In recent years, China has quickly become a global leader in the sheet metal working industry, offering advanced precision machining and prototyping solutions.

Whatever your needs, the market always has the right product to meet them.

Thanks to rapid technological advances, we can now complete manufacturing tasks more quickly and with greater precision.

China’s manufacturing sector has leveraged this advantage to provide higher-quality solutions to customers worldwide.

Especially in precision sheet metal working, where demand keeps rising.

Made in China: Pioneers in Precision Sheet Metal Processing

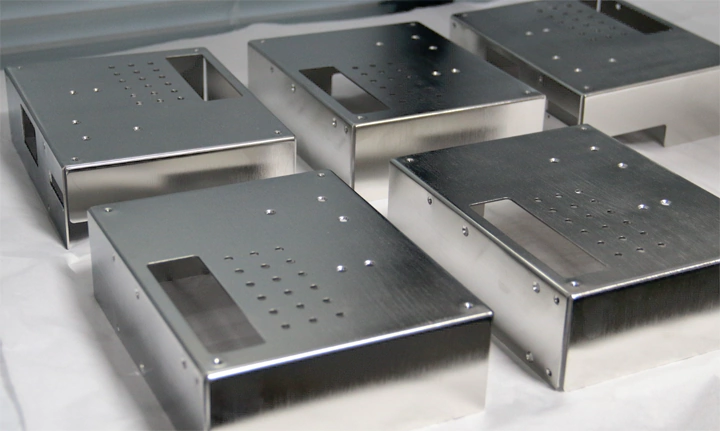

China’s manufacturing sector excels in precision sheet metal prototyping, production, and assembly.

Take RuiYi, for example. As one of China’s fastest-growing sheet metal factories, RuiYi has set the industry standard for high-quality processing through continuous innovation.

The company’s state-of-the-art infrastructure supports customized precision sheet metal prototyping, fabrication, and assembly, earning it extensive trust from clients.

Diversity of Materials Used in Sheet Metal Processing

Nearly any metal material can be processed into prototypes, including aluminum, steel, and brass.

However, the most in-demand materials are carbon steel, stainless steel, galvanized steel, aluminum, beryllium copper, nickel alloys, brass, and copper.

China’s manufacturing technology has evolved to handle these materials, meeting the diverse needs of customers.

Rapid Tooling and Injection Molding: A Tool for Efficient Manufacturing

China’s manufacturing industry offers more than traditional sheet metal processing.

It also meets the global demand for efficient, low-cost production through rapid tooling and injection molding.

Whether for rapid mass production of molds or precise molding of plastics and metals, China’s capabilities provide competitive solutions.

“We can quickly build molds to meet our customers’ needs based on their requirements, material selection, production volume, and product specifications,” said RuiYi’s senior marketing officer.

With advanced technology and flexible production methods, RuiYi provides prototyping and sheet metal solutions to customers in the electronics, medical, automotive, computer, and industrial equipment industries.

Other Technology Trends in Global Manufacturing

Besides rapid tooling and injection molding, China’s sheet metal fabrication industry continues to innovate.

Technologies like SLA rapid prototyping, vacuum casting, and extrusion prototyping are highly sought after in global manufacturing.

How to Choose the Right Manufacturing Solution

When selecting a manufacturing solution, trust companies with years of experience in the industry, particularly those with success stories across various sectors.

Customer retention rates often reflect a company’s strength and service quality. Leading companies like RuiYi, with a strong base of repeat customers, offer high-quality manufacturing and excellent service you can rely on.