Precision measurement is a cornerstone of modern manufacturing and quality control, and instruments such as vernier calipers and micrometers play a vital role in ensuring dimensional accuracy.

This article provides a comprehensive overview of these two commonly used precision measuring tools, explaining their structure, working principles, reading methods, proper usage, and essential precautions.

By understanding how to correctly operate vernier calipers and micrometers, users can achieve reliable, repeatable measurements and avoid common sources of error in industrial and workshop environments.

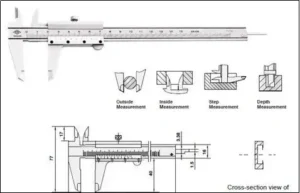

Vernier calipers are commonly used industrial instruments for measuring length.

They can be directly employed to measure workpieces with high precision, such as the length, inner diameter, outer diameter, and depth of components.

Overview of Vernier Calipers

As a widely used high-precision measuring tool, vernier calipers consist of two parts: the main scale and the vernier scale, which slides along the main scale.

Based on the vernier scale’s graduation value, vernier calipers are categorized into three types: 0.1 mm, 0.05 mm, and 0.02 mm.

Reading a Vernier Caliper

Using a precision vernier caliper with a scale value of 0.02mm as an example, the reading method can be divided into three steps:

1) Read the whole millimeter value from the nearest mark on the main scale to the left of the zero line on the vernier scale;

2) Read the decimal value by multiplying the number of lines aligned with the main scale to the right of the zero line by 0.02;

3) Add the whole number and decimal parts together to obtain the total dimension.

Reading Method for 0.02mm Vernier Calipers

As shown in the figure above, the 64mm mark on the main scale corresponds to the zero line of the vernier scale.

The ninth line after the zero line aligns with one of the main scale’s graduations.

The ninth line after the vernier zero line indicates: 0.02 × 9 = 0.18mm

Therefore, the measured dimension of the workpiece is: 64 + 0.18 = 64.18mm

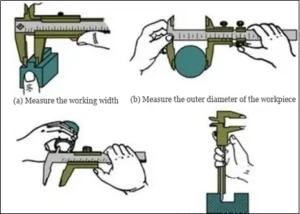

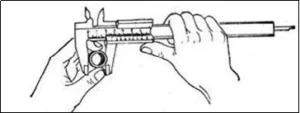

How to Use Vernier Calipers

Close the jaws and check whether the zero mark on the vernier scale aligns with the zero mark on the main scale. If aligned, proceed with measurement.

If not aligned, record the zero error: – If the zero mark on the vernier scale is to the right of the zero mark on the main scale, it is a positive zero error.

If the zero mark on the vernier scale is to the left of the zero mark on the main scale, it is a negative zero error.

(This convention aligns with the number line convention: values to the right of the origin are positive, and values to the left are negative.)

During measurement: Hold the main scale body with your right hand, moving the vernier with your thumb.

Hold the object with the outer diameter (or inner diameter) to be measured in your left hand, positioning it between the outer measuring jaws.

When the object is firmly pressed against the measuring jaws, take the reading as shown below:

Applications of Vernier Calipers

As a commonly used measuring tool, vernier calipers can be specifically applied in the following four areas:

1) Measuring workpiece width

2) Measuring workpiece outer diameter

3) Measuring workpiece inner diameter

4) Measuring workpiece depth

For specific measurement methods in these four areas, please refer to the diagram below:

Precautions for Use

Vernier calipers are precision measuring tools. Observe the following precautions during use:

1. Before use, wipe clean both measuring surfaces of the jaws.

Close the jaws and check whether the zero line of the vernier scale aligns with the zero line of the main scale.

If misaligned, correct the reading according to the initial error.

2. When measuring workpieces, the measuring surfaces of the jaws must be parallel or perpendicular to the workpiece surface without tilting.

Avoid excessive force to prevent jaw deformation or wear, which could compromise measurement accuracy.

3. When reading measurements, ensure your line of sight is perpendicular to the scale surface; otherwise, readings will be inaccurate.

4. When measuring internal diameters, gently rock the caliper to locate the maximum dimension.

5. After use, thoroughly clean the vernier caliper, apply protective oil, and store it flat in its case to prevent rusting or bending.

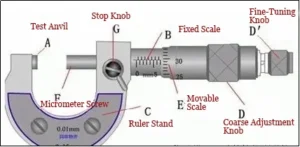

The micrometer, also known as a micrometer gauge, is a precision measuring tool. The following explains its principle, structure, and usage methods.

What is A Micrometer?

A micrometer, also known as a micrometer caliper or vernier micrometer, is a precision measuring tool for lengths that is more accurate than a vernier caliper.

It can measure lengths with an accuracy of 0.01mm and has a measurement range of several centimeters.

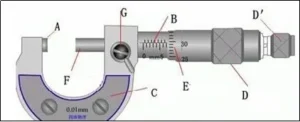

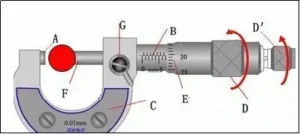

Structure of the Micrometer Screw Gauge

The following is a schematic diagram of the micrometer screw gauge structure:

Working Principle of the Micrometer Screw Gauge

The micrometer screw gauge operates on the principle of screw amplification.

This means that for every full revolution of the screw within the nut, the screw advances or retracts along its axis by one pitch.

Consequently, minute axial displacements can be represented by readings taken circumferentially around the screw.

The precision thread pitch of the micrometer is 0.5mm, with the movable scale divided into 50 equal graduations.

One full rotation of the movable scale advances or retracts the micrometer screw by 0.5mm.

Therefore, each small division corresponds to an advance or retraction of 0.5/50 = 0.01mm.

Thus, each minor division on the movable scale represents 0.01 mm, enabling the micrometer to achieve an accuracy of 0.01 mm.

Since an additional estimated reading can be made, allowing measurement to the thousandth of a millimeter, it is also known as a micrometer.

How to Use a Micrometer

When assisting customers in connecting our data acquisition instruments to micrometers for efficient measurements, we consistently advise them to follow these steps:

1.Check zero point before use: Slowly turn the fine adjustment knob D′ until the measuring rod (F) contacts the anvil (A), stopping when the ratchet clicks.

At this point, the zero mark on the movable scale (movable sleeve) must align with the reference line (long horizontal line) on the fixed sleeve. Failure to align will result in zero error.

2.Hold the caliper frame (C) with your left hand. Use your right hand to turn the coarse adjustment knob D until the distance between the measuring rod F and the anvil A is slightly greater than the object being measured. Place the object into position.

Turn the protective knob D′ to clamp the object until the ratchet clicks. Engage the locking knob G to secure the measuring rod, then take the reading.

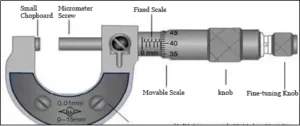

Reading Method for Micrometers

1. First read the fixed scale.

2. Next read the half-scale: if the half-scale line is exposed, record as 0.5mm; if not exposed, record as 0.0mm.

3. Then read the movable scale (note estimated reading), recorded as n × 0.01mm.

4. The final reading is the sum of the fixed scale + half-division + movable scale.

Since micrometers provide readings accurate to thousandths of a millimeter, they are also called micrometers.

Precautions for Using a Micrometer

1. When measuring, stop using the main knob as the micrometer screw approaches the object being measured.

Switch to the fine adjustment knob instead to avoid excessive pressure. This ensures accurate results and protects the micrometer.

2. When reading the measurement, check whether the half-millimeter mark on the fixed scale is fully exposed.

3. The thousandths digit is an estimated reading and must not be discarded arbitrarily.

Even if the zero point of the fixed scale aligns perfectly with a mark on the movable scale, the thousandths digit should still be read as “0”.

4. When the anvil and micrometer screw are fully closed, the zero point of the movable scale may not align with the fixed scale’s zero point, resulting in a zero error.

This must be corrected by subtracting the zero error value from the final measured length reading.

Proper Use and Maintenance of Micrometers

1. Verify the accuracy of the zero line;

2. Clean the workpiece surface to be measured before taking readings;

3. Place larger workpieces on a V-block or flat plate for measurement;

4. Clean the measuring rod and anvil before measurement;

5. Use the ratchet mechanism when turning the movable sleeve;

6. Do not loosen the rear cover to prevent zero line displacement;

7. Do not apply ordinary machine oil between the fixed and movable sleeves;

8. After use, wipe clean, apply oil, store in the dedicated case, and keep in a dry place.

Conclusion

Vernier calipers and micrometers are indispensable tools for accurate length measurement, each offering distinct advantages in terms of range and precision.

Mastery of their reading techniques, correct handling procedures, and maintenance practices is essential for obtaining trustworthy measurement results.

By carefully checking zero errors, applying appropriate measuring force, and following proper storage and care guidelines, users can maximize instrument accuracy and service life.

Proper use of these precision instruments ultimately enhances measurement reliability, supports quality assurance, and contributes to higher standards in manufacturing and inspection processes.

FAQ

What is the difference between a vernier caliper and a micrometer?

A vernier caliper is a versatile measuring instrument used for external, internal, depth, and step measurements, typically offering accuracy up to 0.02 mm. A micrometer, on the other hand, provides higher precision—up to 0.01 mm or better—and is mainly used for highly accurate external dimension measurements. Micrometers are preferred when tighter tolerances are required.

How do you correctly read a 0.02 mm vernier caliper?

To read a 0.02 mm vernier caliper, first record the whole millimeter value from the main scale to the left of the vernier zero line. Then identify the vernier scale line that aligns with a main scale mark and multiply its number by 0.02 mm. Adding these two values gives the final measurement, ensuring accurate dimensional readings.

Why is zero error important when using precision measuring tools?

Zero error occurs when the measuring jaws or anvils are fully closed but the scale zeros do not align. If uncorrected, zero error leads to systematic measurement inaccuracies. Identifying and compensating for positive or negative zero error ensures reliable, repeatable measurements and is essential in precision inspection.

What types of measurements can be performed with vernier calipers?

Vernier calipers can measure workpiece width, outer diameter, inner diameter, and depth. Their multi-functional jaws and depth rod make them ideal for general-purpose dimensional inspection in machining, manufacturing, and maintenance applications.

How does a micrometer achieve higher accuracy than a vernier caliper?

A micrometer operates on the screw amplification principle, using a precision-threaded screw with a known pitch. Each rotation advances the measuring spindle by a fixed distance, allowing extremely small dimensional changes—typically 0.01 mm per division—to be measured accurately, making micrometers ideal for high-precision applications.

What are the best practices for maintaining vernier calipers and micrometers?

Proper maintenance includes cleaning measuring surfaces before and after use, applying correct measuring force, checking zero alignment, and storing instruments in a dry protective case. Avoid excessive pressure, use ratchet mechanisms on micrometers, and apply light protective oil to prevent wear and corrosion, ensuring long-term measurement accuracy.