Table of Contents

Choosing the right material is vital in prototype design, as different materials offer unique properties affecting performance, cost, and manufacturing.

This article reviews common prototype materials and their selection criteria to guide optimal choices.

Plastics

ABS (Acrylonitrile Butadiene Styrene)

Designers widely use ABS for its ease of processing, high strength, and impact resistance.

It suits complex-shaped prototypes and offers excellent surface finish for painting and plating.

PLA (Polylactic Acid)

Designers often choose PLA for its biodegradability and eco-friendliness.

It’s easy to 3D print, with a low melting point and minimal warping, making it ideal for beginners.

PLA is non-toxic, odorless, and safe for indoor use.

PC (Polycarbonate)

Designers widely use polycarbonate for its high transparency, heat resistance, strength, and impact resistance, making it ideal for transparent, durable prototypes like display covers.

PMMA (Polymethyl Methacrylate)

Designers widely use PMMA, also known as acrylic, in prototype design due to its significant advantages: high transparency, suitable for prototypes requiring optical clarity.

And excellent weather resistance for outdoor use, making it resistant to yellowing and aging, ideal for high-quality transparent parts.

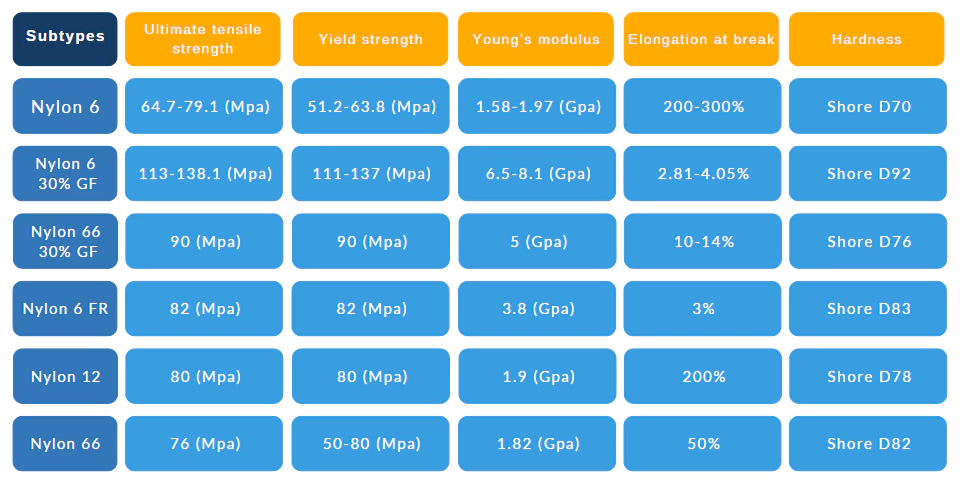

Nylon (Polyamide)

Nylon offers high strength, toughness, chemical resistance, and self-lubrication, ideal for wear-resistant, impact-resistant, and sliding-part prototypes.

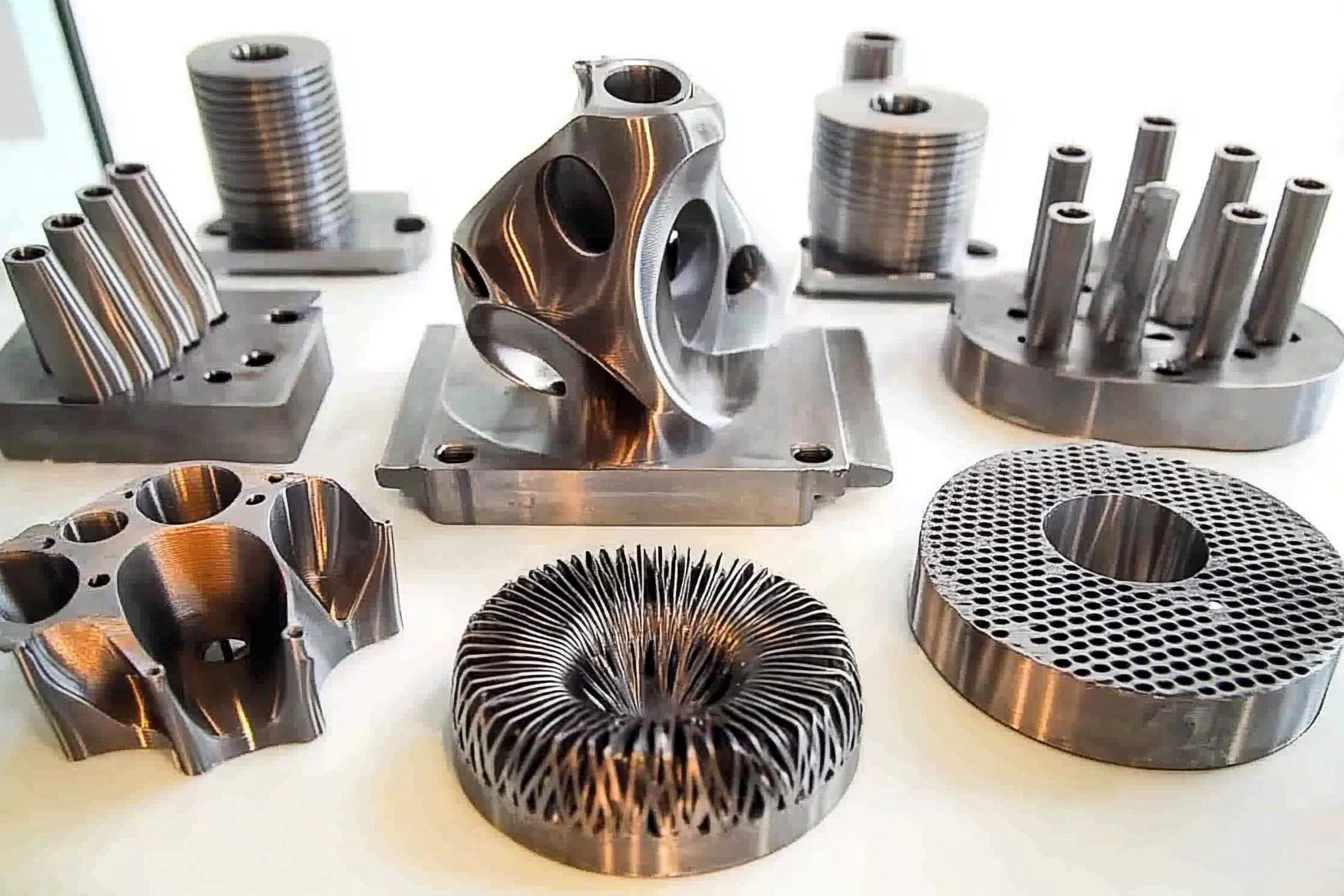

Metals

Aluminum Alloy

Designers favor aluminum alloy for its light weight, strength, machinability, and excellent thermal conductivity, making it ideal for heat-dissipating prototypes in aerospace and automotive industries.

Stainless Steel

Designers favor stainless steel for its high strength and excellent corrosion resistance.

Manufacturers can easily weld and finely process it, meeting the requirements for complex structures and high-end appearances in applications like medical and chemical equipment.

Copper Alloy

Copper alloy offers excellent electrical and thermal conductivity, easy processing, and natural antibacterial properties, ideal for electronic devices, heat dissipation, complex prototypes, and medical equipment.

Titanium Alloy

Titanium alloy combines high strength, corrosion resistance, and biocompatibility, ideal for lightweight, high-temperature, and medical or engineering prototypes.

Composite Materials

Glass Fiber Reinforced Plastic (GFRP)

GFRP, made from glass fibers and resin, offers a strong strength-to-weight ratio and corrosion resistance, ideal for lightweight, durable prototypes in harsh environments.

Its moldability suits complex shapes and mass production.

Carbon Fiber Reinforced Plastic (CFRP)

CFRP, made from carbon fibers and resin, offers an exceptional strength-to-weight ratio, making it ideal for ultra-light, high-strength prototypes.

It also provides excellent fatigue resistance and electrical conductivity, suited for long-term load-bearing or electronic applications.

Prepreg

Prepreg’s precise resin control makes it ideal for high-precision, complex prototypes.

Once cured, it provides excellent strength, rigidity, and machinability—suitable for automated processing and efficient mass production.

Composite Ceramic Materials

Composite ceramic materials, made of ceramic particles in a metal or plastic matrix, offer high-temperature stability, wear and chemical resistance, and are ideal for durable, lightweight prototypes in harsh environments.

Conclusion

Material selection greatly affects a prototype’s performance, cost, and manufacturing ease.

Designers should choose materials based on specific needs: plastics for low-cost, fast prototypes; metals for strength and durability; and composites for lightweight, high-performance parts.

Smart choices enhance design efficiency and success.

What are the common materials used for prototyping?

Prototyping materials include plastics (e.g., ABS, PLA, nylon), metals (e.g., aluminum, steel), and composites, as well as resins for 3D printing and wood for traditional modeling.

Why are plastics like ABS and PLA widely used in prototyping?

Plastics like ABS and PLA are cost-effective, easy to shape, lightweight, and versatile, making them ideal for creating functional and aesthetic prototypes.

Why is aluminum a popular choice for prototyping?

Aluminum is lightweight, strong, corrosion-resistant, and easy to machine, making it a preferred material for functional prototypes and engineering validation.

What role do resins play in prototyping?

Resins are used in additive manufacturing (e.g., SLA or DLP 3D printing) to create detailed and precise prototypes with smooth finishes, suitable for visual and functional testing.

Are composite materials used in prototyping?

Yes, composite materials like carbon fiber and fiberglass are used for lightweight and strong prototypes, especially in automotive, aerospace, and sporting goods industries.

What factors influence the choice of prototyping material?

Factors include the prototype's purpose (visual, functional, or engineering validation), material properties, cost, and the manufacturing process.

Why is steel used in prototyping?

Steel is chosen for its strength, durability, and resistance to wear, making it suitable for prototypes requiring high mechanical performance or mold inserts.

How are wood and foam used in prototyping?

Wood and foam are used for low-cost, quick prototypes to test form and design. They are especially useful in early concept development stages.

Can flexible materials be used for prototyping?

Yes, materials like TPU or silicone are used for creating flexible prototypes, such as seals, gaskets, and wearable components, for testing elasticity and durability.

How do advancements in material technology benefit prototyping?

New materials, such as bio-based plastics, high-performance polymers, and advanced composites, offer improved properties, sustainability, and compatibility with modern prototyping techniques.