Programming technology for CNC mill-turn machine tools is currently the main bottleneck affecting their application. Although many CAM software are available, most do not offer solutions for mill-turn compound machining, making programming difficult.

Mill-turn programming typically involves classifying and sequencing processes, then using CAM software to plan and integrate milling and turning. However, the rapid development of mill-turn technology has raised higher programming demands, becoming a bottleneck in production.

Mill-turn technology is new, so many times programs are generated with general CAM software and then manually integrated by craftsmen. This method not only requires the high skills of craftsmen but also the programming process is cumbersome. Therefore, it is particularly important to study the manual programming of mill-turn machining centers, especially the C-axis programming method.

Characteristics of CNC turning and milling compound machine tool

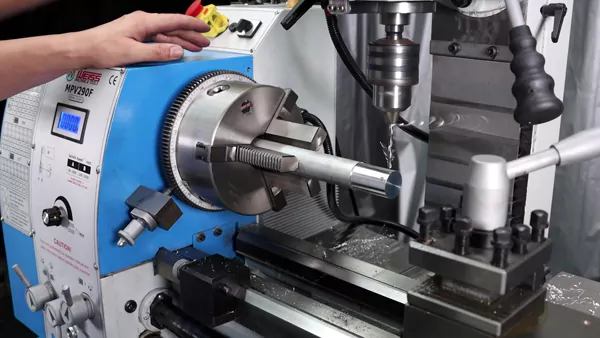

CNC mill-turn compound machine tool is a high-performance machine tool that integrates the functions of a lathe and milling machine. It achieves multi-process machining by installing lathe tool holders and milling spindles on the same table, offering high integration, efficiency, and suitability for precision and mass production. The following are the main features of CNC mill-turn machine tools:

1. Highly integrated

The CNC milling machine tool will be integrated with the lathe tool holder and milling spindle, enabling various machining operations on a single worktable. This design boosts efficiency, reduces workpiece handling and clamping, and enhances accuracy and productivity. Due to its precision machining capability, CNC mill-turn machine tools have significant advantages in the processing of high-precision requirements.

2. High efficiency

CNC mill-turn machines use multi-axis parallel control for efficient multi-face and multi-angle machining, allowing simultaneous turning and milling on the same workpiece, reducing machining time. They also support automated programming, saving manual labor and costs.

3. Widely used

CNC turning and milling machine tool has a wide range of applications in the field of machining. CNC mill-turn machine tools are key equipment in industries like aviation, aerospace, automotive, mold, machinery, and nuclear energy, meeting high precision and efficiency demands in areas such as axle machining, propeller machining, and large-scale vertical machining.

The basic principle of CNC machine tool programming technology

CNC programming controls machine tool motion to achieve precise workpiece machining. The basic principle of CNC machine tool programming technology involves three aspects: mathematical model, language specification, and program generation.

1. Mathematical model

CNC machine tool programming is based on a mathematical model that describes the geometry and spatial location of the workpiece, including coordinate systems, points, lines, surfaces, and other elements. This ensures accurate movement control while meeting the machining requirements for precision and efficiency. Through precise mathematical modeling, it can ensure the accuracy and stability of CNC machine tools in the machining process.

2. Language specification

The language specification in CNC programming ensures the program follows rules and format for correctness and readability. Currently, the programming of CNC machine tools mainly uses G code and M code two languages. G code controls the machine’s cutting actions and trajectory, while M code manages auxiliary functions like coolant, alarms, and spindle control l. The standardization and unity of programming is ensured by the standardized programming language.

3. Program Generation

Program generation is the core of CNC programming, creating machining programs by combining the object’s mathematical model with the programming language specification. The program describes in detail the workpiece machining process, machining sequence, cutting parameters, and so on. Program generation can be done manually, using CAM software, or through computer-aided programming, with automated systems enhancing efficiency and accuracy by optimizing the machining process.

Programming technology of CNC milling-turning composite machine tool

The CNC turning and milling composite machine combines both processes, using programming to perform complex tasks. Effective CNC programming technology not only improves machining accuracy but also optimizes machining efficiency and reduces production costs. This will detail the CNC programming language, common instructions, path planning optimization, and programming optimization methods.

1. Types and characteristics of CNC programming language

CNC programming language is an important part of CNC mill-turn composite machine tool programming. Common CNC programming languages include ISO, G code, M code, custom macros, and high-level languages. Each programming language has its specific use and characteristics:

ISO Programming Language

ISO is an international standard CNC programming language used to control machine tool motion, speed, and parameters. Its simple operation and easy-to-understand code make it suitable for beginners.

G Code

G code is the most commonly used instruction set in CNC programming for controlling machine movement during machining. It includes control of basic elements such as coordinate system, feed speed, tool radius, etc. It has high precision and control capability and is widely used in CNC machine tool processing.

M code

M code controls additional CNC functions like start, stop, tool change, and coolant. It enhances the functionality of the machine tool and is an integral part of CNC programming.

Custom Macro Programs

A custom macro program is a reusable program that significantly improves programming efficiency and reduces repetitive work through modular programming.

High-Level Languages

High-level languages (e.g., CNC control programs, programmable controllers) enable more flexible, complex CNC machine programming.

2. Analysis and application of common commands in CNC programming

In CNC programming, common instructions include linear instructions, arc instructions,s, and hole machining instructions. Each instruction has a specific format and application scenario:

Linear Instruction

The straight line instruction (e.g. G01 XYY ZZZ F_) is used for straight line machining, where G01 indicates straight line interpolation, XYY ZZZ indicates the end point coordinates of the straight line, and F_ indicates the feed rate of machining. This instruction is widely used for straight-line contour machining.

Arc Instruction

Arc instruction is used for curve machining, which can accurately control the start, end, and radius of an arc in CNC machining. By reasonably setting the parameters of the arc, the problems of machining error and excessive cutting load can be avoided.

Hole Processing Instruction

Hole machining instructions control drilling, milling, and other equipment for hole operations. Setting appropriate parameters based on material and requirements improves efficiency and ensures quality.

3. Command setting and path planning optimization

When writing instructions, you need to reasonably set the machining parameters, such as feed rate, depth of cut, tool selection, etc., to ensure machining accuracy and efficiency. In addition, path planning is also critical, reasonable path design can not only improve machining efficiency but also reduce tool wear and machine burden, reducing machining errors.

4. Optimization methods of CNC programming technology

To improve the efficiency and machining accuracy of CNC programming, the following optimization methods can be taken:

Switching coordinate system optimization

In CNC machining, switching different coordinate systems (such as workpiece coordinate system, and machine coordinate system) is a common operation. To improve efficiency, minimize coordinate system switches and ensure accuracy is maintained to avoid machining errors.

Optimization of machining tool paths

Reducing the movement path of the tool is an effective means of improving machining efficiency. Optimizing the machining strategy and tool path design reduces empty walks and repetitive movements, enhancing efficiency.

Optimization of machining parameters

Reasonable machining parameter settings have an important impact on machining accuracy and efficiency. Adjusting machining parameters based on material properties ensures process stability and efficiency.

Optimization of the machining process

In addition to programming itself, the entire machining process needs to be optimized. Check the workpiece and tool condition before machining to ensure they meet requirements; maintain chip cleaning and hydraulic oil temperature control during machining for stability and reliability.

Optimization of programming technology of CNC mill-turn compound machine tool

As demand for high-efficiency, high-precision machining grows, CNC milling and turning composite machine tool programming is increasingly used in manufacturing. It enhances processing efficiency and quality while driving industry advancement toward intelligence and automation. Future innovations and challenges will focus on improving production efficiency and addressing new material processing and automation needs, significantly impacting the manufacturing sector.

1. CNC milling and turning machine tool programming technology in the application of machinery manufacturing

CNC turning and milling composite machine tool programming is increasingly used in machinery manufacturing, mainly in the following aspects:

Efficient processing methods

CNC turning and milling composite machine tool programming offers a more flexible and efficient processing method than traditional manual or mold processing. Through CNC programming, the manufacturing process is digitalized, informative, and intelligent, significantly improving the degree of automation in manufacturing.

Improve machining accuracy and quality

CNC turning and milling composite programming enables precise, complex processing, improving part accuracy and product quality, especially in engraving, while reducing manual errors and waste.

Reducing Human Operational Errors

CNC programming minimizes human error, ensuring stability and accuracy, especially for complex mechanical products.

Reduce Costs

CNC turning and milling compound machines reduce labor costs and errors, lowering manufacturing costs.

2. The development trend of CNC turning and milling machine tool programming technology

With the intensification of industrial manufacturing competition, CNC milling machine tool programming technology is facing new challenges and development opportunities. The future development trend is mainly reflected in the following aspects:

Improve production efficiency and product quality

.With the intensification of global competition, manufacturing enterprises are increasingly focusing on improving production efficiency and reducing production costs. CNC milling and turning machines improve production efficiency, ensuring high precision and high-efficiency processing, boosting enterprise competitiveness.

Responds to the machining needs of new materials

New materials have higher hardness, toughness, and rigidity, and traditional machining methods often difficult to cope with these requirements. CNC mill-turn machines quickly and accurately process new materials using advanced programming to meet modern manufacturing standards.

Automation Development

The automation level of CNC turning and milling compound machine tools will continue to improve. Robot and vision technologies will make machine tools smarter, reduce manual intervention, and enhance efficiency and quality.

Technological innovation

With technological advancements, CNC turning and milling composite machine tool programming will become more automated and intelligent, driving the manufacturing industry toward greater efficiency, accuracy, and flexibility.

3. CNC milling machine tool programming technology application trends

Future research and applications in CNC turning and milling composite machine tool programming will focus on continuous optimization in the following key areas:

High-efficiency improvement

Optimizing program design and improving motion paths can significantly boost the productivity of CNC turning and milling machines. For example, additive manufacturing with the help of advanced algorithms and computer technology can accelerate the machining process. AI and machine learning will optimize programming, reduce human error, and improve efficiency.

Intelligent Development

Machine learning, voice recognition,n, and other technologies will significantly improve the level of intelligence of CNC milling and turning machines. Machine learning optimizes machining strategies by analyzing data, while voice recognition allows operators to control machines with voice commands, improving convenience and accuracy.

Increased Flexibility

CNC mill-turn machine programming will focus on flexibility, enabling a wide range of tasks through modular design and improved interfaces for faster, more efficient operation.

Conclusion

The future development direction of CNC mill-turn programming technology is intelligence, precision, and automation. Future research will focus on precision control technology, big data technology, and intelligent programming technology. These studies are expected to provide strong technical support for the development of CNC turning and milling compound machines.

What is CNC mill-turn programming technology, and why is it important?

CNC mill-turn programming technology enables a single machine to perform both milling and turning operations, integrating multiple machining processes to enhance precision, efficiency, and automation. It plays a critical role in modern manufacturing, especially for complex, high-precision parts used in aerospace, automotive, and mold industries. Effective mill-turn programming reduces setup time, minimizes human error, and improves overall productivity.

Why is programming technology the main bottleneck in CNC mill-turn machining?

Despite the availability of many CAM systems, most lack full support for compound mill-turn operations, making programming complex and time-consuming. Many programs still require manual integration by skilled technicians, limiting efficiency. The main challenge lies in coordinating multiple axes, optimizing tool paths, and managing synchronization between milling and turning processes.

What are the main characteristics of CNC mill-turn composite machine tools?

CNC mill-turn machines feature high integration, multi-axis control, and wide applicability. They can complete several operations—turning, milling, drilling, and tapping—on a single setup, reducing repositioning and clamping errors. These machines are widely used in aerospace, automotive, mold, and energy industries for their speed, accuracy, and versatility.

How does CNC programming technology work in mill-turn machines?

CNC programming technology controls the machine’s movements through mathematical modeling, language specification, and program generation. The program defines machining paths, feed rates, and parameters using standardized G codes and M codes. This ensures the machine follows precise commands to produce accurate, repeatable results.

What programming languages are commonly used in CNC mill-turn machines?

The most common CNC programming languages include:

G Code: Controls cutting actions and motion paths.

M Code: Manages auxiliary functions such as coolant, spindle, and tool changes.

ISO Language: Standardized for global compatibility and readability.

Custom Macros: Automate repetitive tasks and improve programming efficiency.

High-Level Languages: Enable flexible and intelligent machine control through automation and logic.

What are the key steps in optimizing CNC mill-turn programming?

Optimization focuses on reducing tool path length, minimizing coordinate system switches, and adjusting cutting parameters. By improving feed rates, tool selection, and motion strategies, programmers can enhance machining accuracy, reduce tool wear, and achieve smoother operations. Efficient path planning also prevents idle movements and reduces cycle time.

What are the benefits of CNC mill-turn programming in modern manufacturing?

CNC mill-turn programming enables high automation, precision, and flexibility in production. It helps manufacturers reduce labor costs, minimize manual errors, and deliver consistent product quality. The technology supports digitalized and intelligent manufacturing, essential for industries pursuing Industry 4.0 and smart factory goals.

What challenges exist in manual CNC mill-turn programming?

Manual programming requires extensive experience in C-axis coordination, multi-axis path design, and error management. It is labor-intensive and prone to mistakes if synchronization or thermal deformation is not properly handled. As a result, automated and intelligent programming systems are being developed to replace purely manual methods.

How is CNC mill-turn programming evolving with new technologies?

CNC programming is rapidly advancing toward intelligence, automation, and precision control. Future systems will use AI, big data analytics, and machine learning to optimize tool paths, detect errors in real-time, and adapt machining strategies automatically. Voice control and vision-based automation will also make CNC operation more intuitive and efficient.

What are the future trends in CNC mill-turn machine tool programming technology?

Future development will focus on:

Intelligent automation with AI-driven path optimization.

Higher flexibility through modular and adaptive programming systems.

Advanced precision control for complex materials.

Integration with robotics and digital twins for real-time monitoring and self-correction.

These innovations will drive the next generation of smart, high-performance CNC manufacturing.