With the continuous development of industrial science and technology, sheet metal chassis have become widely used.

They are applied in electronic and electrical appliances, communications, the automotive industry, and medical devices.

To meet the increasingly severe challenges in industrial manufacturing, sheet metal chassis products must have higher performance and reliability.

At the same time, they need to reduce costs while maintaining quality.

Importance of Connection Methods in Sheet Metal Chassis

In the design and manufacture of sheet metal chassis, the choice of connection method is crucial to the performance and reliability of the overall structure.

Different connection methods involve a variety of factors such as material selection, production process, and cost.

Therefore, in-depth study and comparative analysis of different connection methods are particularly important.

This paper conducts a detailed comparative analysis of connection methods.

It covers their basic principles, scope of application, advantages and disadvantages, process requirements, and costs.

The goal is to provide a comprehensive and in-depth understanding of selecting connection methods for sheet metal chassis structures.

The results of this study are expected to provide useful references for engineers, designers, and decision makers in related fields.

They aim to promote progress and innovation in sheet metal chassis manufacturing technology.

Comparative Analysis of Multiple Connection Methods

Sheet metal processing usually involves a comprehensive cold working process. This includes shearing, stamping, bending, splicing, and molding.

These processes produce parts and components in various shapes and sizes. A key feature is the consistent thickness within the same part.

Based on this, sheet metal structural parts generally have the following characteristics: light weight, high strength, and high precision.

They also offer high productivity and conductivity, making them suitable for electromagnetic shielding. Additionally, they have low cost and good performance in mass production.

Overview of Common Connection Methods for Sheet Metal Chassis

A sheet metal chassis is a finished product that is assembled from a number of sheet metal structural components through a variety of different connection methods.

Along with the wider and wider application of sheet metal structural components, their connection methods are also becoming more and more diversified.

The more commonly used connection methods mainly include threaded connection, riveting, welding and other major categories.

Threaded connections can be further divided into screw connections and bolt connections. Screw connections mainly join with riveted parts or tapped threads.

Bolt connections, on the other hand, require nuts to secure the joint.

Rivet connection has pull rivet rivet connection, pressure rivet rivet connection, turning hole rivet connection and nailless rivet connection.

Welding is mainly resistance spot welding, laser welding and argon arc welding.

Through the above connection methods, multiple chassis structural components are fixed in their corresponding positions.

This ultimately enables the complete assembly of the sheet metal chassis finished product.

Threaded Connection

Threaded connection, generally refers to the use of threaded parts or threaded parts of the connected parts will be connected to the connected parts into one flexible and removable connection.

Threaded connections are usually categorized into screw connections and bolt connections.

In bolted connections, there is no need to cut threads on the connected parts. There are also no material restrictions for the parts being connected.

This makes the construction simple. However, assembly generally requires access to both sides of the connected parts.

Bolt connection can connect different properties of the material, the use of a wider range, can provide a higher connection strength, can meet the needs of different application scenarios.

However, in some narrow or complex spaces, bolt connections can be difficult to install or maintain.

Both ends need to be accessed during the process of tightening bolts and nuts. This can reduce assembly efficiency to some extent.

As shown in Figure 1, the left side is the state of conventional bolt connection, and the right side is the installation in the flat bottom hole to ensure that the surface of the structural components is flat.

Application and Advantages of Screw Connections

When screw connection is used, it is necessary to have matching threads on the connected parts.

The more common structural forms on the structural parts of sheet metal chassis are rivet nut/stud, direct tapping/indirect tapping (hole tapping) and so on.

Based on extensive production experience, sheet metal chassis structural components are made from sheet metal, which is generally thin.

If direct tapping is used, screw connections can cause large areas of stripped threads. This leads to thread failure.

Therefore, higher strength rivet nuts are chosen to solve this problem.

Similarly, it is the thin plate characteristics of sheet metal that allow us to turn the holes before tapping, in order to increase the number of effective threads to increase the effectiveness of the screw connection.

In contrast to bolted connections, screwed connections have the “bolt” built into the structural member in advance.

This allows screws to be fastened directly during assembly without handling separate bolts.

As a result, automation becomes easier and assembly efficiency significantly improves.

Bolted connections are more often used for medium to large parts. However, in sheet metal chassis products, the parts are smaller in size.

Screw connections are sufficient to meet most usage scenarios and provide adequate strength. Therefore, screw connections are the more common method.

Another consideration in the connection of structural components in sheet metal chassis is the surface condition of the components after installation.

Normally, both ends of the bolt connection will protrude from the plane of the structural member, and a flat bottom countersunk hole is set on one side of the bolt to realize the surface leveling.

The screw connection can be directly selected countersunk head nails and with the structure of the countersunk holes to realize, but the other side will also be protruding from the plane of the structure.

The non-protruding state can facilitate the subsequent installation of the chassis into other products.

As shown in Figure 2, respectively, represents the pressure rivets and direct tapping connection, but also shows the surface of the screw after installation of the protruding state.

Riveting

Riveting is usually a method of joining multiple workpieces together using rivets.

The principle of riveting is that by applying pressure to both ends of the rivet, the end of the rivet expands and forms a tight connection with the workpiece.

According to the different types of rivets, it can be divided into pull riveting, pressure riveting and riveting, with which the corresponding will be used to pull riveting rivets and pressure riveting rivets.

Pull rivets, also known as blind rivets, are installed by pulling the rivet core using a special rivet gun. This causes the rivet body to expand, creating the rivet joint.

The pulling and riveting process is completed using special tools, such as manual, electric, or pneumatic rivet guns. The specific process is shown in Figure 3.

Pull rivets a variety of rivets, accordingly, in the sheet metal chassis structure can be countersunk holes, can also be a plane through-hole.

Selection of different rivets can be realized double-sided flat, single-sided flat, double-sided raised and other effects, according to different conditions of use to specific selection.

Pressure rivets can be divided into hollow rivets and solid rivets, which require the use of pressure riveting equipment.

Hollow rivets using riveting method, solid rivets using pressure riveting method, both need to cooperate with different riveting tooling to complete.

Pressure rivets come in various head shapes, including countersunk head, round head, and flat head.

They can also achieve different effects, such as flat on both sides, single-sided flat, or double-sided convex.

The final state of riveted structural components is shown in Figure 4. These variations allow pressure rivets to be used in different scenarios.

In addition to the above riveting methods, it is also possible to use the unique forming characteristics of sheet metal to rivet holes in sheet metal chassis structures.

The corresponding mounting holes are set as countersunk holes, and the connection is completed after riveting by the tooling.

This connection can save material costs, but its connection strength is relatively low, suitable for small strength requirements of the ordinary connection.

With the continuous updating and progress of technology, it is now possible to realize nailless riveting (as shown in Fig. 5), which is stronger and more reliable than the above mentioned riveting with flipped holes.

This method uses the unique properties of sheet metal and a specialized mold. Strong pressure deforms the material, embedding one workpiece into another.

This creates a combined structure. A common form of this connection is the dovetail shape.

In a sense, this is also considered a stamping process.

This riveting process involves extruding the material at the connection position. Cold hardening improves the mechanical properties of the material at the joint.

It does this without damaging or tearing the material. The process provides a good working environment.

It uses mechanical molding, which causes no environmental or noise pollution. It also has no negative impact on employees.

This method offers a high degree of automation. It can connect one or multiple points simultaneously.

It also allows for non-destructive testing of connection strength and quality. Additionally, it can be integrated into an automatic production line.

Due to the inherent molding characteristics of this method, pits and bumps form on the surface of sheet metal structural components.

This limits the occasions where it can be applied.

Riveting is a non-removable connection method. It is more suitable for thin plate materials, making it ideal for sheet metal structural components.

However, the riveting process usually requires specialized tools.

Welding

Welding processes commonly used for sheet metal chassis structural parts include resistance spot welding, laser welding and argon arc welding.

Resistance spot welding is a method that uses a column electrode to join the contact surfaces of two overlapping workpieces.

A specific pressure is applied, controlled, and maintained between the workpieces to create stable contact resistance.

The welding power supply controller then sends a controlled current through the contact surfaces.

This generates heat, causing the temperature to rise and the contact point to melt locally.

By controlling the heat and cooling process, a welded joint is formed. This achieves the purpose of joining the metal workpieces together.

Laser welding takes advantage of the laser beam’s excellent directionality and high power density.

The optical system focuses the laser beam onto a very small area. In a very short time, a high concentration of energy forms at the heat source area.

This causes the material to melt and then solidify, creating the weld and weld seam.

Laser welding uses high-energy laser pulses to locally heat a small area of the material.

The energy from the laser spreads into the material through heat conduction. This melts the material and forms a specific molten pool.

It is a new type of welding method, mainly for welding thin-walled materials and precision parts, which can realize spot welding, butt welding, stack welding and seal welding, etc.

Meanwhile, the depth-to-width ratio is high, and the weld width is small, with a small heat-affected zone (as shown in Fig. 6).

Argon arc welding is a welding technology that uses argon as a protective gas, also known as argon gas shielded welding.

It is around the arc welding through the argon protective gas, the air will be isolated outside the weld zone, to prevent oxidation of the weld zone.

Argon arc welding technology is based on the principle of ordinary arc welding. It uses argon gas to protect the metal welding consumables.

High current melts the welding consumables and the welded substrate into a liquid state, forming a molten pool.

This allows the welded metal and consumables to achieve metallurgical bonding.

The continuous flow of argon gas prevents the welding consumables from contacting oxygen in the air. This stops oxidation of the consumables.

As a result, argon arc welding can be used for stainless steel, iron, and other metal hardware.

In summary, the respective characteristics of the three welding methods:

① spot welding can effectively save material, and simple operation, low cost, high efficiency, but its welding strength is general, the precision is relatively general, the requirements of the equipment is not very high.

② The use of laser welding in sheet metal structural components results in minimal deformation. The weld seam is flat and aesthetically pleasing.

Welding speed is fast, with little or no need for post-weld treatment. The weld quality is high, with no porosity.

The process can be precisely controlled. The laser has a small focal point and high positioning accuracy. It is also easy to automate.

But it is also based on this, its equipment and tooling precision requirements are very high, and the cost of the equipment itself is high.

③ Argon arc welding is simple to operate and can effectively avoid oxidation and nitriding during the welding process.

It produces uniform, dense welds with high welding strength.

However, argon arc welding involves high costs for skilled welders and gas equipment.

It also requires careful planning for gas supply and handling, along with consideration of its environmental impact.

Welding less connection sheet metal

Although welding is a conventional and reliable connection process, welding is usually chosen less frequently for connection on sheet metal chassis.

This is mainly because of the following considerations:

①Welding is a relatively complex process, requiring higher skills from employees and more costly investment in equipment;

② The existing sheet metal chassis prioritizes the use of treatment-free sheet metal.

Welding, however, requires an additional surface treatment process to cover weld scars and improve the surface appearance.

This extra step extends the overall production cycle. At the same time, it also significantly increases the cost.

③ Structural components in the completion of welding is irreversible, non-detachable, which will have a certain impact on the later maintenance and replacement of spare parts.

Connection of structural features in sheet metal

Sheet metal parts have excellent plasticity, which is a property determined by the material itself. This allows them to be formed into various structural features.

These features can be created through processes such as drop-opening and bending molding.

For example, the most common clips on the chassis include the previously mentioned nail-free riveting and riveting with rivet holes.

These methods can also achieve the connection function. The parts are assembled by fitting together with each other.

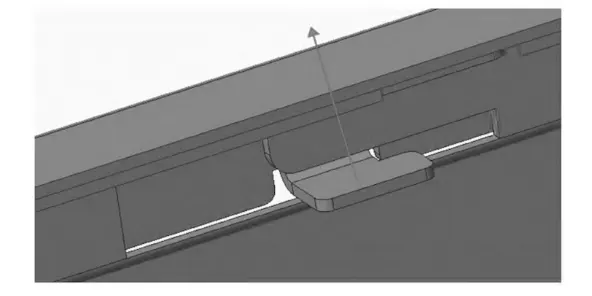

As shown in Figure 7, the structural components use a molding method.

One side has a hole, and the other side is bent. This design eliminates the need for additional parts.

After sliding into place, the connection is completed. It effectively restricts the movement of the structural components in the vertical direction.

This type of connection can eliminate screws, rivets, and no need for welding, which can save material costs.

It also avoids thermal deformation caused by welding and is more environmentally friendly.

Its operation is convenient, processing costs are lower, easy to disassemble and replace.

However, the use of this method requires the component’s shape and bending angles to be designed in advance.

If not properly planned, it may result in weak or unstable connections.

After assembly, the connection may have lower strength and can only be used in areas with low strength requirements.

Conclusion

Threaded connections, riveting, and welding are widely used in the assembly of chassis structural components.

Among these methods, screw connections make up the largest proportion of all threaded connections.

The reason for this is that the screw connection has excellent overall performance. It provides high-strength support and reliable connection strength.

It can adapt to complex and diverse environments. In addition, it is easy to operate and suitable for automated production.

At the same time, the specifications of screws on the market in a wide variety of low-cost.

Riveting requires special tools to realize, its connection is basically irreversible, inconvenient to disassemble.

Welding requires more specialized skills for employees and higher equipment costs.

However, the strength of the welded connection is sufficiently reliable and can be sealed, there is no substitute.

Connections in the form of structural features can save a lot of operating costs, but their connection strength is poor.

There are a variety of connection methods available for the assembly of structural components of sheet metal chassis (see Table 1), each with different characteristics.

In selecting the connection method, it is necessary to consider factors such as the purpose of the structural component, the environment in which it is to be used, the manufacturing cost and the maintenance requirements.

Often, complex chassis structures may also utilize a combination of connection methods to achieve optimal performance, productivity and economic efficiency.

FAQ:

The most commonly used connection methods in sheet metal chassis assembly include threaded connections (screw and bolt), riveting (pull rivets, pressure rivets, and nailless rivets), welding (resistance spot welding, laser welding, argon arc welding), and structural feature-based interlocking connections.

Screw connections require tapped threads or rivet nuts in the sheet metal, allowing pre-installed fasteners and easy automation. Bolt connections, on the other hand, use nuts and don’t require internal threading, but typically require access to both sides during assembly.

Rivet connections offer a permanent and stable joint, ideal for thin sheet metal. They come in various forms—pull rivets, pressure rivets, and nailless rivets—each adaptable for different structural and surface finish requirements, while ensuring vibration resistance and durability.

Laser welding is best used for precision and high-quality welds in thin sheet metal parts. It offers minimal deformation, high welding speed, and clean seams. However, it requires high-end equipment and precise control, making it more suitable for high-value or automated production lines.

Although reliable, welding in sheet metal chassis is less preferred due to its complexity, irreversible joints, post-weld surface treatment requirements, and high labor and equipment costs. It’s generally avoided unless structural strength or sealing is essential.

Nailless riveting uses strong localized pressure and mold-based deformation to embed one sheet metal part into another without traditional fasteners. It offers a high-strength, clean, and automated joining solution with no environmental or noise pollution.

These connections use the inherent plasticity of sheet metal to create interlocking shapes through bending and slotting. They eliminate the need for fasteners or welding, lowering costs and simplifying assembly, though they offer lower structural strength and require precise design planning.

Screw connections are most suitable for automation due to their ease of installation, compatibility with rivet nuts, and integration into robotic assembly lines. They reduce assembly time and improve consistency in mass production.

Engineers should consider the mechanical strength required, cost, ease of assembly, disassembly needs, surface aesthetics, automation compatibility, and operating environment. Often, a hybrid of connection methods is used for optimal performance and manufacturability.

Threaded connections offer the highest serviceability due to their removability. Riveting and welding create permanent joints, making future maintenance or part replacement difficult. Structural feature-based connections can simplify disassembly but may compromise joint strength.