Table of Contents

The processing manufacturing industry has rapidly developed with the rise of AI, digitalization, and information technology.

CNC machining in automotive mold manufacturing boosts efficiency and gives automotive companies a competitive edge.

Processing technology is closely related to automotive mold manufacturing, of which automotive mold is another important foundation.

CNC processing technology plays a key role in modern advanced technology, especially in the manufacturing of automotive machinery molds.

In recent years, as big data and AI have advanced, the automotive industry’s market environment has improved, with a growing focus on manufacturing quality.

National policies support CNC machining technology, boosting automotive machinery mold manufacturing efficiency.

Overview of CNC machining technology

CNC processing technology is an advanced new manufacturing technology, mainly using computer technology to achieve effective control of equipment.

CNC technology has clear advantages over traditional methods, particularly in automation and efficiency, as shown in the following aspects:

a. Computer information technology: computer program coding is an important basis for the application of CNC processing technology.

After completing the coding program, it is necessary to comprehensively analyze the material and size of the processing components and other information.

Intelligent and automated machining uses application programs to collect data, supporting flexible manufacturing systems.

b. CNC machine tools and mechanical equipment: CNC machine tools are the important core of CNC machining technology, and their application can maximize the savings of human resources and costs compared with traditional technology.

By inputting mold parameters into the CNC machine and using sensors to identify the data, production becomes intelligent and automated.

Computer programming and CNC machine tools are key components of CNC machining technology, working together to form a cohesive system.

CNC automotive machinery mold processing features

1. Reduce processing errors

In automotive mold processing, CNC machining uses computer programs to set relevant data, improving mold accuracy and part matching.

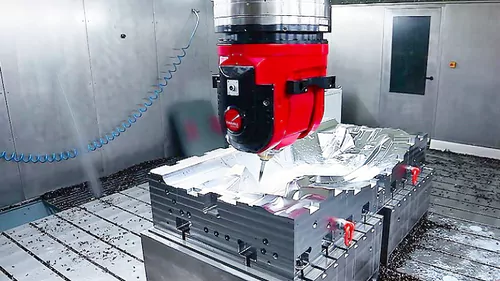

Figure 1 illustrates the principle of CNC mechanical mold processing.

Compared to traditional methods, CNC technology minimizes error values, ensuring mold parts meet design requirements.

This improves mold quality and reduces part errors. The figure shows the CNC mold processing characteristics.

CNC machinery mold processing principle

CNC mold processing features

2. High production efficiency

CNC processing technology is faster and more convenient than traditional methods, effectively reducing mold production time.

CNC technology shortens production cycles, enhances mold quality and efficiency, and reduces costs, providing affordable, high-quality products for the automotive market.

This efficiency improvement enables enterprises to gain a greater advantage in market competition, providing ample space for subsequent development.

CNC automotive mold processing uses computer programs for control, unaffected by external factors.

This ensures stable quality and efficient mold production. Therefore, CNC technology greatly improves production efficiency and product quality.

3. Identifying errors in advance helps avoid unnecessary losses

The use of auxiliary software in CNC machining for automotive mold manufacturing has become highly developed and convenient.

CNC software enhances the accuracy and precision of machinery mold production.

This software can proactively identify potential errors, enabling early detection and resolution of processing issues.

In automotive machinery mold manufacturing, all kinds of errors often occur, seriously affecting product quality and leading to defects.

The use of CNC technology-assisted software can not only minimize or avoid errors, and reduce unnecessary losses, but also improve production efficiency.

CNC technology ensures quick product processing and high reliability through precise mold quality control.

The importance of CNC processing technology in automotive mold manufacturing

1. Conducive to enhance the intelligent manufacturing and development of automotive molds

Intelligent production can be reflected in all aspects of the enterprise, such as in intelligent management.

To realize intelligent management, enterprises need to introduce electronic management systems that visualize and data-enable the management process.

Cloud platforms manage intelligent production, overseeing production status and quality. They update material orders in real-time to optimize storage and distribution.

In automotive mold manufacturing, CNC technology enhances machine tool intelligence and integrates it into the entire production process, driving product development.

The intelligent upgrade of machine tools mainly reflects product intelligence, such as the use of i5 intelligent machine tools.

Machine tools are key in automotive mold manufacturing.

The introduction of intelligence improves production line efficiency, increasing the use of intelligent machine tools.

CNC machining technology boosts the intelligence of automotive mold manufacturing and enhances industry quality and productivity.

CNC technology in automotive mold manufacturing promotes emerging industries’ growth and the integration of real and digital economies.

It creates a platform for domestic and foreign cooperation, leading to industry-wide upgrades.

2. Beneficial to enhance the precision of automotive mold manufacturing

In automotive mold manufacturing, part accuracy requirements are extremely high, with mold tolerance controlled within 1/5 or 1/10, especially for mold components.

In practice, lack of safety awareness and irregular operations often cause issues. These lead to safety hazards and poor-quality production by inexperienced personnel.

With the popularization and application of CNC machining technology, these problems have improved significantly.

CNC technology enhances machining accuracy, and consistency, and reduces human error in production.

CNC machining enhances the precision and quality of automotive mold manufacturing, ensuring products meet strict standards.

3. Beneficial to realize the automation of automobile mold manufacturing

CNC machining uses computer control to simplify operations and enable automated production.

CNC processing is a highly automated production mode that requires the pre-setting of equipment parameters in the computer system.

Automated production of automotive molds represents a breakthrough in automotive manufacturing.

It changes production modes, reduces human error, and lowers labor costs.

Improving automation in automotive machinery mold manufacturing lays a solid foundation for the development of intelligence and automation.

This promotion of automation helps to realize the continuous production of automobile machinery molds, and further improve the productivity of automobile manufacturing enterprises.

4. Favorable to improve the overall productivity of enterprises

In market competition, enterprises must focus on improving production efficiency and reducing costs, all of which depend on ensuring product quality.

Therefore, constantly improving the productivity and quality of products is the key to the sustainable development of enterprises.

Improving production efficiency and quality can also reduce the enterprise’s production costs.

In the production and manufacturing of automotive machinery mold, the application of CNC machining technology significantly improves the overall production efficiency of the mold.

This technology not only reduces the negative impact of improper manual operation but also reduces the errors in the production process, making the production process smoother.

Optimizing the production process with CNC technology boosts efficiency, enhances competitiveness, and supports sustainable development.

5. Conducive to enhance the standardization of mold manufacturing

There are many kinds of automobile molds, and all kinds of molds in materials, forms, and characteristics of significant differences, especially in the form of structure are different.

As mold is usually a single piece of production, rather than mass production, it is difficult to achieve the same situation in the manufacturing process.

In CNC automotive mold manufacturing, enterprises must strictly follow the relevant standards and norms, and scientific and reasonable manufacturing work.

This standardized operation process not only helps to ensure the consistency of product quality but also improves production efficiency and reduces production costs.

By improving the standardized manufacturing level of the mold, enterprises can better respond to changes in market demand and enhance their competitiveness in the industry.

CNC machining technology in automotive mold manufacturing application strategy

1. Electrolysis technology in the application of automotive mold manufacturing

To better utilize CNC machining technology, the automobile manufacturing industry should combine electrolysis technology.

Electrolysis technology is a new CNC machining method. It immerses metal in electrolyte and dissolves it through ionization, accelerating automotive mold formation.

This technology can realize ten times the traditional EDM technology in terms of production hourly speed, and the effect is more significant.

In the electrolysis process, there are fewer cutting conditions, so manufacturers often use electrolysis technology to make complex molds.

The application of electrolytic technology in automotive machinery manufacturing needs to strictly control the quality and performance of raw materials to ensure the quality of the final product, and to enhance the precision of CNC machining manufacturing.

This combination not only improves production efficiency but also provides higher flexibility and precision for mold manufacturing.

2. The application of ultrasonic technology in automotive mold manufacturing

In automotive machinery mold manufacturing, integrating ultrasonic technology with CNC processing technology for joint application can improve efficiency.

Ultrasonic processing technology uses ultrasonic waves to produce ultrasonic frequency vibration and power, through the abrasive striking effect, so that the automobile mold achieves the expected shape.

In conventional automobile machinery mold manufacturing, manufacturers mainly use ultrasonic technology in “semiconductor materials,” “conductive materials,” and “non-conductive materials,” especially in brittle material molds.

Processing, its effect is more significant.

The introduction of ultrasonic technology not only improves machining accuracy but also reduces damage to brittle materials, thus providing greater flexibility and efficiency in mold manufacturing.

The application of this technology provides a new solution for the production of complex shapes and high-precision molds.

3. Application of high-pressure water-cutting technology in automotive mold manufacturing

In automotive mold manufacturing, high-pressure water-cutting technology is an advanced technology for processing and manufacturing molds through the kinetic energy and pressure of water.

The technology uses jets to cut mold material by continuously pressurizing water flow.

High-pressure water becomes supersonic, enabling efficient cutting and optimizing the mold.

High-pressure water-cutting technology offers many benefits: no heat-affected zone, minimal material loss, and high cutting accuracy.

It’s ideal for processing complex mold shapes and fine details.

In addition, the technology is effective on a wide range of materials, such as metals, plastics, and composites, making it widely used in modern automotive mold manufacturing.

Through high-pressure water cutting technology, manufacturers can improve the efficiency and quality of mold processing, while reducing the impact on the environment.

4. Strengthen the control of spindle rotation of CNC machine tools

Once the automotive mold design is complete, enter the CNC mold manufacturing stage. At this point, CNC machine tools mainly affect mold quality.

The correct placement and positioning of the mold depends directly on the rotation of the machine tool spindle.

If the spindle has problems in the rotation process, it will lead to a reduction in the precision of the mold in the manufacturing process.

Therefore, in the mold manufacturing process, the staff needs to strictly control the rotation of the spindle of the CNC machine tool.

This includes regularly checking the balance, alignment, and lubrication status of the spindle to ensure its stability and accuracy.

In addition, real-time monitoring of the spindle’s operating status and timely adjustment of the rotation speed and direction can further improve the precision and quality of mold manufacturing.

Strengthening the control of spindle rotation, can effectively reduce processing errors and improve the overall productivity of automotive mold.

5. Strengthen the control of CNC machine tool processing temperature and strength

In the application of CNC technology in the process of mold manufacturing, processing strength temperature, and other factors directly affect the precision and quality of the mold.

If you fail to correctly adjust the position of the mold in the mold processing, it may lead to a reduction in precision and quality.

During machining, control CNC machine tool strength and temperature strictly.

This prevents quality issues like mold deformation, fracture, and distortion, maximizing automotive mold precision.

Especially on CNC machine tools, the tool is prone to frictional heat generation at high temperatures, which will lead to changes in the contact surface between the tool and the mold, seriously affecting the accuracy of the overall process.

Therefore, for the specific conditions of mold production, we should select suitable tools and further optimize the cutting depth and size.

Applying cooling lubricants effectively lowers temperature, reducing heat impact on tools and molds.

This ensures high precision and quality in mold manufacturing.

6. Repeated inspection of CNC automobile machinery molds

In the production of automotive machinery molds, even a small error will have a significant impact on the precision and quality of the mold.

Therefore, in the production process of CNC automobile machinery mold, must strengthen the control of accuracy, to minimize human error, to avoid the waste of resources and energy caused by improper operation.

Throughout production, personnel should conduct repeated inspections of the automotive mold. Necessary adjustments based on results ensure the mold meets quality standards.

Following multiple tests and inspections is essential for understanding CNC requirements for automotive machinery molds and machine tools.

This approach reduces processing errors and improves production accuracy to the maximum extent.

By establishing a strict inspection mechanism and feedback process, we can effectively improve the quality and efficiency of the entire mold production.

The actual case of automobile mold CNC machining technology

We analyze the case of CNC machining for automobile cover part molds and study its processing engineering to understand and summarize methods for improving the processing of automobile cover part molds.

In stretching mold CNC machining, technicians must fully consider the concave die, convex die, and crimp ring CNC content. Other technologies can be completed on the milling machine or programmed by the technicians.

For example, the convex mold CNC machining process needs to consider its performance requirements; in the convex mold profile CNC machining, where the feed parameters for 100 mm/min, spindle parameters 400 r / min, the implementation of all aspects of the processing, embodied in.

a. Preventing a sudden increase in the surface allowance during the machining of the profile, which would otherwise result in damage to the tool;

b. To address the problem of the junction margin that a large tool cannot remove from the surface, we use a small tool to handle it and meet the product accuracy requirements.

After analysis, it’s clear that refining the existing mold map analysis is essential in actual mold CNC machining.

Understanding the design map fully and applying CNC machining technology scientifically and reasonably is also crucial.

This approach meets machining program requirements, enhancing CNC machining quality and reducing large-scale repairs.

It holds great significance for the development of automotive mold CNC machining technology.

Conclusion

CNC machining technology in automotive machinery mold manufacturing is a breakthrough in traditional technology, but also the reform and innovation of traditional technology.

Applying CNC machining technology improves automotive mold production quality and enhances production efficiency.

This ensures the automotive industry’s economic and social benefits develop synergistically.

At the same time, in CNC machining, from programming to processing the overall production process needs to be strictly by the corresponding operation and standardization.

We can see that applying CNC technology scientifically and rationally promotes the harmonious and stable development of enterprises, which is an important prerequisite.