Injection molding is one of the most widely used manufacturing processes for the mass production of complex plastic parts. It involves melting plastic raw materials in an injection molding machine, then injecting the molten plastic into a mold cavity under high pressure. After cooling and solidification, the plastic takes the shape of the cavity, forming the final product.

What Is an Injection Mold?

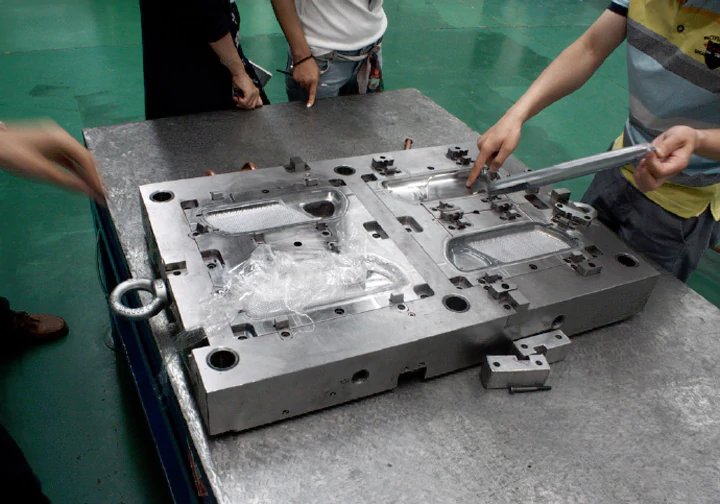

An injection mold typically consists of two main parts:

Moving Mold (Core): Installed on the movable platen of the injection molding machine.

Fixed Mold (Cavity): Mounted on the stationary platen.

During the injection process, the two molds close tightly, forming a sealed cavity and casting system. Once the plastic product has solidified, the mold opens, separating the moving and fixed parts, allowing the finished part to be ejected or removed.

Basic Structure of an Injection Mold

The design of an injection mold depends on several factors, including:

The type of plastic material used

The shape, size, and structure of the product

The specifications of the injection molding machine

Despite these variables, most injection molds share a standard structural layout, consisting of the following main components:

1. Pouring System

Also known as the gating system, this part channels the molten plastic into the mold cavity. It includes the sprue, runners, gates, and sometimes cold wells. Its design directly affects flow efficiency and product quality.

2. Temperature Control System

This system regulates the mold temperature, ensuring even cooling and reducing defects such as warping or sink marks. It typically consists of cooling channels through which water or oil flows.

3. Molding Section

This is the core and cavity area that comes into direct contact with the plastic, defining the final shape and dimensions of the product. It requires high-precision machining and is often made from hardened tool steel for durability.

4. Structural Parts

These components support the mold’s overall frame, maintain alignment, and ensure structural stability and strength during repeated production cycles. Examples include support plates, guide pins, and clamping plates.

Critical Components: Pouring System and Molding Section

Among all the components, the pouring system and molding section are the most critical. These parts are responsible for directly shaping the molten plastic and are subject to high pressure and temperature. As such, they are typically:

Complex in design

Variable depending on part geometry

Machined to high precision tolerances

Their performance directly impacts the quality, accuracy, and consistency of the finished product.

Overview of the Injection Molding Process

The injection molding process can be broken down into the following key steps:

Plasticizing: Plastic granules are heated and melted inside the injection unit.

Injection: The molten plastic is injected into the mold cavity at high pressure.

Holding & Cooling: The material fills the cavity, then cools and solidifies into the desired shape.

Mold Opening: Once the product has cooled sufficiently, the mold opens.

Ejection: The finished plastic part is ejected from the mold cavity.

This process is highly efficient and capable of producing parts with tight tolerances, smooth finishes, and strong mechanical properties.

Conclusion

Injection molding is a powerful manufacturing method known for its precision, repeatability, and scalability. A well-designed injection mold plays a crucial role in ensuring product quality, dimensional accuracy, and production efficiency.

By understanding the basic structure of an injection mold and the injection process itself, manufacturers can optimize part design, reduce costs, and improve overall productivity.

At RUIYI, we specialize in custom mold design and injection molding services tailored to your unique production needs. Let us help you bring your product to life with efficiency and precision.