When performing surface finishes on CNC machined parts, you must consider several factors beyond the technical requirements. These requirements usually appear in part drawings, but some may not be listed directly.

Therefore, you must consider the following factors to ensure machining quality and production efficiency.

Selection of Machining Accuracy and Surface Roughness

Different CNC machining methods can achieve varying machining accuracy and surface roughness levels. Economic machining accuracy refers to the accuracy that helps control costs and improve efficiency within a specific range.

When choosing a machining method, you must select an accuracy range that guarantees quality and meets the part’s cost-effectiveness needs.

Nature of CNC Workpiece Materials

Different materials require different machining methods. For example, harder materials often need more advanced machining techniques to achieve the desired results.

When selecting surface treatment methods, you must consider the material properties of the CNC workpiece, such as hardness, corrosion resistance, toughness, and other characteristics.

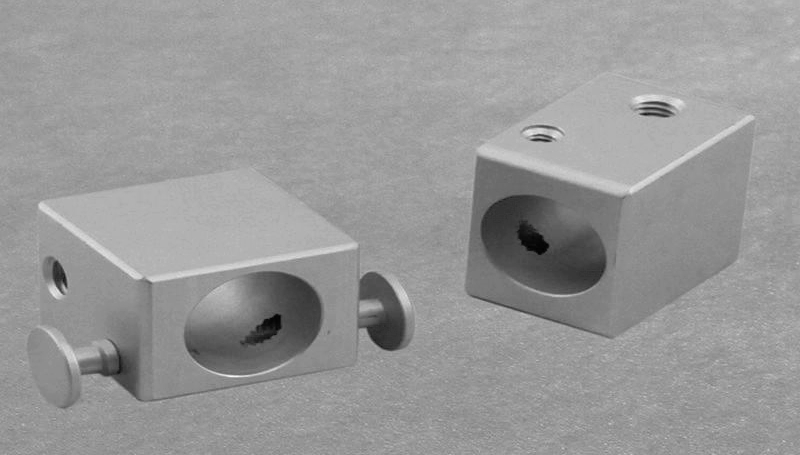

The Structural Shape and Size of the Part

The structural shape and size of the parts directly affect your choice of machining process. Parts with complex shapes usually need more sophisticated machining techniques to achieve high-quality surface finishes. Larger parts may require consideration of the equipment’s processing capacity and the appropriate machining methods.

Balance of Productivity and Economy

In high-volume production, choosing efficient machining processes is critical. You must focus on increasing productivity and reducing the production cost per piece.

This may involve changing how the blanks are made and reducing the labor required in machining to improve productivity.

Existing Equipment and Technical Conditions of the Factory

The condition of the existing equipment is crucial when selecting machining methods. You should mfully utilizethe factory’s existing equipment to explore its potential and improve productivity.

At the same time, you should consider continuously improving existing processing methods and equipment. You can also adopt new technologies to enhance the overall level of technology.