3D printing, or additive manufacturing, has become over the years a reliable manufacturing method and used in many sectors.

But do you really know what this technology is, how it works, and what its possible applications are?

What is 3D Printing?

This method is becoming more popular for creating proofs of concept, prototypes, and final products.

Companies are adopting this technology at different levels of their production, rethinking their business strategy with this competitive advantage.

Engineers, designers and hobbyists are developing innovative applications using this technology.

This method creates objects layer by layer based on a 3D digital model.

The process literally transforms the digital version of an object into a physical version.

How It Works?

There is no single method for additive manufacturing. Indeed, when considering this technology, many people still think of FDM printing.

But 3D printing is much more than that. There are currently several techniques for creating parts additively.

You will determine the choice of material and technology according to the nature of your project.

What properties do you need? What resistance? Here’s how the main printing technologies work.

3D Plastic Printing

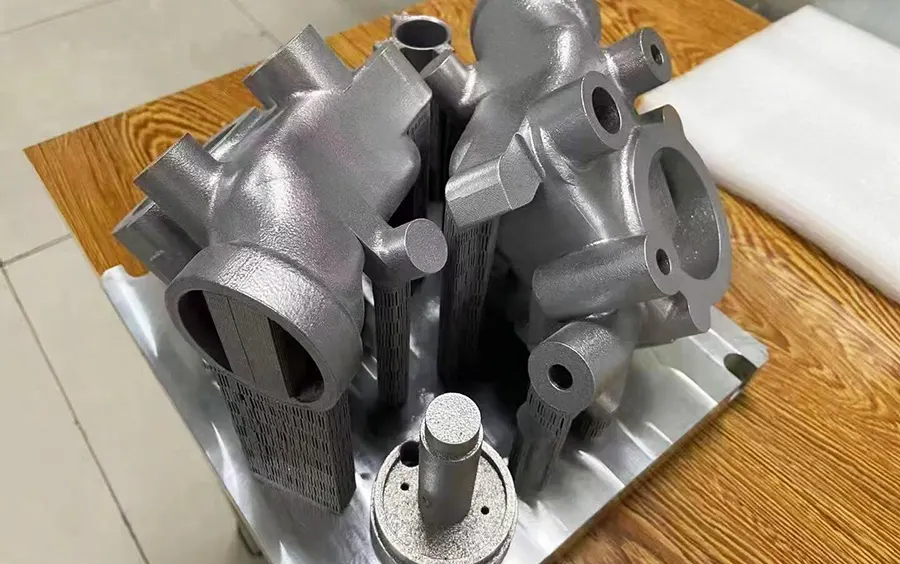

The Sintering Selective Laser, or SLS: This 3D printing technique created objects by sintering the powder inside the printer using a laser.

During a layer-by-layer process, the system preheats the powder bed, and a laser sinters the powder according to the 3D file to create a solid object.

Amateurs and the education community well know this 3D printing method, Filing or FDM.

FDM printers use one or two print heads to deposit molten material.

The printer melts and extrudes the material through the nozzle to create the desired object, layer by layer.

People mainly know FDM printing as a plastic printing technique, but now it is possible to use it to print metal.

3D Resin Printing

CLIP, or DLS: DLS technology is developed by Carbon and works by projecting a continuous sequence of UV images, generated by a digital light projector, through a UV-transparent glass behind a resin bath.

The dead zone above the glass creates and maintains a liquid interface behind the part.

A machine extracts the hardened part from the resin bath above the dead zone.

Polyjet: This resin 3D printing technology projects layers of curable photopolymer liquid onto a print bed. The software calculates the placement of the photopolymers and the support material during the pre-process step.

Then, during the resin 3D printer printing projects and processes with UV small drops of liquid photopolymer.

FAQ:

3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects layer by layer from a digital model. It transforms a virtual design into a physical object by successively adding material until the final shape is achieved.。

3D printing starts with a digital 3D model created using CAD software. The printer then builds the object layer by layer, following the digital design. Depending on the chosen technology, materials such as plastic, resin, or metal are melted, sintered, or cured to form solid structures.

There are several 3D printing technologies, including:

FDM (Fused Deposition Modeling) – melts and extrudes thermoplastic material.

SLS (Selective Laser Sintering) – uses a laser to fuse powdered material.

SLA/DLP/CLIP – cures liquid resin using UV light.

PolyJet – sprays layers of photopolymer and cures them with UV light.

Each technology is chosen based on the material type, precision, and application required.

3D printing supports a wide range of materials, including:

Plastics (PLA, ABS, Nylon)

Resins (standard, flexible, or high-strength)

Metals (stainless steel, titanium, aluminum)

Composites and other specialized materials depending on the printer type.

3D printing is used for:

Prototyping and product development

Tooling and custom fixtures

Medical and dental implants

Aerospace and automotive components

Consumer goods and design models

It is valuable for creating both proofs of concept and final production parts.

FDM (Fused Deposition Modeling): Uses melted plastic filament extruded through a nozzle; ideal for basic prototypes.

SLS (Selective Laser Sintering): Uses a laser to fuse powdered material; strong and durable results.

Resin Printing (SLA, DLP, CLIP, PolyJet): Uses UV light to cure liquid resin; provides smooth, high-resolution surfaces.

Fast prototyping and design flexibility

Reduced material waste

Lower tooling costs

Customization and small-batch production

Complex geometries that traditional machining cannot achieve

Yes. Many industries now integrate 3D printing into their production lines. It’s used for low-volume manufacturing, customized parts, and lightweight components, allowing businesses to reduce time-to-market and production costs.

The choice depends on:

Desired material (plastic, resin, or metal)

Strength and mechanical requirements

Surface finish and accuracy

Production volume and cost

Consulting with a professional 3D printing service provider helps ensure the best technology for your application.

3D printing allows companies to prototype faster, reduce design risks, and produce customized parts on demand. This flexibility enhances innovation, shortens production cycles, and significantly lowers manufacturing costs — giving businesses a strong competitive edge.