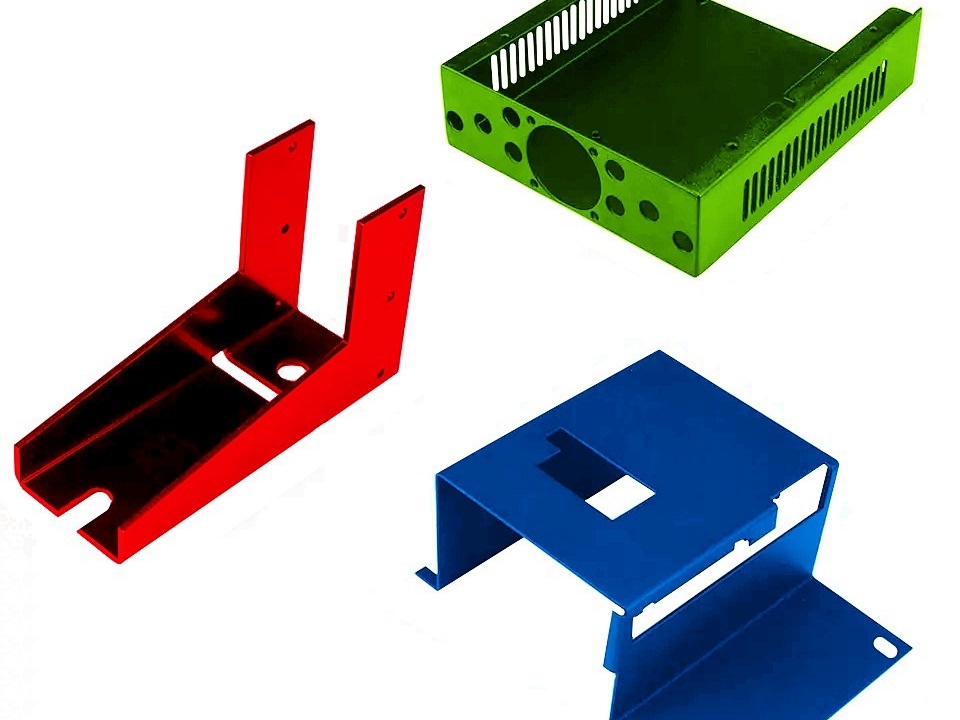

CNC Sheet Metal Processing:Key Considertions and Best Practices

CNC sheet metal processing is an advanced manufacturing method with significant potential. It is gaining popularity for creating high-quality sheet metal parts. To ensure precision and efficiency, manufacturers must pay attention to specific practices. Below are the essential points for success in CNC sheet metal processing.

Developing an Effective Processing Route

An efficient processing route is crucial for achieving excellent results. Use the following steps to establish a proper workflow:

Process the Reference Surface First

Create an accurate reference surface before proceeding. This step ensures the precision of all subsequent operations.

Divide the Processing Stages

Organize the workflow into three phases: roughing, semi-finishing, and finishing. This segmentation ensures consistent quality and allows early detection of issues.

Prioritize Hole Processing

Start by machining holes for parts like boxes, brackets, and connecting rods. This step ensures alignment and improves precision. It also simplifies later machining operations.

Innovative CNC Sheet Metal Processing Technologies

Manufacturers enhance CNC sheet metal processing through advanced technologies. These innovations improve accuracy and flexibility.

Laser Shock Technology

A pulsed laser beam impacts the metal surface to create a plane wave. This wave causes plastic deformation, improving material properties and surface quality.

Plastic Forming Technology

This approach involves three types of plasticity:

Fine-grain plasticity is the most common. It works best with materials that have high thermal stability and fine-grained structures.

Phase-change plasticity is suitable for applications involving phase transformations.

Other plasticity methods are used based on specific material properties.

Hydraulic Forming Technology

This technique uses a hydraulic bladder as a mold, with oil as the pressure medium. It allows for precise shaping of complex designs while preserving material integrity.

Operational Guidelines for CNC Sheet Metal Processing

To achieve high-quality results, follow these operational tips:

Review Drawings Thoroughly

Verify all details, including bending directions, material type, plate thickness, and dimensions, before starting.

Ensure Surface Cleanliness

Clean the workpieces carefully, especially before electroplating. Address defects promptly to maintain quality.

Inspect Workpiece Quality

Check for defects that could affect further processing. If issues arise, resolve them before proceeding.

Perform Post-Processing Inspections

Conduct final quality checks to ensure the product meets all specifications. Address any remaining issues immediately.

Welding Best Practices for CNC Sheet Metal Processing

Welding is a vital part of CNC sheet metal fabrication. Proper welding techniques ensure strong and accurate assemblies.

Prepare Welding Tools and Supplies

Inspect welding equipment, rods, and protective gear. Ensure they meet safety and performance standards.

Clean the Weldment

Remove rust, grease, and moisture from the weldment. Clean surfaces improve weld strength and reliability.

Design Appropriate Bevels

Use suitable bevel designs to maintain dimensional accuracy and minimize deformation during welding.

Avoid Continuous Welding for Long Welds

Use intermittent welding to prevent thermal deformation and maintain consistent weld quality.

Advantages of CNC Sheet Metal Processing

CNC sheet metal processing offers several benefits:

High precision ensures components meet exact specifications.

Exceptional flatness enhances both functionality and aesthetics.

Reduced material waste and efficient processes lower production costs.

Automated workflows improve productivity and shorten lead times.

These advantages depend on proper execution and strict quality control throughout the process.

Conclusion

CNC sheet metal processing has revolutionized the fabrication industry with its unmatched precision and efficiency. By following a clear processing route, leveraging advanced technologies, and adhering to operational best practices, manufacturers can maximize the potential of CNC machining. When quality is ensured at every stage, CNC sheet metal processing meets the demands of modern industries and drives innovation.

FAQ:

CNC sheet metal processing is an advanced manufacturing method that uses computer numerical control (CNC) technology to create precise sheet metal parts. It involves various techniques like cutting, bending, welding, and other shaping processes to produce high-quality components.

Developing an effective processing route ensures the smooth flow of operations, minimizes errors, and maximizes precision. It involves organizing the workflow into phases like roughing, semi-finishing, and finishing, which helps detect issues early and ensures consistent quality.

Creating an accurate reference surface before starting any machining operations is crucial for ensuring that all subsequent operations are aligned and precise. This helps avoid errors in later stages of processing.

Advanced technologies like Laser Shock Technology, Plastic Forming Technology, and Hydraulic Forming Technology improve the accuracy and flexibility of CNC sheet metal processing. These innovations enhance material properties and surface quality.

Laser Shock Technology uses a pulsed laser beam to create a plane wave that impacts the metal surface. This wave causes plastic deformation, improving the material properties and surface quality, which results in better overall performance.

Manufacturers should thoroughly review drawings, ensure surface cleanliness, inspect workpiece quality, and conduct post-processing inspections. These steps are vital for maintaining high-quality standards and addressing defects before they impact the final product.

For effective welding, manufacturers should prepare welding tools and supplies, clean the weldment to remove rust or grease, design appropriate bevels, and avoid continuous welding for long welds to prevent thermal deformation.

CNC sheet metal processing offers several benefits, including high precision, exceptional flatness, reduced material waste, efficient processes, and improved productivity. These advantages help reduce production costs and shorten lead times.

Plastic forming technology involves different types of plasticity, such as fine-grain plasticity for materials with high thermal stability and phase-change plasticity for materials undergoing phase transformations. These techniques help shape materials accurately based on their properties.

Clean surfaces are essential for ensuring strong welds, preventing defects, and maintaining high product quality. Cleaning workpieces before processes like electroplating helps achieve better finishes and overall strength.