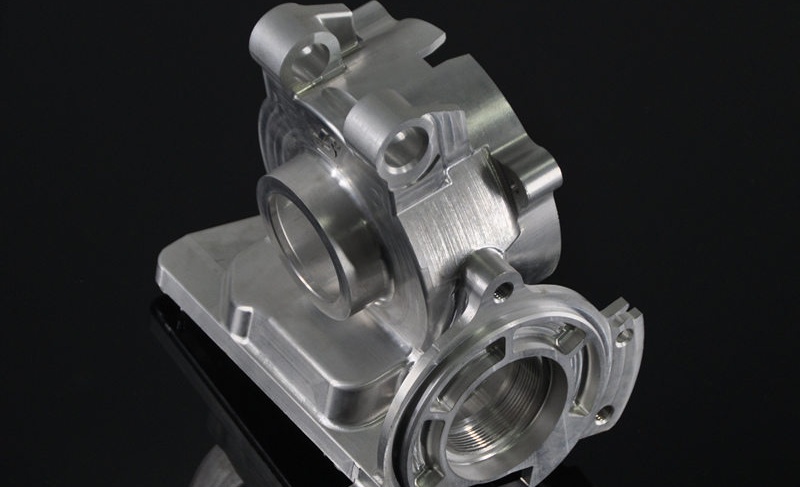

Aluminum Alloy Mold Manufacturing

Manufacturing aluminum alloy processing molds directly determines aluminum’s quality and service life. Aluminum extrusion tooling has specific characteristics, leading to high requirements for aluminum profile mold molding technology.

Challenges in Mold Materials

During extrusion, molds must endure high temperature, high pressure, and high friction. Manufacturers use high-strength heat-resistant alloy steel to meet these demands.

The processes of smelting, casting, forging, heat treatment, electrical machining, machining, and surface treatment for such steels are highly complex.

Advanced production equipment and skilled techniques are essential for mold manufacturers.

Precision and Surface Quality

To extend mold service life and ensure product surface quality, manufacturers maintain mold cavity roughness between 0.8-0.4 μm and mold plane roughness below 1.6 μm.

Special polishing processes and equipment are required to meet these standards.

High-precision extruded products, such as those with wall thicknesses around 0.5 mm and tolerances of ±0.05 mm, demand ultra-precise mold accuracy of 0.01 mm.

Manufacturers achieve this using CNC lathes, machining centers, and slow-wire processing machines.

Complex Cross-Sections

The cross-sections of aluminum profiles are often intricate.

Thin-wall hollow aluminum profiles and porous hollow-wall profiles require special extrusion mold structures.

A single mold may contain multiple shaped cavities with varying dimensions, complex features, and numerous arc corners.

This complexity necessitates the use of specialized structures and processing techniques.

Efficiency and Adaptability

Aluminum processing products often involve small batches, frequent mold changes, and diverse designs.

Manufacturers prioritize improving production efficiency and reducing the mold-making cycle.

They quickly modify processes to produce accurate molds based on drawings, minimizing the need for repairs.

Advanced Techniques and Equipment

Extrusion tools come in diverse types, have complex structures, and require strict assembly accuracy. To meet these challenges, manufacturers utilize specialized equipment, processing methods, tooling, and heat treatment techniques.

Additionally, advanced heat treatment and surface strengthening processes improve mold quality and service life.

These processes ensure optimal hardness and surface quality, especially for challenging extrusions and unique molds.

Conclusion

Aluminum extrusion die processing involves specialized, challenging technology.

Shenzhen Ruiyi Weiye Model Technology Co., Ltd. employs advanced equipment and high-grade materials to produce high-quality molds.

The company integrates cold working, electrical processing, heat treatment, and surface treatment techniques to achieve top-notch results.

FAQ:

The quality of the mold directly affects the surface finish, dimensional accuracy, and service life of aluminum alloy products.

Mold materials must withstand high temperatures, pressures, and friction. This requires using high-strength, heat-resistant alloy steel with complex processing and treatment.

Mold cavities must have a surface roughness between 0.8–0.4 μm, and mold planes must be below 1.6 μm to ensure high-quality surface finishes on products.

Products with wall thicknesses around 0.5 mm and tolerances of ±0.05 mm require mold accuracies as fine as 0.01 mm.

Manufacturers use CNC lathes, machining centers, and slow-wire EDM machines, along with specialized polishing equipment and techniques.

Many aluminum profiles have intricate, thin-walled, or hollow cross-sections. These require molds with multiple shaped cavities, arc corners, and specialized structural designs.

They enhance adaptability and efficiency by quickly modifying mold processes, shortening mold-making cycles, and reducing the need for repairs.

Advanced heat treatment and surface strengthening techniques improve the mold’s hardness, wear resistance, and service life—especially for complex and high-pressure applications.

Manufacturing demands specialized machinery, including precision CNC tools, heat treatment systems, polishing units, and accurate assembly tools.

Shenzhen Ruiyi Weiye Model Technology Co., Ltd. integrates cold working, electrical machining, heat treatment, and surface finishing processes with advanced equipment and skilled teams to produce top-quality molds.