Table of Contents

How to Choose the Right CNC Machining Material for Prototyping and Functional Testing

As a designer, selecting the right material for your prototype can be challenging—especially when it comes to CNC machining for rapid prototyping and functional testing. Each material has unique mechanical properties that directly affect the prototype’s performance, durability, and test outcomes. Accurate material selection ensures that your test data is reliable, which plays a key role in product development and time-to-market.

At RuiYi, we’re committed to helping you make the right material choice. With experience working with clients around the globe, we’ve produced thousands of prototypes and gained valuable insights into material behavior across various applications. Our team works closely with engineers and designers to ensure every part meets its functional requirements.

For instance, if you need a part with a movable hinge, we recommend CNC-machined polypropylene (PP) for its excellent flexibility. For small production runs—such as 20 pieces—we suggest vacuum casting using PP analog UP5690, a flexible plastic ideal for moving components that must endure repeated bending.

Common CNC Machining Materials

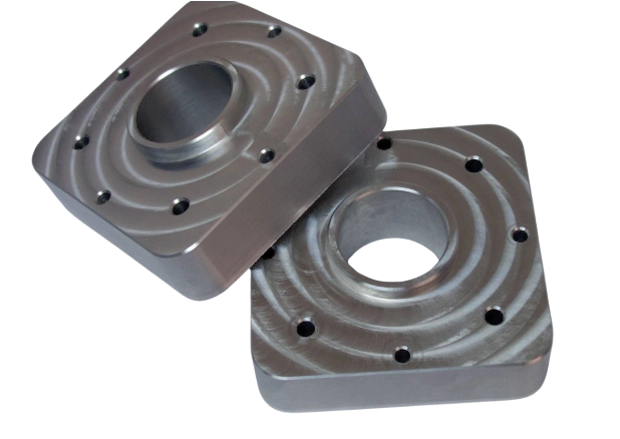

CNC milling and turning processes are compatible with a wide variety of metals and plastics. Below are some of the most commonly used materials and their typical applications:

Aluminum (6061, 6082, 7075)

6061-T6: Ideal for general-purpose CNC machining, this material offers excellent strength-to-weight ratio and can be anodized in many colors such as black, gold, and blue.

7075-T6: Commonly used in aerospace, robotics, and safety-critical applications. Though stronger than 6061, its anodized finish is less visually appealing.

Stainless Steel (304, 316, 303, 17-4PH)

Known for high strength and corrosion resistance, stainless steel is suitable for demanding environments.

Though it requires more time to machine, we provide ultra-smooth, polished finishes—comparable to the shine of a household spoon.

Engineering Plastics (POM, Nylon, PC)

POM (Delrin) and nylon are excellent choices for wear-resistant, high-precision parts.

Polycarbonate (PC) offers outstanding toughness and is ideal for transparent or impact-resistant components like lenses and enclosures.

High-Performance Plastics (PEEK, ULTEM/PEI)

Manufacturers use these materials in aerospace, automotive, and medical industries because they withstand high temperatures.

They’re more expensive but offer superior strength, thermal resistance, and chemical stability.

Specialty Materials and Technical Applications

ABS (Acrylonitrile Butadiene Styrene)

A versatile thermoplastic, ABS is hard, durable, and easy to machine.

Engineers often use it as a substitute for 3D-printed parts because it offers superior mechanical properties.

We use techniques such as precision cutting, gluing, and sanding to ensure smooth, professional-grade prototypes.

PMMA (Acrylic)

Commonly used for transparent lenses in the automotive industry and other visual components.

We offer high-quality polishing services to achieve clarity and bubble-free bonding. To protect the finish, we package the parts in custom wooden crates during shipping.

EDM (Electrical Discharge Machining)

For intricate undercuts, fine details, or sharp internal corners, we use EDM to achieve precise metal contours with excellent surface finishes.

Conclusion

Choosing the right material plays a crucial role in ensuring your prototype functions correctly, delivers accurate test results, and meets final part performance standards. Whether you need a transparent lens, a flexible hinge, or a high-strength aerospace component, RuiYi leverages its global experience, advanced equipment, and deep material expertise to tailor the right solution for you.

We’ll help you bring your designs to life—by selecting the right material and applying the best manufacturing approach.