The Power of 3D Printing

Imagine chocolate as “ink.” 3D printing transforms ordinary materials into unique, intricate designs. It starts with flat image printing, builds layers, and forms a three-dimensional masterpiece.

This simple application highlights the technology’s potential for personalization and innovation.

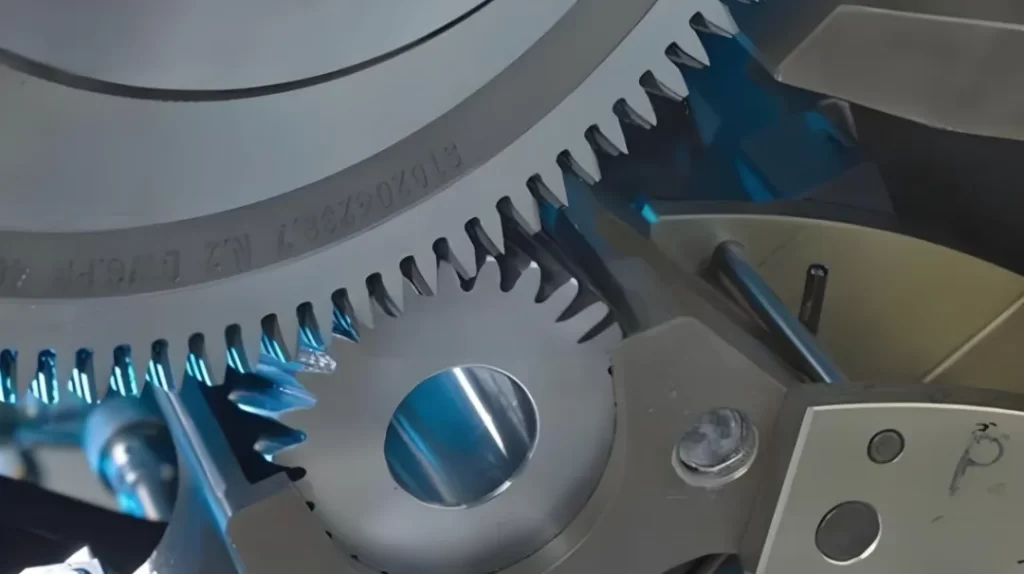

China has developed 3D printing technology for over 30 years. This technology enables manufacturers to create highly complex structures with precision.

However, large-scale manufacturing rarely uses 3D printing due to limitations in speed, cost, and material performance. These factors restrict its applications to specific niche fields.

Challenges and Key Materials

1、Three Main Issues Hindering Large-Scale 3D Printing

Despite its potential, 3D printing faces several obstacles preventing widespread industrial adoption:

Production Efficiency: Current printing speeds are too slow for mass production.

Cost: High material and operational costs limit large-scale applications.

Material Performance: A lack of versatile and durable materials restricts functionality.

2、Types of 3D Printing Polymers

3D printing polymers are classified into two main categories:

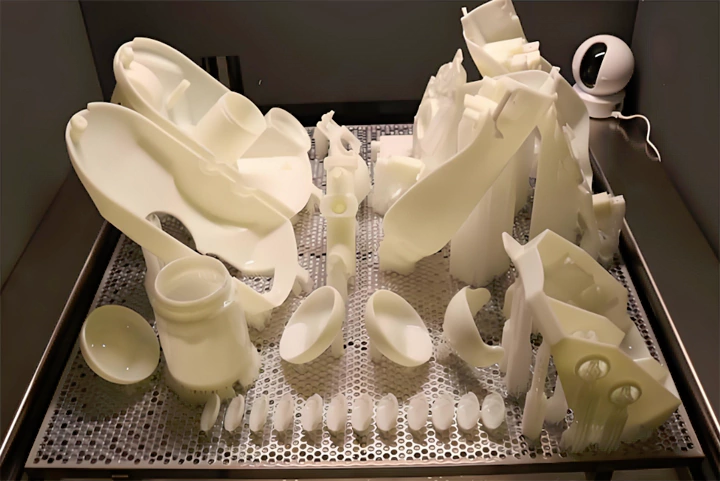

Thermoplastic Materials: These materials soften when heated and solidify when cooled. They are processed using methods like fused deposition modeling (FDM) and selective laser sintering (SLS).

Thermosetting Materials: These materials harden permanently through chemical reactions, providing high strength but limiting processing flexibility.

Overview of FDM and SLS Technologies

1、Fused Deposition Modeling (FDM)

FDM is one of the most common 3D printing techniques. It works by extruding molten thermoplastic materials in a controlled manner, similar to squeezing toothpaste. The material solidifies layer by layer to form the final shape.

While FDM is widely used for prototyping, its point-by-point deposition method makes it slow and inefficient for mass production.

2、Selective Laser Sintering (SLS)

SLS uses a laser to fuse powdered material into solid structures. It provides better precision than FDM, but its high cost and relatively slow speed make it impractical for large-scale manufacturing.

DLP: A Breakthrough in 3D Printing Speed

1、How Digital Light Processing (DLP) Works

Unlike FDM and SLS, which form objects point by point, DLP prints entire layers at once, dramatically improving speed and efficiency.

Manufacturers use low-viscosity liquid monomers in DLP printing. The fluidity of these materials, combined with surface oxygen inhibition, allows for rapid curing.

For instance, some DLP systems can print molds up to 73 cm in height in just one hour—a speed far superior to FDM, SLS, and SLA technologies.

2、Bridging the Gap Between Thermosetting and Thermoplastic Processing

Traditionally, DLP worked mainly with thermosetting resins. However, modern DLP technology can now process thermoplastic polymers at high speeds, expanding its range of applications and making it a more viable industrial solution.

Applications and Benefits of 3D Printing

1、Key Application Areas

3D printing enables digital designs to be transformed into physical products, making it invaluable in fields such as:

Medical Equipment: Custom prosthetics, implants, and surgical tools.

Aerospace: Lightweight, complex aircraft and spacecraft components.

Energy Systems: Optimized parts for renewable energy solutions.

Soft Robotics: Flexible and precise robotic components.

2、Unique Advantages Over Traditional Manufacturing

Compared to conventional production methods, 3D printing offers:

Customization: Enables on-demand, tailor-made designs without the need for expensive tooling.

Faster Iteration: Designs can be modified and reprinted quickly for continuous improvements.

Cost Efficiency: Complex geometries can be manufactured without significant cost increases.

Sustainability: Minimizes material waste and energy consumption.

The Future of 3D Printing

1、Transforming Modern Manufacturing

As printing speed increases, material diversity expands, and costs decrease, 3D printing is set to revolutionize manufacturing.

The combination of customization, precision, and scalability will make it an essential tool in a variety of industries.

2、Redefining Production Processes

Advancements in automation, AI integration, and high-performance materials will push 3D printing toward large-scale, efficient, and highly tailored manufacturing, unlocking new possibilities for industrial production.

FAQ:

3D printing is a technology that builds objects layer by layer from digital designs, using materials like plastic, resin, or metal. It allows for highly customized and complex shapes.

Three main challenges limit mass adoption: slow production speed, high material and operational costs, and limitations in the performance of available materials.

3D printing uses thermoplastics (which melt and re-solidify) and thermosetting materials (which permanently harden through chemical reactions).

FDM extrudes melted thermoplastic materials layer by layer, similar to squeezing toothpaste. It’s popular for prototypes but too slow for mass production.

SLS uses lasers to fuse powdered materials into solid forms. It offers higher precision than FDM but is also more expensive and slow.

DLP prints entire layers at once using light to cure liquid resins, making it much faster than FDM or SLS. Some systems can print objects over 70 cm tall in just one hour.

Yes. Modern DLP technology has evolved to process thermoplastic polymers, bridging the gap between speed and material versatility.

Key areas include medical equipment, aerospace components, energy systems, and soft robotics.

3D printing offers customization, faster prototyping, cost-effective complexity, and greater sustainability with reduced waste.

With ongoing advances in materials, speed, and automation, 3D printing is expected to revolutionize modern manufacturing by enabling scalable, smart, and highly tailored production.