within 20 μm, meeting process and product requirements.

Operators continuously processed over 500 pieces, keeping internal spline runout within 30 μm, with 100% pass rate and Cpk of 2.43.

Controlling blank quality and limiting deformation enables double-head turning to ensure stable internal spline quality.

Influence of circular runout on external circle and bore diameter

Operators reference the center hole in traditional heat treatment, keeping outer circle runout within 5 μm.

In CNC lathe (Figure 5), small clamps and long support often misalign the bore, failing runout requirements.

To ensure bore runout, operators must accurately position and grind the shaft shoulder and bearing outer circles together.

Inner hole and end face turning requires correcting all parts to keep bearing runout ≤8 μm and inner hole runout ≤12 μm.

This program adds post-heat-treatment grinding and turning, with repeated clamping and bore runout of 6–13 μm failing process requirements.

Double-head turning machines both ends in one clamping, keeping radial runout within 5 μm and solving original efficiency and runout issues.

Conclusion

Double-head turning machines both ends and holes in one clamping, reducing errors and improving accuracy and efficiency.

- Double-head turning after heat treatment replaces five traditional processes, enabling stable batch processing.

- Before heat treatment, the inner spline uses the tooth top for positioning (coaxiality ≤15 μm, runout ≤10 μm);

After heat treatment, double-head turning processes both bearing ends with the same reference.

After verifying 500 pieces, inner spline radial runout was 100% qualified and stably controlled within 30 μm.

- Double-head turning machines all holes in one clamping, keeping runouts and tooth dispersion within 5 μm.

FAQ:

Machining input shafts is challenging due to strict accuracy requirements, tight tolerances, thin-walled structures, and spline precision. Traditional processes require multiple machines and clamping, which increases the risk of deformation, runout, rust, and accuracy loss.

As the new energy passenger car market grows rapidly, manufacturers face higher demands for performance and lower costs. Improving machining efficiency, accuracy, and stability directly impacts competitiveness in the industry.

A double-head CNC lathe is an advanced machine with dual turrets that can simultaneously machine the outer circle, bore, and end face at both shaft ends. It reduces clamping steps, improves efficiency, and ensures geometric accuracy compared to traditional multi-machine setups.

According to process comparisons, the first five operations are reduced from 320s to 150s (+113%), and the entire process is shortened from 510s to 340s (+50%), significantly boosting production efficiency.

The method strictly controls outer circle runout, which affects tooth inclination, NVH performance, and bearing life. Using shoulder and tooth-top positioning, the lathe ensures coaxiality, runout, and dimensional stability during batch production.

Radial runout of the inner spline is critical for input shaft performance. Poor coaxiality of reference surfaces can increase runout, but double-head turning keeps internal spline runout within 30 μm, ensuring 100% qualification rates and Cpk = 2.43 in mass production.

Heat treatment may cause spline deformation up to 10 μm and runout variation. Engineers optimize pre-heat-treatment turning and adopt double-head clamping after heat treatment to minimize deformation and maintain accuracy.

Traditional processes using small clamps and long supports often lead to misalignment and bore runout failures (6–13 μm). Double-head turning, with single clamping of both ends, reduces radial runout to within 5 μm, meeting strict tolerance requirements.

Over 500 shafts were processed continuously, with inner spline runout controlled within 30 μm and 100% pass rate. This proves the process is stable and reliable for large-scale manufacturing.

Unlike traditional methods requiring five machines and multiple clamping operations, double-head CNC turning processes both ends and all holes in one clamping, minimizing errors, ensuring coaxiality ≤15 μm and runout ≤5–10 μm, while improving efficiency and cost-effectiveness.