In the world of prototype manufacturing, two prominent technologies stand out: light curing (SLA) and laser selective sintering (SLS).

Both play vital roles in the production of hand models and are widely adopted in industrial design and development.

But what sets them apart, and how do they complement one another?

Similarities Between SLA and SLS

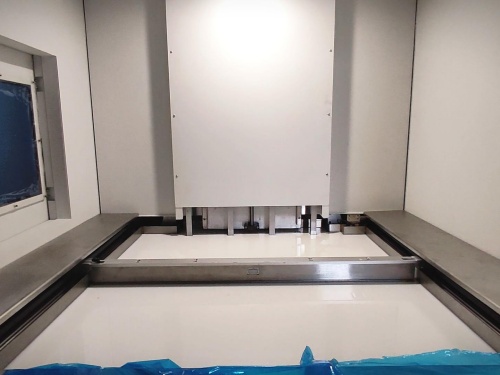

At their core, both SLA and SLS share similar principles. They build parts layer by layer based on 3D CAD models and are integral to rapid prototyping, especially during the early stages of product development.

Each method allows for quick validation of design concepts and supports functional testing and structural assessment.

Key Differences in Materials and Application

While their foundational concepts align, SLA and SLS differ significantly in material use and performance outcomes.

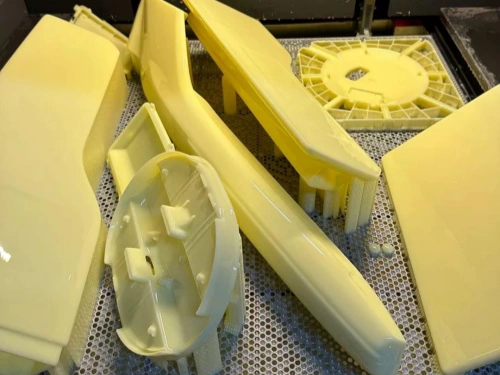

SLA (Stereolithography) utilizes liquid photosensitive resin, cured by a laser to form solid layers.

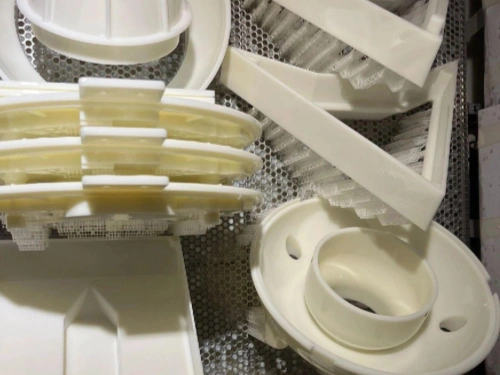

SLS (Selective Laser Sintering), on the other hand, employs powdered materials, including nylon, polycarbonate (PC), wax powders, metals, and even some ceramics.

These differences result in distinct benefits:

SLA provides higher accuracy and surface finish, making it ideal for detailed prototypes, aesthetic models, and products requiring tight tolerances.

SLS offers broader material compatibility and mechanical strength, making it suitable for functional prototypes and low-volume production of complex, durable parts—even when surface roughness and dimensional precision are secondary.

Despite SLS having a slightly rougher surface and lower precision, its versatility in material selection and ability to create structurally sound components make it highly valuable in many industrial sectors.

Choosing the Right Process

Understanding the strengths and limitations of each technology helps customers select the most suitable approach:

For high-precision models and parts with fine details or smooth surfaces, SLA is typically the better option.

For large, strong, or cost-effective parts where material variety and functional use are more critical, SLS stands out.

Advantages of SLA Technology

Mature and well-established process with reliable performance.

Direct manufacturing from CAD files—no need for molds or tooling.

Ideal for complex geometries difficult to achieve with traditional methods.

Helps visualize digital designs and reduces costly design errors.

Enables quick sample production for testing and simulation verification.

Supports remote operation and contributes to automation in production.

Limitations of SLA

High initial setup and maintenance costs.

Sensitive to environmental conditions and requires strict operational standards.

Parts are typically resin-based, limiting mechanical strength and long-term durability.

Software pre-processing is complex and requires significant computational resources.

Systems can be difficult for new users to master due to non-standard file formats.

SLA technology is predominantly controlled by a few companies, limiting access and flexibility.

Future Prospects of SLA

The evolution of SLA is trending toward faster processing, lower energy consumption, eco-friendly materials, and miniaturized systems. As technology continues to advance, SLA is expected to become more accessible, precise, and sustainable—opening the door to broader industrial and creative applications.

If you’re exploring the right rapid prototyping method for your next project, understanding these core technologies can make all the difference in achieving the perfect balance between performance, cost, and design accuracy.

Contact us: [email protected]

Website: www.ruiyi-cncmachining.com

FAQ:

SLA (Stereolithography) uses a laser to cure liquid resin layer by layer, resulting in highly detailed and smooth parts.

SLS (Selective Laser Sintering) uses a laser to fuse powdered materials like nylon or polycarbonate, creating strong, functional parts with a rougher finish.

SLA generally provides a superior surface finish and higher dimensional accuracy, making it ideal for prototypes with fine details and aesthetic requirements.

SLA: Limited to liquid photosensitive resins.

SLS: Supports a wide range of powdered materials including nylon, polycarbonate, wax, metals, and some ceramics.

Choose SLA when you need smooth surfaces, tight tolerances, and highly detailed prototypes—especially for visual models or form validation.

SLS is preferred for functional testing, structurally demanding parts, or when using specialty materials. It’s ideal for low-volume production of durable, complex parts.

SLA offers:

Excellent surface detail and precision

Tool-free direct production from CAD files

Ability to create complex geometries

Fast sample production for validation and simulation

Some downsides include:

High setup and maintenance costs

Resin parts have limited mechanical strength and durability

Complex software pre-processing and non-standard file formats

Dependency on proprietary systems and vendors

For functional parts or small-batch production, SLS can be more cost-effective due to its material flexibility and lack of support structure requirements, even if post-processing is needed.

Both technologies support rapid iteration, design validation, and functional testing early in product development, helping reduce design errors and speed up time to market.

SLA is evolving toward faster speeds, lower energy use, more sustainable materials, and compact systems—promising broader accessibility and application in the future.