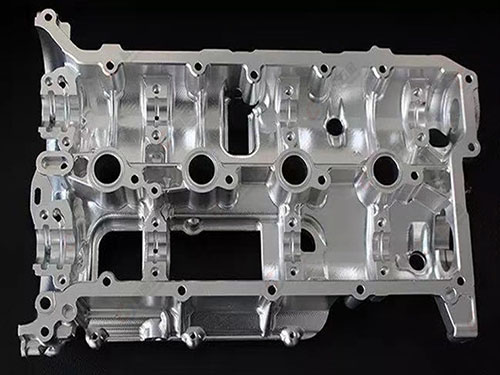

In recent years, the demand for China CNC precision hardware processing has expanded significantly across various industries. However, along with this growth, the requirements for part precision, quality, and efficiency have become increasingly stringent.

Particularly for aluminum alloy processing, manufacturers must rely on both advanced technology and deep industry experience. Below are four critical aspects that CNC precision hardware processing factories in China must pay special attention to.

1. Engineering Drawings: The Core of Precision Machining

Drawings Define Accuracy

In CNC precision machining, technical drawings play a central role. They not only communicate the geometric shape and dimensions of a part but also specify essential tolerances related to shape, position, and surface finish.

If these details are omitted or unclear, it may result in parts that do not meet the intended functional standards.

Guiding the Entire Workflow

A well-designed drawing guides every aspect of production:

Helps determine processing routes

Aids in selecting the right tools

Allows for scientific scheduling of production

Ultimately improves manufacturing efficiency and consistency

2. Raw Materials: The Foundation of Quality Parts

Importance of Material Selection

As the saying goes: “A clever woman can’t cook without rice.” The same principle applies in CNC precision machining—without high-quality raw materials, no amount of skill or equipment can produce superior products.

Industry Application Demands

Industries such as:

Automotive

Aerospace

Medical devices

All rely heavily on parts with high strength, aesthetic appeal, and material consistency. Therefore, using certified, high-performance alloys is essential for both functionality and durability.

3. Cost Control and Cycle Time Management

Rising Costs, Falling Prices

While market competition drives down product pricing, raw material and labor costs continue to rise. To maintain profitability, manufacturers must:

Analyze and control variable costs early

Implement lean production principles

Improve yield rates and minimize rework

Importance of Production Planning

Proper planning reduces the risk of delays, quality issues, and bottlenecks. This includes:

Scheduling orders realistically

Avoiding rushed deliveries

Monitoring lead times and resource utilization

4. Surface Treatment, Packaging, and Transportation

Surface Protection

After machining, parts—especially aluminum components—must undergo surface treatments such as:

Anodizing

Sandblasting

Anti-corrosion coatings

These processes enhance durability and aesthetic appeal while preventing oxidation or wear.

Safe Packaging and Delivery

To ensure parts arrive in perfect condition:

Use custom-fit foam or protective layers to prevent compression and deformation

Label packaging clearly to avoid mishandling during transportation

Consider climate control for sensitive components

Delivering products intact and within tolerance is a final but crucial part of maintaining quality.

Conclusion: Achieving Excellence in CNC Precision Manufacturing

To stay competitive in the precision machining industry, Chinese CNC factories must focus on:

Rigorous technical documentation

Quality material sourcing

Thoughtful cost control and planning

Comprehensive finishing and logistics

By addressing these critical factors, manufacturers can consistently produce high-quality, high-precision components that meet the demanding needs of modern industries.

Add Your Heading Text Here

Engineering drawings define part accuracy by specifying the geometric shape, dimensions, tolerances, and surface finish. Clear and accurate drawings ensure parts meet functional standards.

The quality of raw materials directly affects product performance, durability, and aesthetic appeal. High-performance alloys are essential for industries like automotive, aerospace, and medical devices.

Drawings determine processing routes, help select the right tools, and allow for scientific scheduling, improving production efficiency and consistency.

Rising raw material and labor costs increase pressure on manufacturers, requiring efficient cost control strategies like lean production and improved yield rates to maintain profitability.

Proper production planning reduces delays, quality issues, and bottlenecks. It includes realistic scheduling, avoiding rushed deliveries, and monitoring lead times and resource utilization.

Aluminum parts often require anodizing, sandblasting, and anti-corrosion coatings to enhance durability, aesthetic appeal, and prevent oxidation or wear.

Custom-fit foam or protective layers should be used to prevent damage during transport, while clear labeling and climate control for sensitive components can ensure products arrive in perfect condition.

Industries such as automotive, aerospace, and medical devices rely heavily on CNC machining to produce parts with high strength, precision, and material consistency.

High-quality raw materials, accurate engineering drawings, and advanced machining techniques ensure that CNC precision hardware meets stringent quality standards while maintaining high production efficiency.

Manufacturers must focus on rigorous technical documentation, quality material sourcing, cost control, production planning, and comprehensive finishing and logistics to consistently meet the demands of modern industries.