Progressive dies shape sheet metal, and a tapping unit can convert die motion into tap rotation for threading holes.

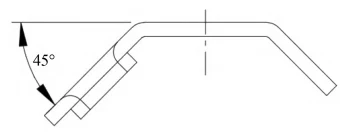

For thicker sheet metal materials, Operators can implement two-step processes—pre-bending followed by bending—to overcome springback during bending.

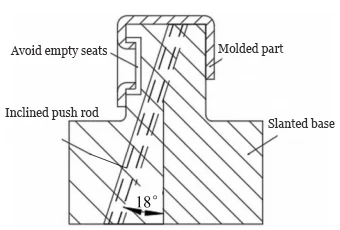

The punch uses a slanting ejector to prevent bent thread holes from locking and to ensure easy release.

Taking a U-shaped sheet metal part as an example, Engineers designed a progressive die based on the above characteristics.

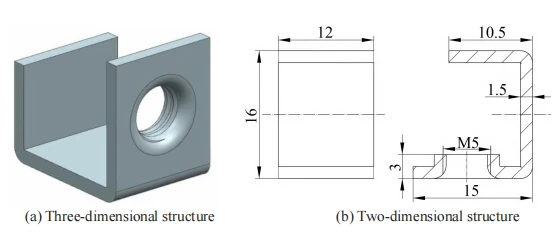

Part Structure Analysis

The sheet metal part is U-shaped with an internal threaded hole on one side, as shown in Figure 1(a).

Measuring 16 × 12 mm with side bends of 15 mm and 10.5 mm, the part is made from SUS304 with a 3 mm flanged hole, an M5 thread, and a 1.5 mm wall thickness (see Fig. 1b).

Forming Process Analysis

The part needs blanking, punching, flanging, bending, and tapping; a single-stage die reduces efficiency.

Small size and positioning issues lead to high scrap rates, prompting engineers to utilize progressive die forming.

The threaded hole needs a tapping unit, and engineers pre-bend and bend to prevent springback.

After flanging and bending, the formed retaining position prevents normal ejection.

The designer requires a slanting ejector structure to facilitate part removal at the flanged area.

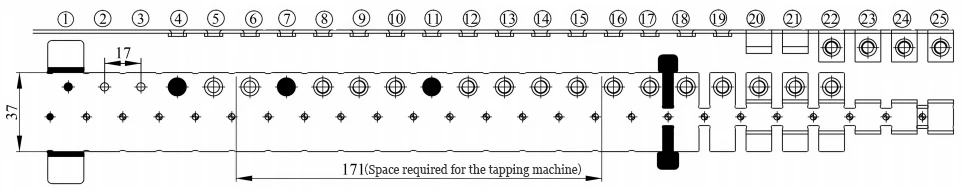

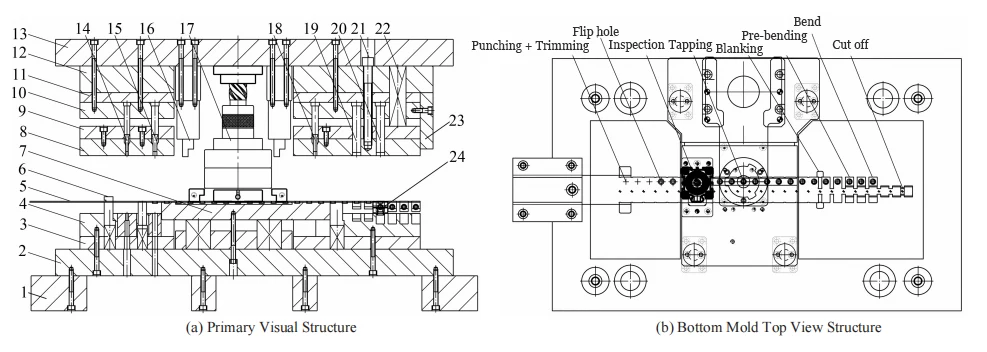

Multiple blanking steps ensure die strength, and engineers arrange 25 operations as shown in Figure 2.

Step ① Punching + Trimming: punch guide and flanged holes, trim strip; holes aid feeding and flanging.

A trimming operation reduces the strip width to 37 mm, the typical scrap width from other products.

Steps ②–③ are idle, so engineers design inserts into the dies during Step ① for the 17 mm pitch.

Engineers use the space of Steps ② and ③ for inserts, designating these steps as idle.

The base hole is countersunk for tapping in ④, while ⑤–⑥ remain idle.

Step ⑦ adds a misfeed detector to alert and pause the press if the countersink or strip is out of specification.

Steps ⑧–⑩ and ⑫–⑯ remain idle; Step ⑪ performs threading using a tapping tool.

Material between adjacent parts is slotted in ⑰, leaving only the strip’s central section.

Steps ⑱–⑲ are idle; Step ⑳ pre-bends thick material 45° to reduce springback and prevent hole interference (Fig. 3).

㉑ remains idle, while ㉒ bends the sheet 90° with an 18° slant punch for smooth hole ejection (Fig. 4).

Steps ㉓–㉔ are idle; Step ㉕ cuts, separating the formed part from the strip and placing it into the collection box.

Tapping Unit Structure Analysis

The part features an internally threaded hole requiring a tapping unit on the progressive die.

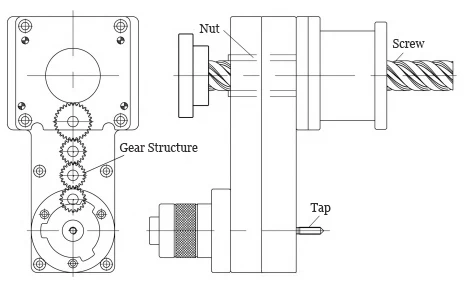

The progressive die’s tapping device converts the upper die’s vertical motion via a screw and gears to rotate the tap (Fig. 5).

Die Structure

A tapping device on the mold converts the upper die’s vertical motion into rotation, enabling internal threading.

The bending punch is inclined to avoid retaining positions from bent holes. The engineers add two shims to the upper die to compensate for the height of the tapping device (Fig. 6).

1. Mold Foot; 2. Lower Mold Base ;3. Lower Mold Spacer; 4. Cavity Die Plate;5. Material Strip; 6. Material Lift Pin; 7. Top Plate; 8. Unloading Plate; 9. Stop Plate; 10. Upper Mold Fixing Plate; 11. Upper Mold Spacer Plate; 12. Spacer plate of the upper mold; 13. Base of the upper mold; 14. Punch Die; 15. Flanging Die; 16. Nitrogen Spring; 17. Tapping Tool; 18.Cutting Die; 19. Pre-bending Die; 20. Bending Die; 21. Limit Screw; 22. Spring; 23. Cutting Die; 24. Tapered Punch Structure.

Conclusion

The engineers install a tapping device in the progressive die based on the U-shaped sheet metal part structure.

The tapping device converts the vertical movement of the upper die into rotational motion, thereby forming internal threads.

For internal thread holes on the bending surface, the stamping sequence involves tapping followed by bending.

To prevent incomplete flanging from die component damage affecting tapping, the engineers install a misfeed detection device before tapping.

Engineers have validated the die through actual production: its structure is rational, and the formed parts meet the requirements.

FAQ:

What is a progressive die and how does it shape sheet metal?

A progressive die is a specialized tool used in stamping that shapes sheet metal through a series of sequential operations, such as blanking, punching, flanging, bending, and tapping. Each station performs a specific task, producing complex parts efficiently and consistently.

How does a tapping unit work in a progressive die?

The tapping unit converts the vertical motion of the upper die into rotational motion using a screw and gears. This allows the formation of internal threads directly on the sheet metal part during production.

Why are two-step bending processes necessary for thicker sheet metal?

Thicker sheet metal tends to spring back after bending. Operators implement pre-bending followed by final bending to control springback, ensuring precise angles and preventing dimensional inaccuracies.

What is the function of a slanting ejector in sheet metal forming?

A slanting ejector prevents bent thread holes from locking within the die, ensuring smooth removal of the formed part and avoiding damage to delicate features like internal threads or flanges.

How does progressive die forming improve efficiency for small-sized parts?

For small parts with positioning challenges, single-stage dies often cause high scrap rates. Progressive dies reduce scrap by performing multiple operations sequentially, increasing precision and overall production efficiency.

What steps are involved in forming a U-shaped sheet metal part with a threaded hole?

The forming sequence includes blanking, punching, flanging, pre-bending, bending, and tapping. Additional measures like trimming, slotting, and inserting idle steps are incorporated to maintain die strength and part quality.

How is a misfeed detection device used in progressive die operations?

A misfeed detector monitors the strip and countersink quality. If the strip misfeeds or the countersink is off-spec, the device alerts and pauses the press, preventing defective parts and die damage.

What design considerations are applied to the bending and tapping sections of the die?

The bending punch is inclined to avoid retaining positions from previous bends, and shims are added to accommodate the tapping unit’s height. This ensures smooth threading and ejection without interference.

How are idle steps utilized in progressive die design?

Idle steps, such as Steps ②–③ or ⑫–⑯, allow space for inserts, misfeed detectors, or die components while not performing active forming. These steps help optimize die strength and maintain proper spacing between operations.

How is the progressive die validated for production use?

Engineers validate the die through actual production runs, checking that the structure is rational, operations function correctly, and the formed parts meet design specifications for dimensions, threads, and flanges.