- CMM on the role of three-dimensional measurement

- Research status of CMM

- Equipment Overview

- CMM future development trend

- 1. Popularization and promotion of high-speed measurement

- 2. Application of new materials and technologies

- 3. Control system improvements

- 4. Development of Measuring Machine Probes

- 5. Innovations in software technology

- Conclusion

A Coordinate Measuring Machine (CMM) is a precision instrument used to measure the physical geometrical characteristics of an object. Using a coordinate system, it performs these measurements by determining the object’s dimensions, shapes, and positions.

CMMs are essential for quality control, inspection, and reverse engineering in the manufacturing, automotive, aerospace, and electronics industries.

Since the 1960s, industrial production has advanced, driven by industries like machinery, automobiles, and aerospace, leading to the rise of three-coordinate measuring machines and 3D measurement technology.

As a new high-efficiency precision measuring instrument developed in the past 30 years, CMM has been widely used in machinery manufacturing, electronics, automotive, and aerospace industries.

It can inspect the size, shape, and mutual position of parts and components, such as the box measurement, guide rail, turbine and blade, cylinder, cam, gear, for,m, and other space profiles.

Moreover, it can also be used for scribing, centering holes, photolithography of integrated circuits, scanning of continuous surfaces, and preparing machining programs for CNC machine tools.

Because of its versatility, measuring range, high precision, high efficiency, and good performance, it can be connected with a flexible manufacturing system. It has become a class of large-scale precision instruments, so there is a “measurement center.”

CMM on the role of three-dimensional measurement

The emergence of the coordinate measuring machine (CMM) is a milestone marking the transition from classical manual measuring methods to modern automatic testing technology.

CMMs play an essential role in three-dimensional measurement technology in the following aspects:

1. Solving Complex Measurement Challenges

CMMs address the measurement of complex surface contours, including hole dimensions and positions in box parts, blades, gears, and the outer contours of vehicles and aircraft.

2. Enhancing Measurement Accuracy

High-precision CMMs achieve single-axis accuracy of up to 1 μm per meter and three-dimensional space accuracy of 1–2 μm. Shop floor CMMs provide accuracy within 3–4 μm per meter.

3. Promoting Automated Production Lines

CMMs can integrate with CNC machine tools and machining centers to form automated production lines or flexible manufacturing systems, advancing automation in manufacturing.

4. Improving Measurement Efficiency

Continuous improvements in CMM accuracy and automation significantly enhance the efficiency of three-dimensional measurement processes.

5. Leveraging Computer Technology

Electronic computers facilitate data processing, enable control functions, and reduce measurement time by over 95%.

The attached table compares the efficiency of CMMs with traditional measurement methods.

Research status of CMM

The first CMM in the world was manufactured by Britain in 1959, and its application has become quite common nowadays. According to the statistics of international professional consulting companies, the sales growth rate of CMM is around 7%-25%.

Developed countries have a higher percentage, but the growth rate decreases yearly, about 7%-10%; developing countries have a lower percentage, but the growth rate increases by about 15%-25%.

At present, the three-coordinate measuring machine is developing rapidly, the world production measuring machine manufacturers have more than 50, variety of specifications has reached more than 300 kinds.

Equipment Overview

Coordinate measuring machine manufacturers more, series of many varieties, most of which have scribing function. Germany’s Zeiss Zeiss and Leitz Letiz are famous foreign manufacturers, Italy’s DEA, the U.S. Brown @ Sharp (Brown & Shape), Japan’s Mitutoyo (Mitutoyo), and other companies.

In general, CMM machines have the following characteristics:

Accessibility and Design

a) Most machines feature a cantilevered layout, providing excellent space accessibility for mounting large parts or complete vehicles.

b) Optimized designs using AutoCAD and finite element methods ensure reasonable structures and appealing shapes.

Specialized Development

c) Strong specialized development capabilities offer more tailored software and accessories to meet diverse user needs.

Material and Construction

d) Moving parts are primarily aluminum alloy, minimizing mass for high rigidity and low inertia.

Error Compensation and Control

e) Equipped with 21 error compensation software tools to enhance accuracy cost-effectively.

f) Features a 32-bit DSP continuous trajectory control system with better performance than traditional CPUs, supporting advanced computations and internally stored high-level programs.

Advanced Probing and Software

g) Machines predominantly use Renishaw (UK) electric probes, known for their reliability and functionality.

h) Includes full-featured control and measurement software, along with specialized error correction programs.

Stability and Networking

i) Machines are highly stable, reliable, and offer long service lives.

j) CMMs are networked with computer workstations and CNC machine tools, enabling seamless integration.

Rapid Technological Growth

k) CMM technology has evolved rapidly, with CNC systems and measurement software updated every two to three years.

Standardization and Variety

l) Offers a comprehensive range of models with a high degree of standardization, generalization, and serialization.

CMM future development trend

Advanced manufacturing technology, various engineering projects, and the need for scientific experiments on the three-coordinate measuring machine constantly put forward new, higher requirements.

From the current development of three coordinate measuring machines and science and technology, production of three coordinate measuring machine requirements, in the next period, its main development trend can be summarized in the following aspects.

1. Popularization and promotion of high-speed measurement

Quality and efficiency have always been the two main indicators of the performance of various machines and the advantages and disadvantages of production processes.

The traditional concept is that the measurement speed should not be too high to ensure measurement accuracy.

As the pace of production accelerates, users require the measuring machine to ensure accuracy while meeting increasingly demanding speed requirements. Enhancing the measurement speed of CMM brings the following innovations:

Structural Improvements and Material Advancements

a) Structural design improvements and material changes optimize rigidity and reduce the mass of moving parts.

Lightweight materials like aluminum, ceramics, and synthetic materials replace conventional materials such as granite, reducing motion inertia. Thin-walled hollow structures are also being adopted.

Dynamic Performance Enhancements

b) High-speed dynamic performance relies on improved dynamic compensation capabilities. The measuring machine’s structural parameters and motion protocols are optimized to minimize dynamic errors, improve control system performance, and ensure high accuracy during high-speed measurements.

Transition to Non-Contact Probe Methods

c) Non-contact probe measurement avoids the limitations of touch methods, such as frequent acceleration, deceleration, and collisions, significantly improving measurement speed. This method enhances reliability and safety and is superior to traditional touch measurement.

The Role of Offline Programming Technology

d) Offline programming technology, supported by CAD, allows measurement program preparation in a 3D graphics environment without using the measuring machine.

This synchronizes measurement preparation with production processes, improving both measuring machine and program preparation efficiency.

By incorporating these advancements, CMMs continue to improve in speed, accuracy, and efficiency, meeting the growing demands of modern production processes.

2. Application of new materials and technologies

To ensure reliable high-speed measurement function, foreign countries attach great importance to the selection of raw materials for the research body, recently in the traditional cast iron, cast steel based on the addition of alloys, stone, ceramics, and other new materials.

Zeiss, Sheffield, Leitz, Ferranti (UK), DEA, and other major coordinate measuring machine manufacturers worldwide use most of the lightweight, good rigidity, and thermal conductivity of alloy materials to manufacture the measuring machine on the moving mechanism components.

Aluminum alloys, ceramic materials, and various synthetic materials in the CMM have been increasingly widely used.

Because of the good thermal conductivity of the new materials, when uneven temperature distribution occurs, thermal smoothness can be achieved quickly in a very short period, and thermal deformation caused by temperature changes can be minimized.

For this reason, in recent years, it has given rise to the manufacturer’s reformulation of the climax, and new varieties are emerging. The progress of technical indexes is shown in two aspects:

a) Maximum operating speeds of 15m/s or more;

b) Ambient temperature requirements can be reduced to 20 ± 4°C.

Other new technologies, such as magnetic levitation, will also be used in measuring machines and other probes.

3. Control system improvements

In modern manufacturing systems, the purpose of measurement is increasingly not limited to finished product acceptance inspection but to the entire manufacturing system to provide information about the manufacturing process to provide a basis for control.

Based on this requirement, the measuring machine must have an open control system with greater flexibility. To this end, it is possible to use the rapid development of new electronic industrial technology, especially computers, to design new high-performance/price ratio systems.

In recent years, the price of computers has decreased, while the performance is improving. Suppose you can use the mass production of inexpensive and high-performance computer templates (such as 80386, 80486) to design a special measuring machine digital control system.

In that case, you can introduce a new, inexpensive, and high-performance measuring machine control system. Alternatively, complex control systems can be compactly designed to reduce costs.

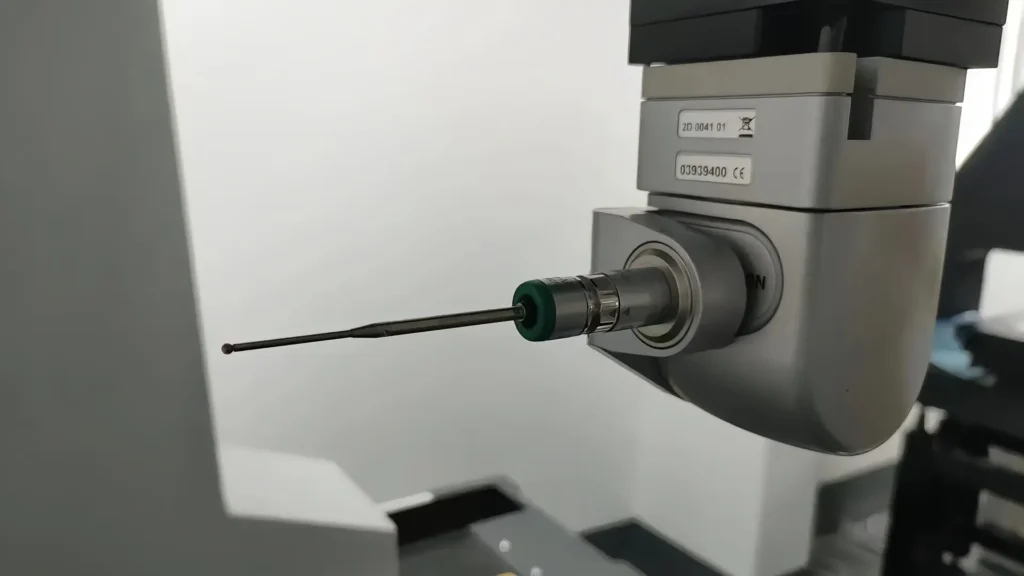

4. Development of Measuring Machine Probes

Role of Probes in CMM Accuracy

In addition to the mechanical body of the CMM, the probe is key to achieving high accuracy and is considered the core of the CMM. Improving probe performance is the most challenging aspect compared to other technical indicators.

Ideal Probe Characteristics

The ideal probe’s performance is closely linked to its parameters, such as the probe body diameter (D) and the probe rod length (L), with the L/D ratio being crucial. A higher L/D ratio improves performance, with values greater than 6 providing accuracy higher than 0.1μm and trigger movement speeds ranging from 0.5mm/s to 80mm/s.

Advancements in Probe Technology

Developing “solid-state sensor” technology is inevitable to meet these high-performance requirements, shifting detection from passive perception to active sensing and addressing issues like piezoelectric probes’ sensitivity and resistance to interference.

The Rise of Non-Contact Probes

A key trend in probe technology is the increased use of non-contact probes, especially in industries like microelectronics, where contact probes cannot measure two-dimensional patterns like integrated circuit masks.

Growth of Optical Coordinate Measuring Machines

The rapid development of optical coordinate measuring machines has focused on non-contact measurement. These machines, paired with advanced non-contact probes, offer high precision and a broad range, facilitating scanning measurements and specialized measurements of micro-parts, especially in small holes.

Future of Probe Technology

Using different types of probes, whether simultaneously or alternately, is also a significant development direction for the future of CMM technology.

5. Innovations in software technology

Software determines the measuring machine’s function and ease of use, and supports new technology developments.

To integrate CMMs into production, network communications, modeling, CAD, reverse engineering, and simulation software need to be developed.

In addition, to speed up the popularization of the use of general measurement software (DMIS) to facilitate data exchange with CAD/CAM;

Developing specialized measurement software for diverse workpieces and unifying them on a common platform is an inevitable trend in software innovation.

It can be said that the measuring machine software is one of the most rapidly developing technologies in CMM.

The development of software will make the three-coordinate measuring machine in the direction of intelligent development.

Conclusion

As a core of precision measurement, CMM has evolved to intelligent automation, advancing in materials, high-speed, non-contact tech, and integration to meet industrial demands and drive manufacturing upgrades.

What are the main types of CMMs?

- Bridge CMM: Most common for general use.

- Cantilever CMM: Used for small parts with high accuracy.

- Gantry CMM: Ideal for large parts.

- Portable CMM: Used for on-site measurements and flexibility.

What industries use CMMs?

CMMs are widely used in aerospace, automotive, manufacturing, medical devices, and other industries requiring precise quality control and dimensional analysis.

What is the accuracy of a CMM?

Accuracy depends on the machine type and configuration but can range from a few microns to sub-micron levels for high-precision models.

What is the role of software in CMM operation?

CMM software analyzes measurement data, generates reports, and integrates with CAD models to perform comparisons between actual parts and their designed specifications.

What are the common probes used in CMMs?

- Touch-trigger probes: For discrete point measurement.

- Scanning probes: For continuous surface measurements.

- Non-contact probes: Such as laser or optical probes for delicate or soft materials.

What is the advantage of using a CMM over traditional measuring tools?

CMMs provide higher accuracy, faster measurements, and the ability to measure complex geometries that traditional tools like calipers and micrometers cannot handle.

What factors affect the accuracy of a CMM?

Factors include machine calibration, temperature stability, probe type, operator skill, and part fixturing.

How is a CMM calibrated?

Calibration is done using certified reference standards to ensure the machine provides accurate measurements. Regular maintenance and environmental controls are essential to maintain accuracy.