Casting mold is a common process in industrial manufacturing. Baidu Encyclopedia explains that to obtain the structural shape of the part, the structural shape of the part is made of other easily moldable materials in advance, and then the mold is placed in the sand mold. A cavity having the same size as the structure of the part is formed, and a fluid liquid is poured into the cavity. After the liquid is cooled and solidified, a part having the same shape as the mold structure can be formed.

So what are the types of casting molds?

1. Forging forming dies: Forging is the same as casting, which is the most common processing technology for producing parts and components. Forging dies mainly include: forging dies for large presses, forging dies for screw presses, forging dies for flat forging machines, Roll forging dies, etc. At the same time, fastener cold heading dies, extrusion dies, wire drawing dies, liquid forging dies, etc. also belong to forging dies.

2. Stamping dies: Also known as stamping dies, stamping dies are used in cold stamping to process materials to obtain process equipment for parts. This type of mold mainly includes punching dies, bending dies, deep drawing dies, single process dies, composite dies, progressive dies, and automotive cover dies, combined dies, motor silicon steel sheet dies.

3. Plastic molding mold: Due to the widespread application of plastic in life, plastic molding is also a very common processing material in the industrial field. So to process plastic, in the mold, there are plastic molding molds: compression molding molds, extrusion molds, injection molds, thermosetting plastic injection molds, extrusion molding molds foam molding molds, low-tool tool bubble injection molding molds, and Blow molding dies are all plastic molding dies.

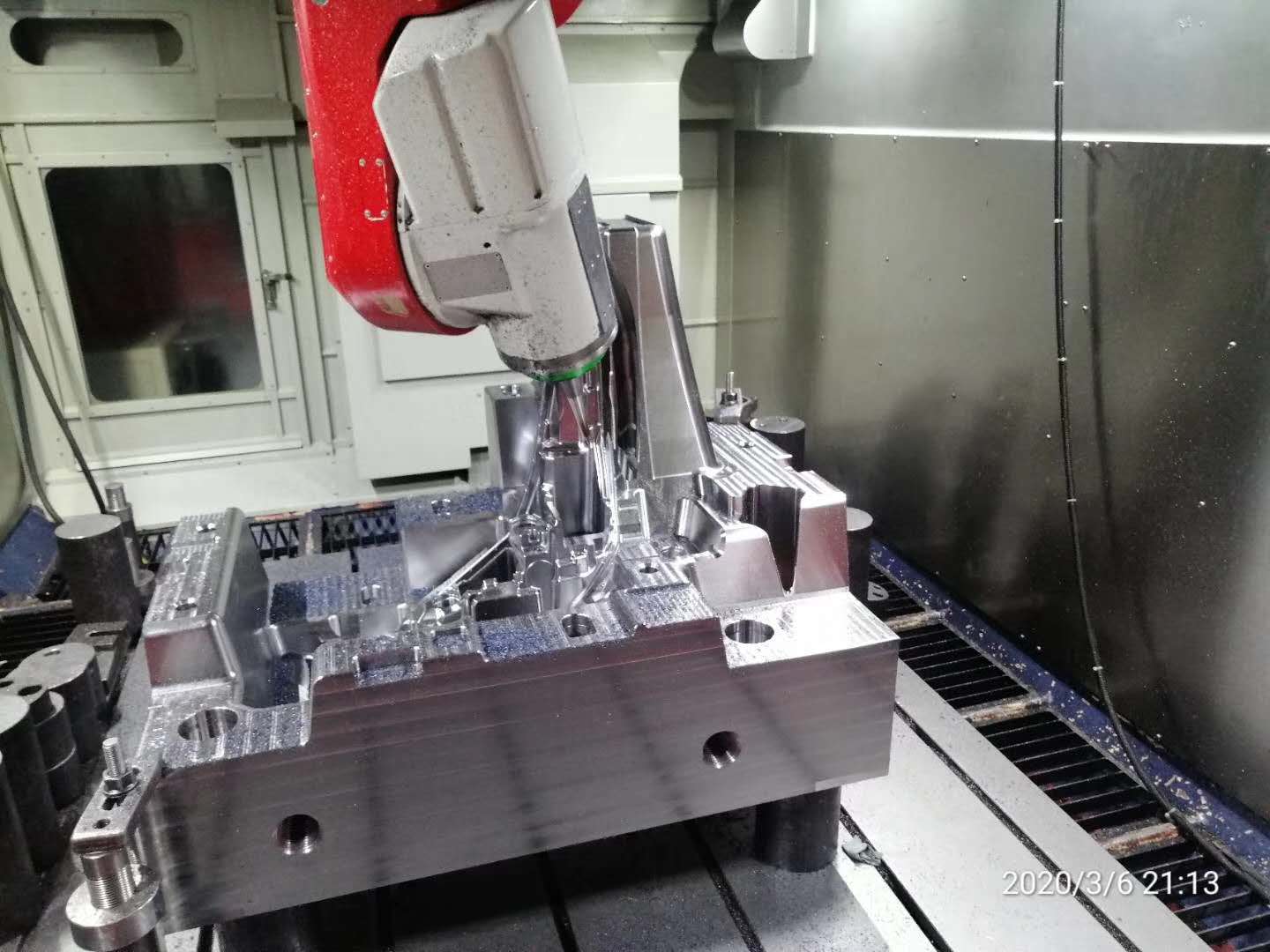

4. Metal molds for casting: This type of mold has certain similarities with die-casting molds, but it is more focused on casting, a metal model used in the casting of various metal parts.

5. Die-casting molds: Castings are one of the more common types of components in production and processing. The die-casting molds mainly include die-casting molds for hot chamber die-casting machines, horizontal cold-chamber die-casting machines, vertical cold-chamber die-casting machines casting molds for full vertical die-casting machines, non-ferrous metal die casting, ferrous metal die casting die.

6. Powder metallurgy mold forming molds: The powder metallurgy mold forming molds are relatively complicated, mainly including manual molds, mobile molds, one-way sets of sleeves, two-way dies, sets of floating dies, and shaping dies. Among these types, there are subordinate classifications. Among them, manual molds also include: radial plastic molds, full plastic molds with outer step sleeves, plastic molds with spherical surfaces, and the like.

7. Molds for glass products: The molds for glass products are mainly classified according to the processing form. The former are forming bottles and can mold, and the latter are forming bottles and can molds, and glassware molds.

8. Rubber molding molds: At this time, rubber processing molds mainly include rubber molds, extrusion molds, and injection molds.

9. Ceramic molds: forming metal molds for various ceramic utensils and other products.

10. Economic mold (simple mold): This is also a processing mold commonly used by some small enterprises, because it is economical, so it is welcomed by everyone. This type of mold mainly includes: low melting point alloy forming mold, thin plate die, laminated die, silicone rubber die, epoxy resin die, ceramic precision casting die, etc.

The above are the types of common casting molds. Casting molds is an important part of industrial manufacturing, and it is indispensable for mass production of products.