Traditional machinery manufacturing relies on manual expertise and fixed processes, which hinder its ability to adapt to dynamic markets and complex environments.

However, with the introduction of artificial intelligence technology, this situation is undergoing a fundamental transformation.

AI enables prediction, decision optimization, and self-learning, revitalizing industrial machinery manufacturing.

Overview of Artificial Intelligence Technology

AI empowers machines to perceive, learn, reason, and decide, enabling task automation and supporting efficient human decisions.

Rapid advancements in big data, cloud computing, the Internet of Things, and other technologies have propelled AI toward leapfrog progress.

Advances in AI technologies drive applications from recognition and analysis to autonomous driving, healthcare, and finance.

For instance, in healthcare, AI assists physicians in analyzing vast medical imaging data, enhancing diagnostic accuracy and efficiency.

In the financial industry, AI-driven risk assessment and fraud detection significantly enhance the security and stability of financial systems.

Moreover, artificial intelligence plays a pivotal role in driving industrial upgrading and transformation.

It transforms manufacturing by enhancing efficiency and quality through predictive maintenance and intelligent scheduling.

In services, AI customer support and recommendation systems enhance user experience and efficiency.

Advantages

In today’s fiercely competitive manufacturing landscape, artificial intelligence technology is increasingly becoming a key driver of industry advancement.

For industrial machinery manufacturing, AI serves not merely as an emerging tool but as a critical enabler for optimizing production processes, enhancing quality, and reducing costs.

The following sections explore the advantages of AI in industrial machinery manufacturing from multiple perspectives.

Enhancing Production Efficiency

Traditional machinery manufacturing relies heavily on manual operations, which are slow, labor-intensive, and prone to errors.

AI technologies, like machine learning, enable intelligent scheduling and real-time production monitoring.

Systems can automatically analyze production data, predict equipment failures, and perform proactive maintenance, thereby minimizing downtime.

AI aids workers in precision tasks; for example, visual recognition guides robots to align components, improving speed and accuracy.

Furthermore, artificial intelligence plays a crucial role in production planning. AI analyzes production data, demand, and supply chains to create optimized plans, maximizing efficiency and capacity.

Intelligent production planning prevents overproduction, enables quick market responses, and boosts competitiveness.

Enhancing Product Quality

AI utilizes deep learning to analyze production data in real-time, detecting quality issues and defect patterns.

For instance, during machining processes, AI monitors critical parameters such as tool wear, workpiece dimensional changes, and surface roughness.

Upon detecting anomalies, it immediately issues alerts and adjusts production parameters to effectively prevent defective products.

Simultaneously, leveraging AI image recognition and machine vision technologies, AI systems enable comprehensive and efficient product inspection.

AI rapidly and precisely detects defects, ensuring all products meet quality standards.

Intelligent inspection improves efficiency and reduces human error and missed defects. Artificial intelligence also assists enterprises in establishing quality traceability systems.

AI tracks production data, material origins, and inspections, enabling fast, accurate analysis of quality issues.

Such traceability not only strengthens enterprises’ control over product quality but also enhances consumer trust and satisfaction.

Reducing Operational Costs

AI forecasts material demand and procurement, preventing overstocking, shortages, and wasted costs.

By optimizing inventory management, enterprises reduce capital tied up in stock and improve capital turnover rates.

AI monitors equipment energy use, identifies inefficiencies, and recommends optimizations to reduce consumption.

For instance, AI can intelligently adjust equipment operating parameters to maintain high production efficiency while lowering energy consumption.

AI forecasts energy prices and guides procurement strategies, reducing costs.

Furthermore, artificial intelligence technology helps lower enterprise maintenance costs. AI predicts and addresses equipment issues to prevent downtime and repair costs.

Applications

Artificial intelligence is reshaping the landscape of industrial machinery manufacturing by enabling smarter, data-driven, and automated processes.

Unlike traditional approaches that often rely on manual labor and fixed routines, AI introduces flexibility, adaptability, and predictive capabilities.

These advantages extend across the entire value chain, from design and production to maintenance and supply chain management.

The following sections will discuss the main benefits of AI, beginning with its role in enhancing production efficiency.

Mechanical Structure Design

In the field of mechanical structure design, the integration of artificial intelligence technology has revolutionized traditional design methods.

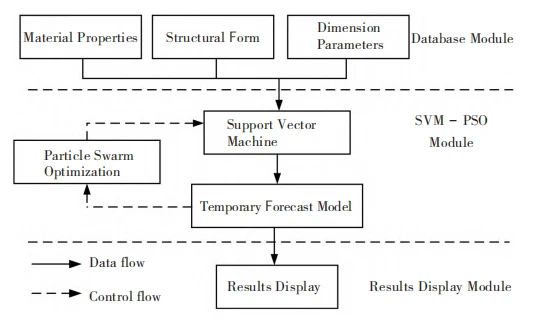

Researchers build a predictive model for mechanical design using PSO and SVM, comprising a database, an SVM-PSO module, and a results display (Figure 1).

The database module stores mechanical design data, including material properties, structures, dimensions, and stress and life predictions.

The data comes from historical records, research, and simulations, providing rich training and validation samples.

The SVM-PSO module constitutes the model’s core, integrating the strengths of Support Vector Machines (SVM) and Particle Swarm Optimization (PSO).

Support Vector Machines classify and predict mechanical structure design proposals, enabling rapid and accurate evaluation of design alternatives.

The PSO algorithm iteratively optimizes designs by mimicking the foraging behavior of birds or fish to find better solutions.

This integration endows the mechanical structure design prediction model with both robust classification capabilities and efficient optimization capabilities.

The results presentation module displays prediction and optimization outcomes to users in an intuitive and easily understandable manner.

3D modeling lets users visualize structure, stress, and lifespan under different designs, supporting decision-making.

Manufacturing Process Optimization

Deep learning, neural networks, and big data enable intelligent process upgrades, improving efficiency, quality, and cost control.

A deep learning scheduling model predicts equipment, labor, and material variables to enable precise production planning.

This model automatically adjusts production plans to ensure seamless coordination across all production stages, minimizing downtime and resource wastage.

It learns from historical data to identify bottlenecks and suggest optimizations, improving efficiency.

CNN-based image recognition monitors products in real-time, detecting surface defects and enhancing inspection accuracy.

Quality prediction models analyze historical data to forecast risks, enabling the implementation of preventive measures and enhancing product quality.

During the intelligent upgrade of manufacturing processes, AI technology also enhances production flexibility and customization.

A knowledge graph integrates and stores production knowledge, including equipment specs, process flows, and troubleshooting experience.

The system uses production knowledge to support adjustments, reducing changeover time and improving flexibility.

Intelligent Maintenance and Fault Prediction

In operation and maintenance, AI enables intelligent maintenance and fault prediction, supporting stable equipment operation.

Engineers can establish an intelligent monitoring system by integrating IoT technology with machine learning algorithms.

The system collects real-time parameters, such as vibration, temperature, and pressure, for cloud or edge analysis.

LSTM models analyze equipment patterns to predict failures, providing early warnings and minimizing downtime.

Furthermore, artificial intelligence demonstrates significant potential in fault diagnosis.

DNN and CNN fault diagnosis models extract features from large datasets to identify fault types, causes, and sometimes precise locations.

This improves fault diagnosis accuracy and efficiency while reducing reliance on manual expertise.

The formulation of intelligent maintenance strategies also benefits from AI technology.

Predictive maintenance analyzes equipment data to forecast the lifespan of components and optimize schedules.

On-demand maintenance prevents waste, keeps equipment optimal, and extends its lifespan.

Conclusion

In summary, the application of artificial intelligence technology in industrial machinery manufacturing has demonstrated immense potential and value.

From enhancing production efficiency and improving product quality to reducing operational costs, AI technology plays an irreplaceable role.

AI in design, process optimization, and predictive maintenance transforms manufacturing and advances industrial machinery toward greater intelligence.

FAQ:

Artificial intelligence is revolutionizing machinery manufacturing by replacing rigid, manual-dependent processes with intelligent, data-driven automation. AI improves adaptability, enhances decision-making, and introduces predictive capabilities that make manufacturing more efficient, flexible, and competitive in dynamic markets.

The three key advantages include:

Enhancing production efficiency through intelligent scheduling and real-time monitoring.

Improving product quality with machine vision and defect detection.

Reducing operational costs by optimizing inventory, energy consumption, and maintenance schedules.

AI boosts efficiency by automating scheduling, predicting equipment failures, and performing proactive maintenance. Machine learning algorithms analyze production data, enabling factories to minimize downtime and optimize output while quickly adapting to changes in demand.

AI applies real-time monitoring and machine vision to detect defects with high precision. By analyzing parameters such as tool wear, surface roughness, and dimensional changes, AI ensures early detection of anomalies, reduces errors, and strengthens product quality traceability.

Yes. AI forecasts material demand, optimizes procurement, and streamlines inventory management. Additionally, it monitors energy usage, suggests cost-saving adjustments, and predicts maintenance needs, all of which reduce waste, prevent unplanned downtime, and lower repair expenses.

AI-powered models, such as SVM-PSO (Support Vector Machines with Particle Swarm Optimization), predict and optimize mechanical designs. These models classify design alternatives, optimize performance through iterative simulations, and provide 3D visualizations for better decision-making.

AI uses deep learning and big data to upgrade processes by predicting variables, preventing bottlenecks, and enabling real-time defect detection with computer vision. Knowledge graphs also help streamline adjustments, improving flexibility and customization in production.

By combining IoT sensors with machine learning, AI collects real-time equipment data (e.g., vibration, temperature, pressure) to predict potential failures. Models like LSTM, DNN, and CNN enable early fault detection, accurate diagnosis, and predictive maintenance scheduling to extend machine lifespan.

AI applications extend beyond manufacturing into sectors like healthcare (medical imaging and diagnostics), finance (fraud detection and risk assessment), and services (customer support and recommendation systems). These fields benefit from AI’s ability to process large datasets and optimize decisions.

The future points toward fully intelligent factories where AI handles design, production, quality control, and predictive maintenance. This evolution will drive industrial upgrades, enable highly flexible production, and ensure sustainable competitiveness in global markets.