Improvement of Threading Processing Technique for Drive Beveloid Gear

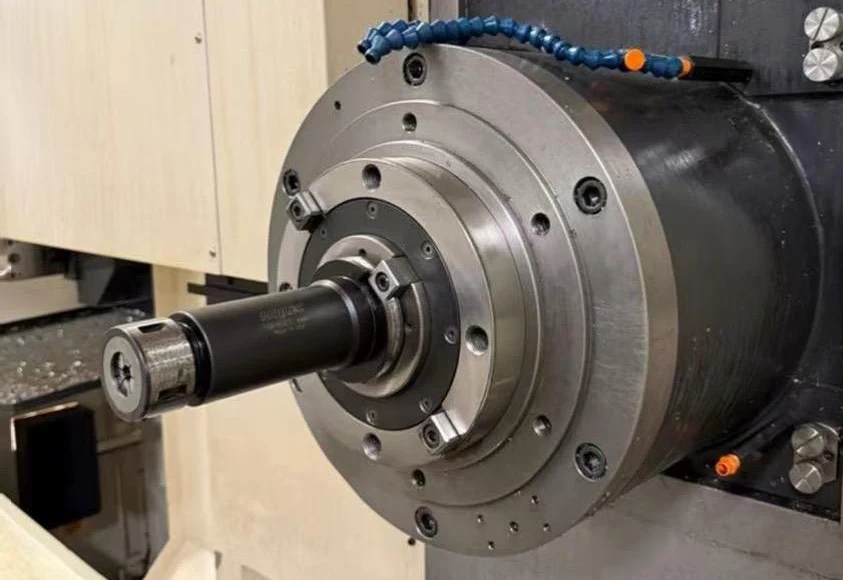

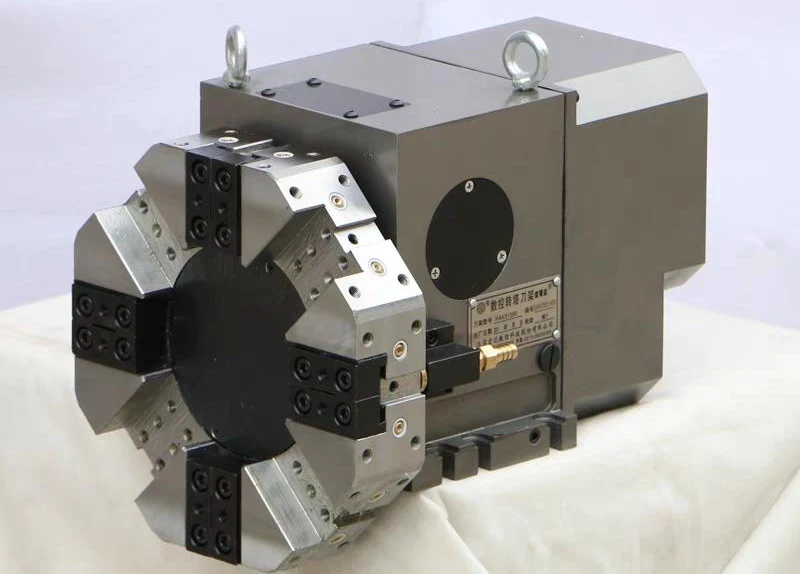

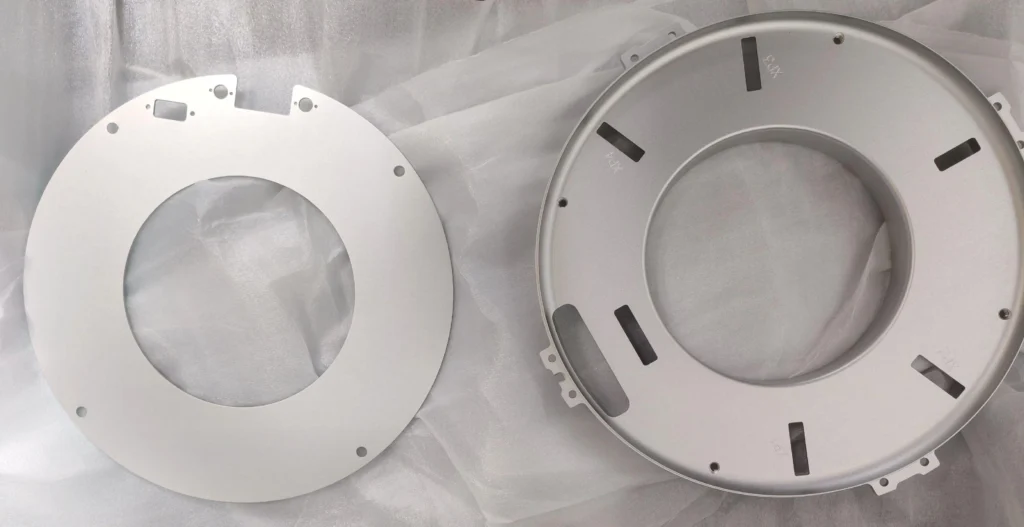

As a core component of transmission systems, drive worm gears are widely used in automobiles, construction machinery, and other fields. Their threaded ends play a critical role in transmitting power and bearing loads.